A method for forming large-scale isostatic graphite products

A molding method and isostatic pressing technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of time-consuming and energy consumption, complex production methods and processes, and achieve simplified isostatic pressing molding process, high yield and high bulk density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

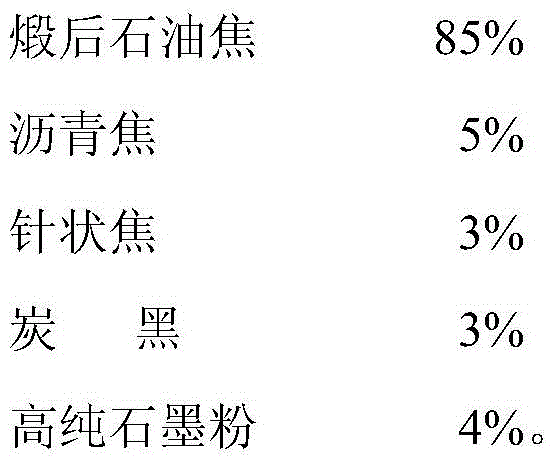

[0046] Raw material formula (mass percentage):

[0047]

[0048] Isostatic graphite molding method:

[0049] (1) Take the raw materials according to the above formula, grind the raw needle coke, calcined petroleum coke, and pitch coke into powder with a particle size greater than 325 mesh and less than 200 mesh, and then grind the needle coke, calcined petroleum coke, and pitch coke into powder , carbon black, and high-purity graphite powder with a purity of 99.99% were mixed at a temperature of 135° C. for 0.5 hour, and dry-blended into mixture A;

[0050] Take the modified asphalt (accounting for 38% of the weight of mixture B), first heat it to 180°C, then add oleic acid (accounting for 0.5% of the weight of mixture B) to form a modified asphalt mixture, keep warm and stir for 40min;

[0051] For the first time, add 65% of the modified asphalt mixture to mixture A, and carry out wet mixing at a temperature of 160-180°C. The time for the first wet mixing is 60 minutes, a...

Embodiment 2

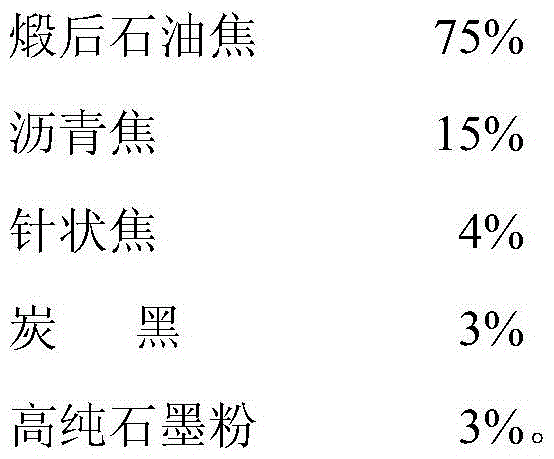

[0058] Raw material formula (mass percentage):

[0059]

[0060] Isostatic graphite molding method:

[0061] (1) Take the raw materials according to the above formula, grind the raw needle coke, calcined petroleum coke, and pitch coke into powder with a particle size greater than 325 mesh and less than 200 mesh, and then grind the needle coke, calcined petroleum coke, and pitch coke into powder , carbon black, and high-purity graphite powder with a purity of 99.99% were mixed at a temperature of 135° C. for 1.0 hour, and dry-blended into mixture A;

[0062] Take the modified asphalt (accounting for 40% of the weight of the mixture B), first heat it to 200°C, then add oleic acid (accounting for 0.5% of the weight of the mixture B) to form a modified asphalt mixture, keep warm and stir for 30min;

[0063] For the first time, add 60% of the modified asphalt mixture to mixture A, and carry out wet mixing at a temperature of 160-180°C. The time for the first wet mixing is 60 mi...

Embodiment 3

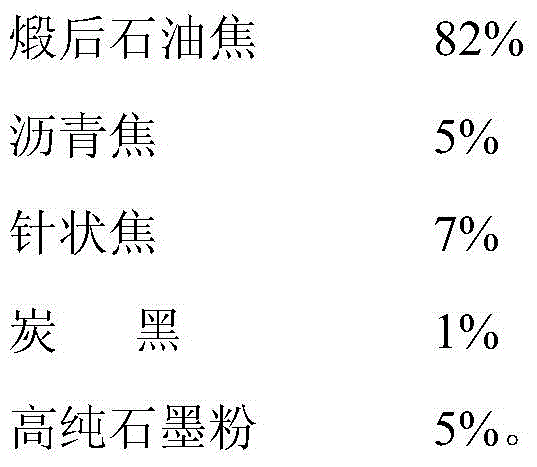

[0070] Raw material formula (mass percentage):

[0071]

[0072] Isostatic graphite molding method:

[0073] (1) Take the raw materials according to the above formula, grind the raw needle coke, calcined petroleum coke, and pitch coke into powder with a particle size greater than 325 mesh and less than 200 mesh, and then grind the needle coke, calcined petroleum coke, and pitch coke into powder , carbon black, and high-purity graphite powder with a purity of 99.99% were mixed at a temperature of 135° C. for 1.0 hour, and dry-blended into mixture A;

[0074] Take the modified asphalt (accounting for 42% of the weight of mixture B), first heat it to 220°C, then add oleic acid (accounting for 0.5% of the weight of mixture B) to form a modified asphalt mixture, keep warm and stir for 60min;

[0075] For the first time, add 65% of the modified asphalt mixture to mixture A, and carry out wet mixing at a temperature of 160-180°C. The time for the first wet mixing is 60 minutes, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com