A cement grinding aid using industrial waste residue as raw material and its preparation method

A technology for cement grinding aid and industrial waste residue, applied in the field of cement, can solve the problems of less than half of the comprehensive utilization rate, restricting the application of industrial waste residue, prolonging the setting time of cement, etc., and achieves good application prospects, excellent grinding aid effect, and dispersion effect. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

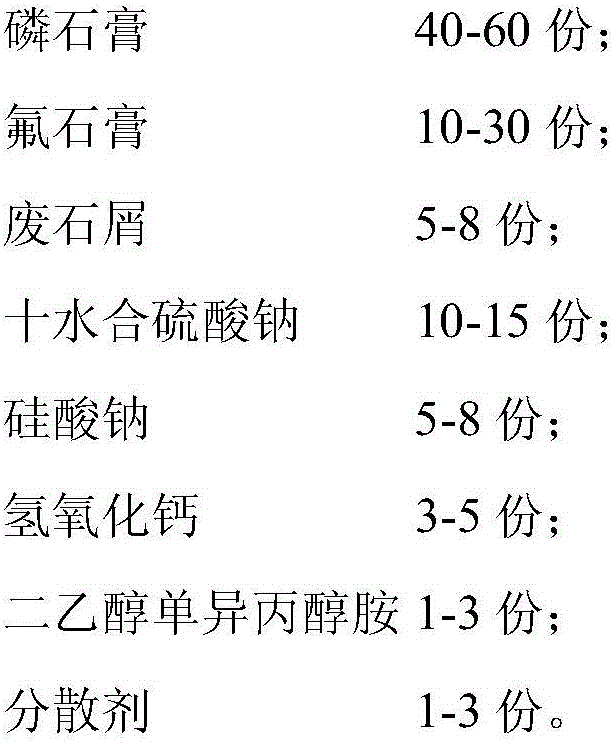

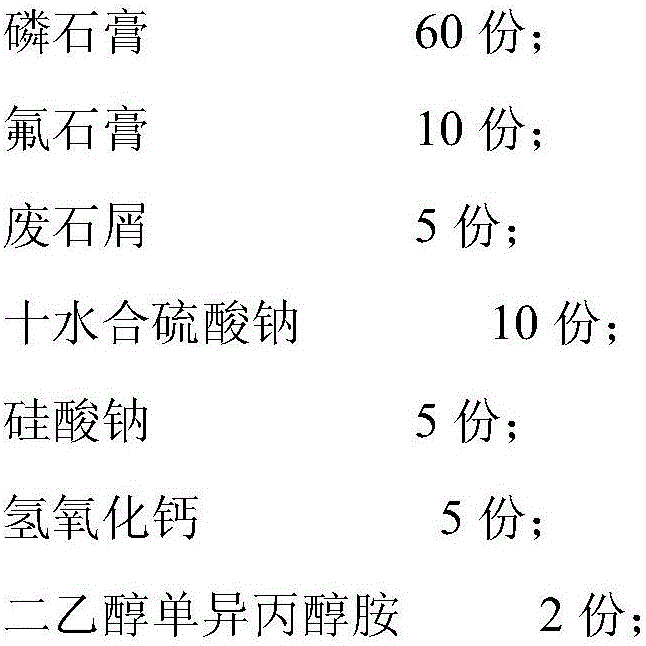

[0021] A cement grinding aid using industrial waste residue as raw material, which is made of the following components in mass percentage:

[0022]

[0023]

[0024] Wherein, the preparation method is: (1) grinding 60 parts of phosphogypsum, 10 parts of fluorogypsum and 5 parts of waste rock into fine powder, (2) grinding 3 parts of polyvinylpyrrolidone, 10 parts of sodium sulfate decahydrate and Add 5 parts of sodium silicate into the aqueous solution of 90% ethanol, and dissolve completely, (3) add fine powdered phosphogypsum, fluorine gypsum and waste rock chips into the dispersant solution, and stir well, (4) put The mixed solution was dried at 150°C, and ground into a mixed fine powder of 200 microns, (5) the mixed fine powder was added to a dry powder mixer, 5 parts of calcium hydroxide and 2 parts of diethanol monoisopropanolamine were added, Forms a finely powdered cement grinding aid.

[0025] The fineness of the invention (200 micron standard filter sieve filt...

Embodiment 2

[0027] A cement grinding aid using industrial waste residue as raw material, which is made of the following components in mass percentage:

[0028]

[0029] Among them, the preparation method is: (1) grinding 40 parts of phosphogypsum, 30 parts of fluorogypsum and 5 parts of waste rock chips into fine powder, (2) grinding 3 parts of sodium polyepoxysuccinate, 10 parts of decahydrate Add sodium sulfate and 5 parts of sodium silicate into the aqueous solution and dissolve them completely. (3) Add the fine powdered phosphogypsum, fluorogypsum and waste rock chips into the dispersant solution and stir them well. (4) Mix the Dry the liquid at 100°C and grind it into a mixed fine powder of 160 microns. (5) Add the mixed fine powder to a dry powder mixer, add 5 parts of calcium hydroxide and 2 parts of diethanol monoisopropanolamine to form Fine powder cement grinding aid.

[0030] The fineness of this invention (200 micron standard filter sieve filtration) has reduced 8%, and sp...

Embodiment 3

[0032] A cement grinding aid using industrial waste residue as raw material, which is made of the following components in mass percentage:

[0033]

[0034]

[0035] Wherein, the preparation method is as follows: (1) grinding 40 parts of phosphogypsum, 18 parts of fluorogypsum and 8 parts of waste rock into fine powder, (2) grinding 3 parts of sodium polyaspartate, 15 parts of decahydrate Sodium sulfate and 8 parts of sodium silicate are added in the aqueous solution of 45% ethanol, and dissolve completely, (3) finely powdered phosphogypsum, fluorogypsum and waste rock chips are added to the dispersant solution, and fully stirred evenly, ( 4) Dry the mixed solution at 130°C and grind it into a mixed fine powder of 160 microns, (5) Add the mixed fine powder to a dry powder mixer, add 5 parts of calcium hydroxide and 3 parts of diethanol monoisopropyl Alcohol amines form fine powder cement grinding aids.

[0036] The fineness of this invention (200 micron standard filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com