A kind of preparation method of polyvinylidene fluoride based heat conduction composite material

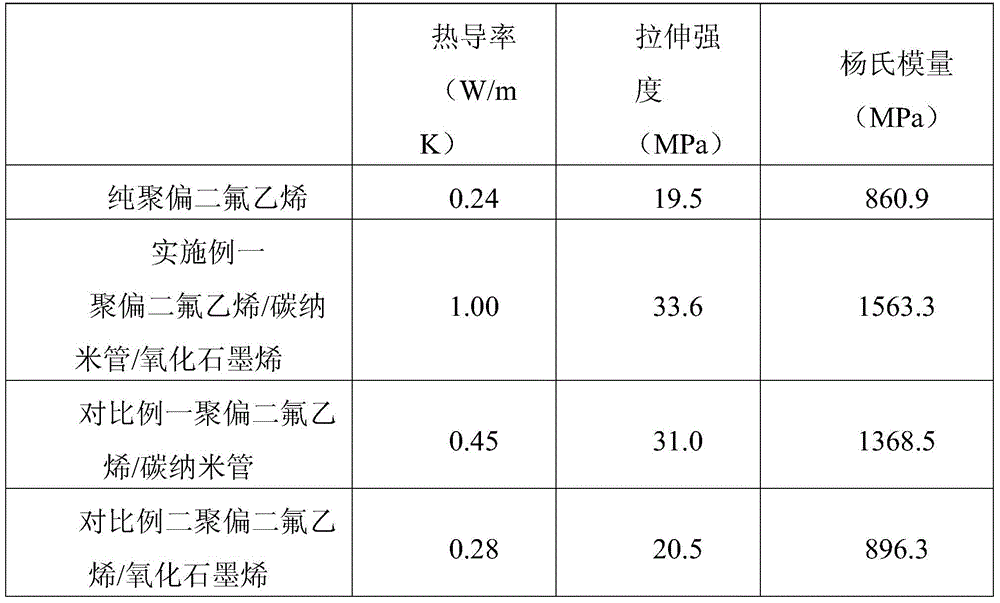

A technology of polyvinylidene fluoride and heat-conducting composite materials, which is applied in the field of preparation of heat-conducting composite materials, can solve the problems of composite materials such as decline in mechanical properties, dispersion, poor interface interaction, and slow improvement, so as to improve mechanical properties and promote mutual dispersion , the effect of expanding the layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

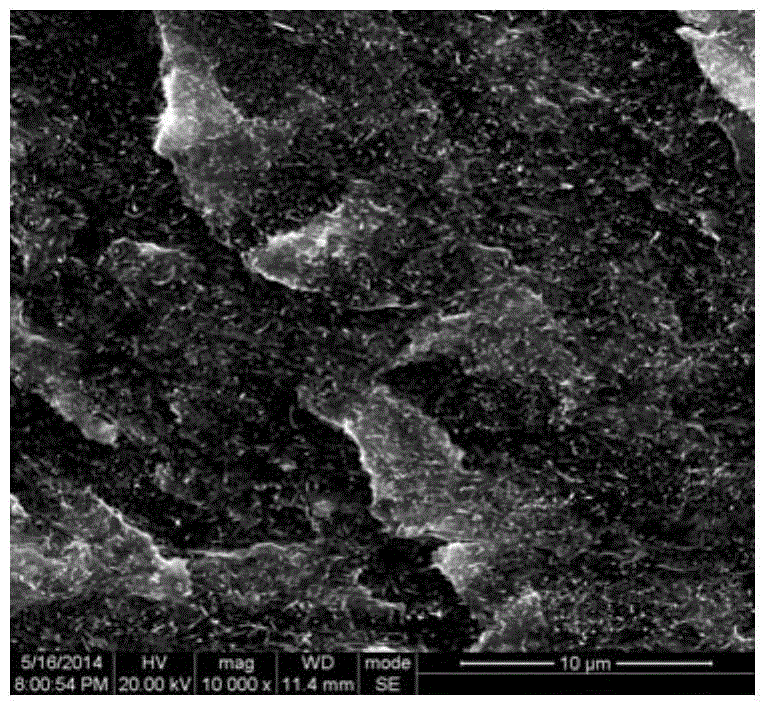

Image

Examples

Embodiment 1

[0021] A preparation method of a polyvinylidene fluoride-based thermally conductive composite material, the steps of which are:

[0022] A, preparation of graphene oxide / N,N-dimethylformamide solution:

[0023] The 25% graphene oxide aqueous solution prepared by the Hummers method is dissolved in N,N-dimethylformamide and distilled under reduced pressure, the volume ratio of the graphene oxide aqueous solution to N,N-dimethylformamide 2:1, the temperature of vacuum distillation is 55°C, and the time is 8h; after the distillation, the distillate is ultrasonically treated, the ultrasonic treatment time is 1h, and the ultrasonic efficiency is 5×10 4 W / m 3 .

[0024] The Hummers method is an existing method for preparing graphene oxide through a redox reaction. For details, see Hummers WS, Offeman RE. Preparation of Graphite Oxide. Journal of the American Chemical Society, 1958, 80: 1339-1339.

[0025] B. Composite material preparation:

[0026] Add polyvinylidene fluoride and...

Embodiment 2

[0035] A, preparation of graphene oxide / N,N-dimethylformamide solution:

[0036] The 50% graphene oxide aqueous solution prepared by the Hummers method is dissolved in N,N-dimethylformamide and distilled under reduced pressure, the volume ratio of graphene oxide aqueous solution to N,N-dimethylformamide 2:1, the vacuum distillation temperature is 60°C, and the distillation time is 12h; after the distillation, the distillate is ultrasonically treated, the ultrasonic treatment time is 2h, and the ultrasonic efficiency is 2.5×10 4 W / m 3 .

[0037] B. Preparation of composite materials:

[0038] Add polyvinylidene fluoride and carbon nanotubes to the distillate in step A, and stir magnetically for 6 hours at 90°C to obtain a mixed solution. The mass ratio of polyvinylidene fluoride, carbon nanotubes and graphene oxide is 90:8 : 2; then the mixed solution was ultrasonically treated at 90°C, and then heated to 120°C to obtain a viscous solution, and then the viscous solution was ...

Embodiment 3

[0040] A, preparation of graphene oxide / N,N-dimethylformamide solution:

[0041] The 35% graphene oxide aqueous solution prepared by the Hummers method is dissolved in N,N-dimethylformamide and distilled under reduced pressure, the volume ratio of the graphene oxide aqueous solution to N,N-dimethylformamide 2:1, the vacuum distillation temperature is 58°C, and the distillation time is 10h; after the distillation, the distillate is ultrasonically treated, the ultrasonic treatment time is 1.5h, and the ultrasonic efficiency is 3×10 4 W / m 3 .

[0042] B. Preparation of composite materials:

[0043]Add polyvinylidene fluoride and carbon nanotubes to the distillate in step A, and stir magnetically for 4 hours at 85°C to obtain a mixed solution. The mass ratio of polyvinylidene fluoride, carbon nanotubes and graphene oxide is 90:5 : 5; then the mixed solution was ultrasonically treated at 85°C, heated to 110°C to obtain a viscous solution, and then put into a 60°C oven to dry the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com