Preparation method for high-strength wheat protein fiber

A wheat protein fiber and high-strength technology, which is applied in the field of wheat protein resource utilization, can solve the problems of poor physical and mechanical properties and chemical stability of regenerated protein fiber, low strength of wheat protein fiber, and shortened production cycle. The effect of improving tensile strength and elongation at break and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

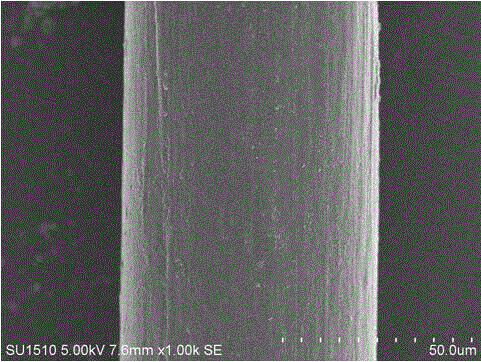

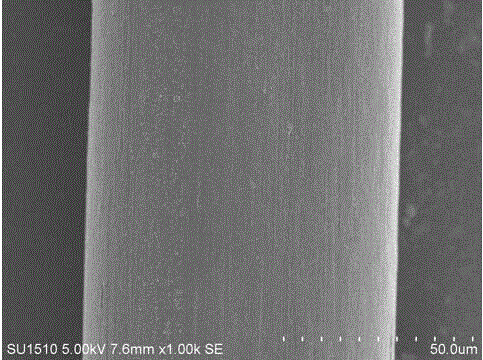

Image

Examples

Embodiment 1

[0017] Example 1: Add gluten powder to 65% ethanol solution according to the ratio of material to liquid 1:30, and stir in a water bath at 30°C for 2.5h to form a suspension, centrifuge at 4500r / min for 20min, and take the supernatant , the remaining solid was repeatedly extracted twice in the same way, the supernatants were mixed, concentrated by rotary evaporation, and then dried to obtain gliadin. After the final extraction of the centrifuged solid, add water according to the ratio of material to liquid 1:20, and adjust the pH to 10, then place it in a water bath at 55°C and stir for 2.5 hours, then centrifuge at 4500r / min for 20 minutes, take the supernatant, and repeat the extraction 2 times, the supernatants were combined, and ethanol was added to adjust the ethanol mass concentration to 65%, and the pH of the solution was adjusted to 7, then placed in a refrigerator at 4°C for 12 hours, and the precipitate obtained by centrifuging at 4500r / min for 20min was dried, namely...

Embodiment 2

[0019] Example 2: After purifying glutenin and gliadin according to the above method, mix glutenin and gliadin in a ratio of 2:1, add 6M guanidine hydrochloride and 1% sodium sulfide, and make a protein concentration of 15%. Protein solution, adjust the pH to 8, process the above solution under the microwave power of 30W / g solution for 2min to obtain the spinning stock solution, use a 1mL syringe to extrude the silk while it is hot, and enter the coagulation bath containing 5% sodium sulfate and 10% sulfuric acid, and the coagulation time 30min, and then the tow is taken out and washed three times in hot water, and stretched 3-6 times in length. The obtained fibers were heated at 85°C and 125°C for 1 hour respectively, and then fumigated with 25% glutaraldehyde steam for 48 hours to obtain wheat protein fibers which were the desired fibers.

Embodiment 3

[0020] Example 3: After the glutenin and gliadin were purified according to the above method, the glutenin and gliadin were mixed in a ratio of 1:2, and then 8M urea and saturated cysteine were added to make a protein concentration of 18 % protein solution, adjust the pH to be 7, process the above solution under the microwave power 26W / g solution for 3min to obtain the spinning stock solution, use a 1mL syringe to extrude the silk while it is hot, and enter it into a coagulation bath containing 15% sodium sulfate and 15% sulfuric acid. The coagulation time is 15 minutes, and then the tow is taken out and washed three times in hot water, and stretched 3-6 times in length. The obtained fibers were heated at 85°C and 125°C for 1 hour respectively, and then fumigated with formaldehyde steam for 48 hours to obtain wheat protein fibers which were the desired fibers.

[0021] Comparison of the properties of the obtained wheat protein fiber with that of wool:

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com