Small-volume asarin freeze-dried powder injection, preparation method and producing apparatus thereof

A technology of freeze-dried powder injection and small volume, which is applied in the direction of freeze-drying transportation, making drugs into special physical or taking forms, medical formulas, etc., which can solve the problems of increasing filling volume, low product output, and energy consumption. problems such as increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The preparation method of small-volume asarone freeze-dried powder injection,

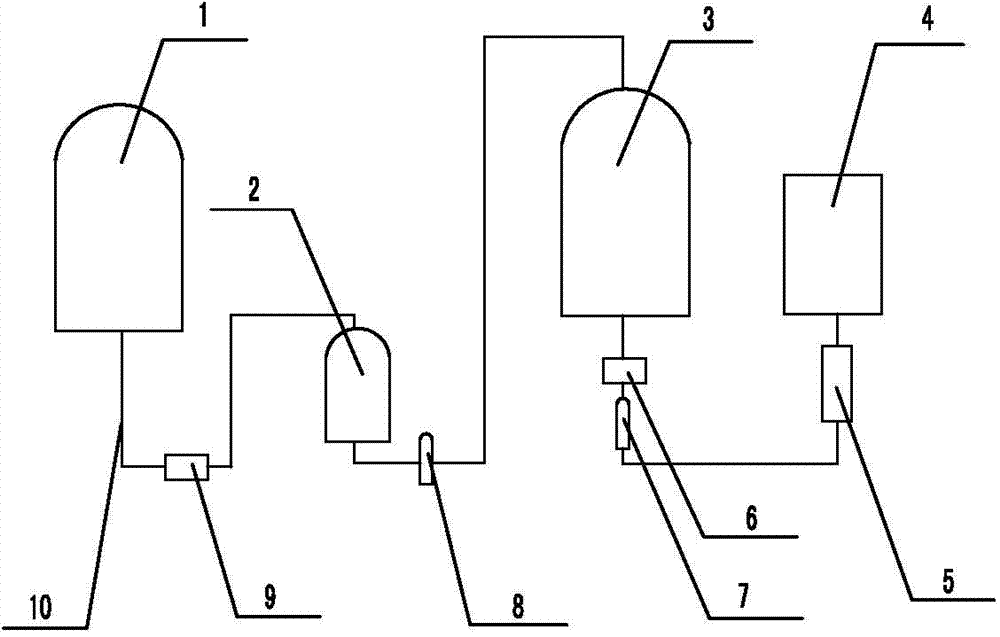

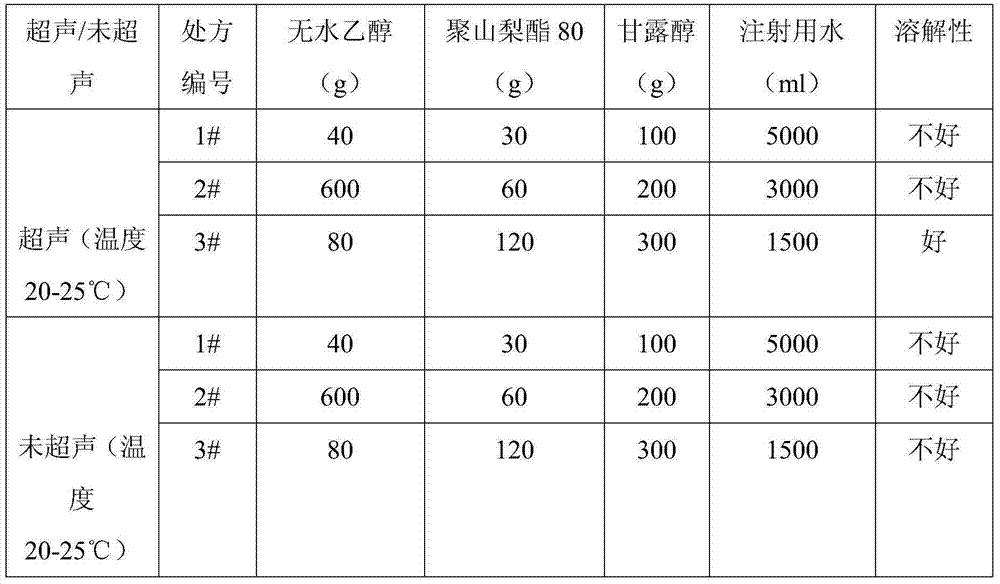

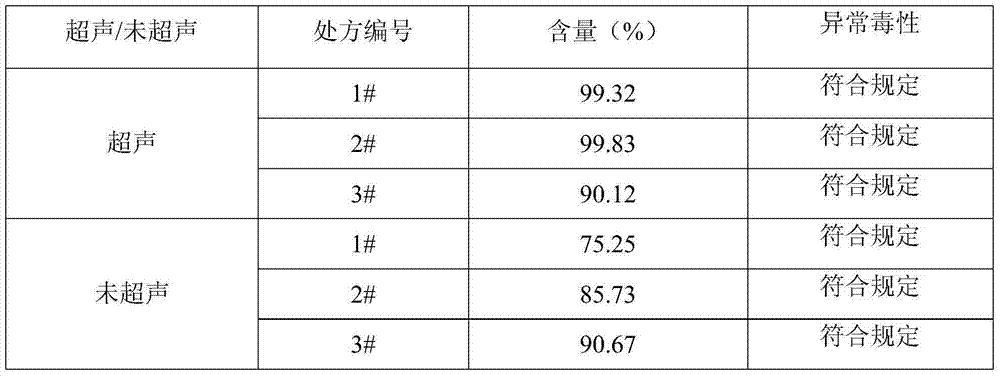

[0026] Mix asarone and absolute ethanol and start stirring, and at the same time, use ultrasonic waves to aid dissolution, and control the temperature at 20°C to 25°C to make a concentrated solution, stir well to dissolve to obtain solution B; at the same time, weigh the prescribed amount of water for injection and add it to keep warm In the preparation tank 1, add mannitol and polysorbate 80, and control the temperature at 20°C to 25°C, until all of them are dissolved to obtain solution A; slowly pour solution B into solution A, and stir evenly. Add activated carbon with a mass concentration of 0.1% for decarbonization for 30 minutes. Turn on the second Grundfos pump 9 and use the titanium rod filter 2 to decarburize and filter the feed liquid through the second sterilizing filter element 8 to sterilize and transport it to the sterile liquid storage tank 3 for storage. After sterilizing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com