Rare earth doped nanometer composite ceramic coating and production technology thereof

A rare earth doping and nano-composite technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the problems of low toughness, low bonding strength, limited coating, etc., to achieve improved erosion resistance, The effect of improved corrosion resistance and reliable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

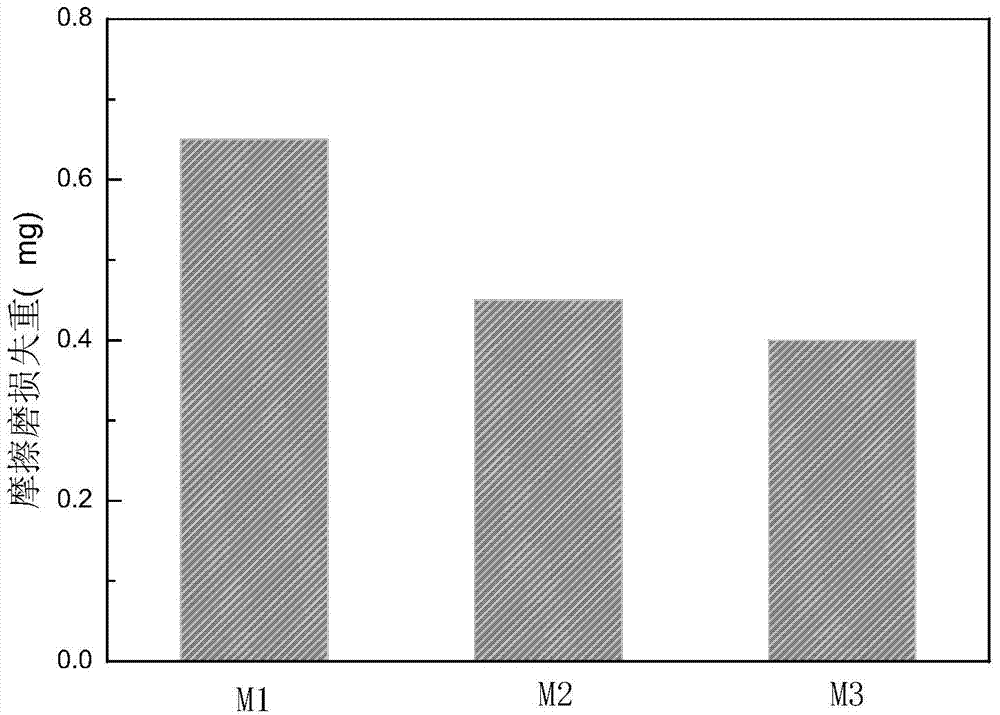

Examples

Embodiment 1

[0030] Nano WC-10Co4Cr powder and Sc 2 o 3 mixed, where Sc 2 o 3 The content is 1wt%, and the powder is mixed evenly by using a three-dimensional powder mixing test machine, the rotation speed is 25RPM, and the mixing frequency is 40,000 times.

[0031] Lay the rare earth-doped nano-tungsten carbide powder flat, put it in an incubator for drying, the drying temperature is 120°C, and the drying time is 2 hours.

[0032] Clean and dry the stainless steel surface with acetone and alcohol, and then sandblast the surface to remove impurities such as surface scale. Sandblasting is carried out in the manner described above.

[0033] Fix the substrate 1 of the spraying operation with a fixture, and use a closed-loop supersonic flame spraying equipment to spray rare earth-doped nano-tungsten carbide powder. The spraying process parameters are: kerosene flow rate 24L / h, oxygen flow rate 54m3 / h, feed rate 80g / min, carrier gas flow rate 10L / min, spraying distance 360mm, get rare eart...

Embodiment 2

[0036] Nano WC-10Co4Cr powder and La 2 o 3 mixed, where La 2 o 3 The content is 1.5wt%, and the powder is mixed evenly with a three-dimensional powder mixing test machine, the rotation speed is 25RPM, and the mixing frequency is 40,000 times.

[0037] Lay the rare earth-doped nano-tungsten carbide powder flat, put it in an incubator for drying, the drying temperature is 100°C, and the drying time is 3 hours.

[0038] Clean the stainless steel surface with acetone and alcohol and dry it. The surface blasting treatment is the same as in Embodiment 1.

[0039] Fix the substrate 1 of the spraying operation with a fixture, and use supersonic flame spraying equipment to spray nano-tungsten carbide powder. The spraying process parameters are: kerosene flow rate 28L / h, oxygen flow rate 52m 3 / h, the delivery rate is 70g / min, the carrier gas flow rate is 10L / min, the spraying distance is 400mm, and the rare earth doped nanocomposite ceramic coating 2 is obtained, see figure 1 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average microhardness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com