Making method of dietary therapy fermented leaf mustard

A production method and mustard technology, which are applied in the directions of microorganism-based methods, food preparation, biochemical equipment and methods, etc., can solve the problems of unrelated breeding medium and fermentation medium, and low yield of target products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

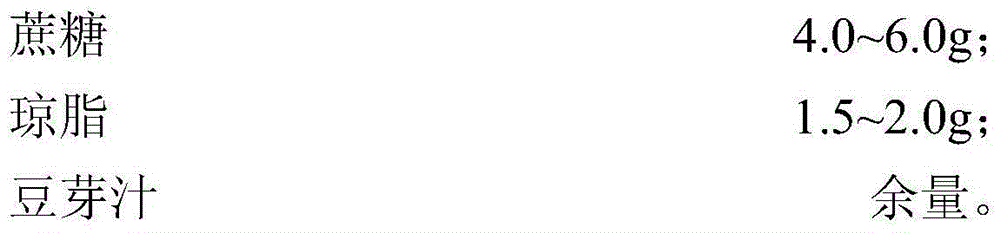

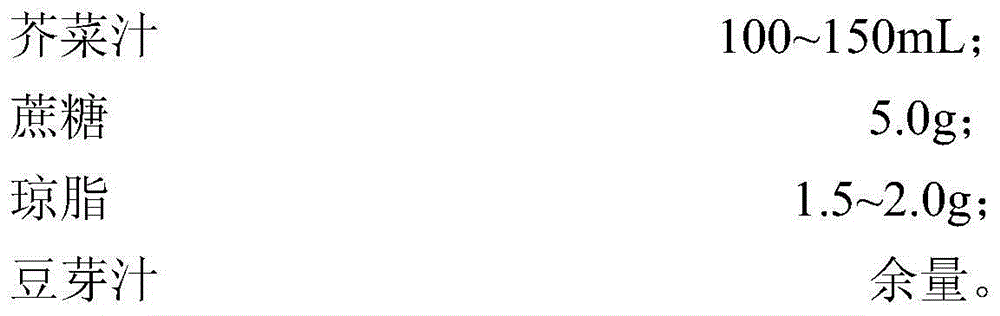

preparation example Construction

[0106] (h) The mustard juice is prepared by directly squeezing the mustard juice.

[0107] In the embodiment of the present invention, Bacillus natto 10261 and Bacillus natto 10263 adopt the prior art, and Bacillus natto 10261 comes from China Industrial Microorganism Culture Collection Center (CICC), address: 24 Jiuxianqiao Middle Road, Chaoyang District, Beijing No. 6 building; the storage date is 2002, and the strain maintenance number is 10261; Bacillus natto 10263 is from the China Industrial Microbiology Culture Collection Center (CICC), address: Courtyard 6, No. 24, Jiuxianqiao Middle Road, Chaoyang District, Beijing Building No. 1; the storage date was 2002, and the strain maintenance number was 10263; Lactobacillus casei Shirota was from Yakult (Shanghai) Co., Ltd.; the mouse anti-PQQ IgG monoclonal antibody PQQ-mAb was a commercially available product, purchased from Jiaxing Yuanke Biotechnology Co., Ltd., the product number is YK-Ab-013.

Embodiment 1

[0109] The present invention prepares fermented mustard greens rich in NK and PQQ through selection and co-fermentation of Bacillus natto and Lactobacillus casei, comprising the following steps:

[0110] (1) Breeding of Bacillus natto BN-NKPQQ-RWX-403 with high yield of NK and PQQ

[0111] Using the substrate-induced adaptive strategy, the high-yield NK and PQQ Bacillus natto BN-NKPQQ-RWX-403 was obtained through genome rearrangement and high-throughput screening technology. The obtained Bacillus natto 10261 and 10263 producing NK and PQQ were subjected to nitrosoguanidine mutagenesis respectively; then the offspring were mixed for mutagenesis, and cell fusion was carried out (fusogenic agent was polyethylene glycol 4000), subcultured, Realized genome shuffling, optimized and integrated the dominant mutations of all mutagenized progenies of Bacillus natto 10261 and 10623, and bred a high-yield NK and PQQ Natto with high yield, vigorous growth, stable genetics, and suitable as ...

Embodiment 2

[0123] The present invention prepares fermented mustard greens rich in NK and PQQ through selection and co-fermentation of Bacillus natto and Lactobacillus casei, comprising the following steps:

[0124] (1) Breeding of Bacillus natto BN-NKPQQ-RWX-403 with high yield of NK and PQQ

[0125] Using the substrate-induced adaptive strategy, the high-yield NK and PQQ Bacillus natto BN-NKPQQ-RWX-403 was obtained through genome rearrangement and high-throughput screening technology. The obtained Bacillus natto 10261 and 10263 producing NK and PQQ were respectively subjected to nitrosoguanidine mutagenesis; then the offspring were mixed for mutagenesis, and cytoplasmic fusion was carried out (fusogenic agent was polyethylene glycol 4000), subcultured, Realized genome shuffling, optimized and integrated the dominant mutations of all mutagenized progenies of Bacillus natto 10261 and 10623, and bred a high-yield NK and PQQ Natto with high yield, vigorous growth, stable genetics, and suita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com