Three-dimensional porous lithium manganate thin film electrode, preparation method and application thereof

A three-dimensional porous lithium manganate, porous lithium manganate technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems affecting electrochemical performance and safety, capacity decay, no reports, etc., and achieve excellent rate. performance and cycle stability, enhanced cycle performance and safety, and the effect of increasing the electrochemical reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

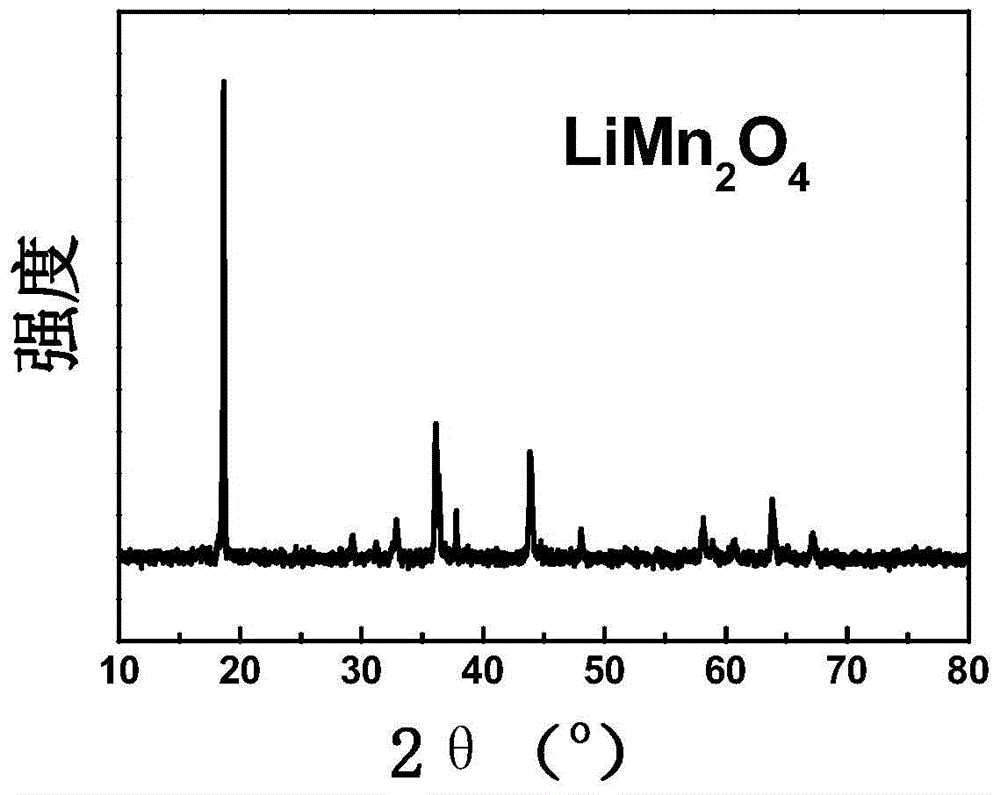

Image

Examples

Embodiment 1

[0027] 1) The pretreatment of the polymer porous membrane in the embodiment of the present invention adopts the following steps: prepare 500 mL of a strong oxidizing acid solution with deionized water as a solvent, mix hydrochloric acid and sulfuric acid at a molar ratio of 1:1, and then add deionized Water to 500mL to obtain 500mL strong oxidizing acid solution, wherein the total mass percentage of hydrochloric acid and sulfuric acid is 15%. A polymer porous membrane (porous polyethylene film, Nitto SUNMAP) was soaked in the strong oxidizing acid solution, and hydrophilized at 60° C. for 6 hours. The polymer porous membrane is washed to neutrality with deionized water to obtain a polymer porous membrane with a hydrophilic surface.

[0028] 2) Uniformly disperse 1.58g of potassium permanganate and 1.42g of sodium sulfate in 50mL of deionized water to obtain a chemical bath deposition reaction solution (ie, an electroless plating solution). Then immerse the porous polymer film...

Embodiment 2

[0034] 1) The pretreatment of the polymer porous membrane in the embodiment of the present invention adopts the following steps: prepare 500 mL of a strong oxidizing acid solution with deionized water as a solvent, mix hydrochloric acid and sulfuric acid at a molar ratio of 1:1, and then add deionized Water to 500mL to obtain 500mL strong oxidizing acid solution, wherein the total mass percentage of hydrochloric acid and sulfuric acid is 15%. A polymer porous membrane (porous polyethylene film, Nitto SUNMAP) was soaked in the strong oxidizing acid solution, and hydrophilized at 60° C. for 6 hours. The polymer porous membrane is washed to neutrality with deionized water to obtain a polymer porous membrane with a hydrophilic surface.

[0035] 2) Uniformly disperse 1.58g of potassium permanganate and 1.42g of sodium sulfate in 50mL of deionized water to obtain a chemical bath deposition reaction solution (ie, an electroless plating solution). Then immerse the porous polymer film...

Embodiment 3

[0039] 1) The pretreatment of the polymer porous membrane in the embodiment of the present invention adopts the following steps: prepare 500 mL of a strong oxidizing acid solution with deionized water as a solvent, mix hydrochloric acid and nitric acid at a molar ratio of 1:1, and then add deionized Water to 500mL to obtain 500mL strong oxidizing acid solution, wherein the total mass percentage of hydrochloric acid and nitric acid is 15%. A polymer porous membrane (porous polyethylene film, Nitto SUNMAP) was soaked in the strong oxidizing acid solution, and hydrophilized at 60° C. for 6 hours. The polymer porous membrane is washed to neutrality with deionized water to obtain a polymer porous membrane with a hydrophilic surface.

[0040] 2) Uniformly disperse 7.9g of potassium permanganate and 7.1g of sodium sulfate in 60mL of deionized water to obtain a chemical bath deposition reaction solution. Then immerse the porous polymer film with a hydrophilic surface into the above c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com