Inexpensive non-magnetic stainless steel and manufacturing method thereof

A non-magnetic stainless steel and manufacturing method technology, applied in the field of stainless steel materials, can solve the problems of low alloy cost, high alloy cost, and expensive price, and achieve the effects of low alloy cost, saving nickel resources, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

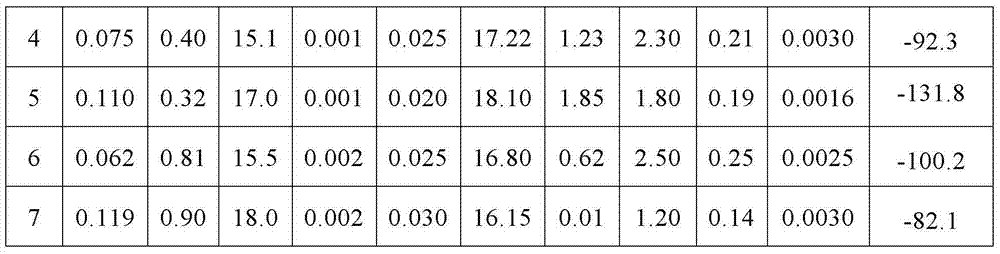

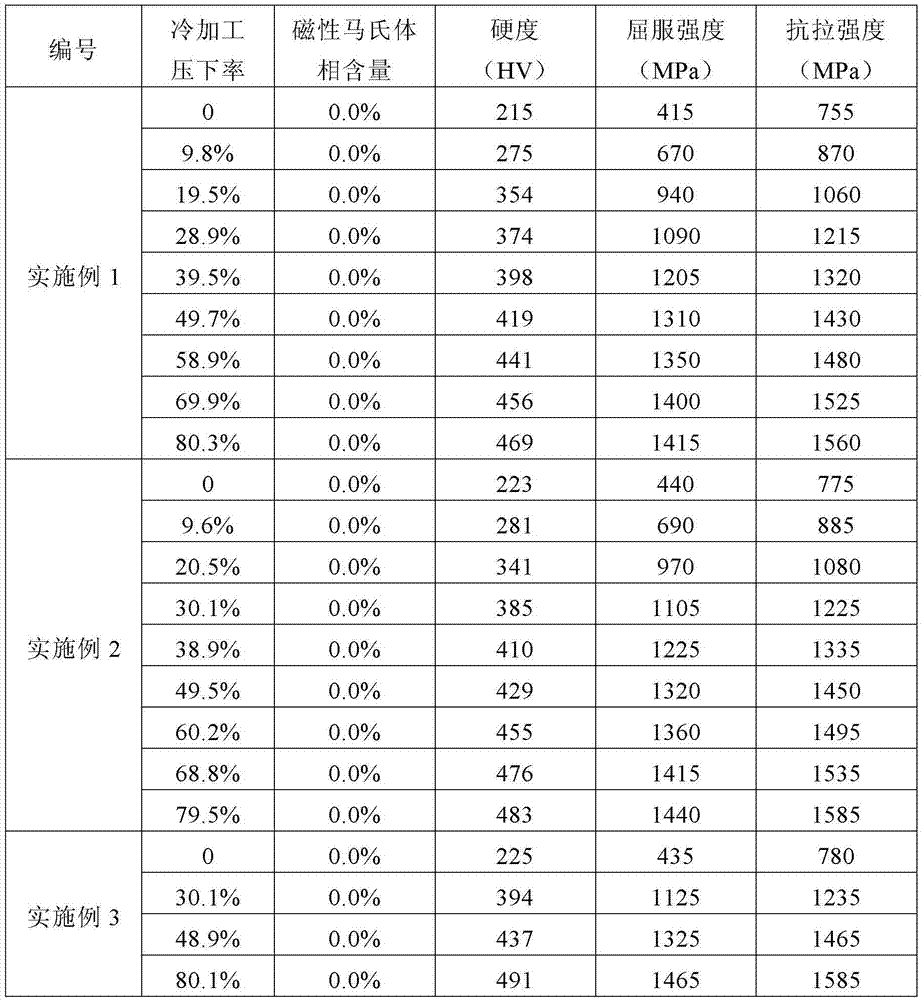

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with embodiment.

[0046] The manufacturing process of the non-magnetic austenitic stainless steel of the present invention is as follows: blast furnace / electric furnace smelting→argon-oxygen decarburization furnace smelting→extra-furnace refining→continuous casting / die casting→hot rolling→hot annealing and pickling→cold rolling or cold forging→cold Unpickling.

[0047] The embodiment of the present invention adopts the two-step method of electric furnace and argon-oxygen decarburization furnace (AOD) for smelting. During the smelting process, raw materials such as low-nickel pig iron, ferrochrome, ferrosilicon, manganese metal, electrolytic copper, and scrap steel are added according to a certain ratio. After the electric furnace is melted, the molten steel is poured into the AOD furnace after melting, and blowing is carried out in the AOD furnace for removing C, removing S, increasing N, and controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com