Manufacturing method for nitride light emitting diode

A technology of light-emitting diodes and nitrides, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of limited voltage and other electrical properties, affecting growth yield, and disadvantages, and achieves improved electrical uniformity and light extraction efficiency. , The effect of improving the voltage and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

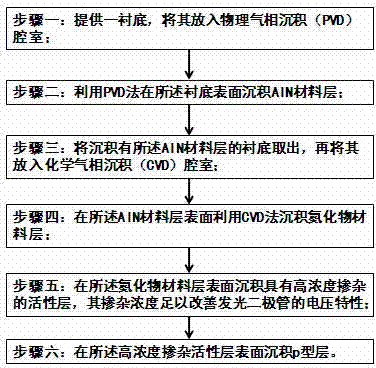

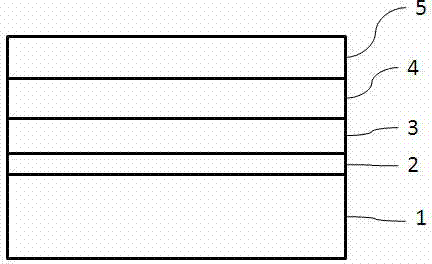

[0036] Please see attached figure 1 and 2 , providing a substrate 1, which is a flat substrate or a patterned substrate, and its material is sapphire, silicon, silicon carbide, gallium nitride or gallium arsenide, etc., wherein the vertical height range of the graphics in the patterned substrate is 2 ~20 microns, the pattern can be formed by dry etching or wet etching; put this large-depth substrate 1 into a PVD chamber, adjust the temperature of the chamber to 350-550°C, and the pressure to 2-10mtorr, using PVD The method deposits an AlN material layer 2 with a flat surface and a thickness of 5 to 350 angstroms on the surface of the substrate 1; due to the film-forming characteristics of the PVD method, when the pattern depth of the patterned substrate is higher than the depth of the conventional substrate, the AlN material layer 2 can still maintain the characteristics of smooth surface and good film quality; then take out the substrate deposited with AlN material layer 2, ...

Embodiment 2

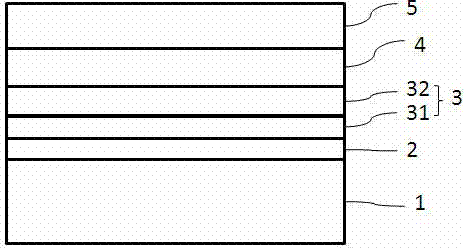

[0038] Please see attached image 3, providing a substrate 1, which is a flat substrate or a patterned substrate, and its material can be sapphire, silicon, silicon carbide, gallium nitride or gallium arsenide, etc.; when a patterned substrate is selected, the vertical height of the pattern The range is 2-20 microns, and its pattern is formed by dry etching or wet etching; put this large-depth substrate 1 into a PVD chamber, adjust the chamber temperature to 350-550°C, and the pressure to 2-10mtorr. The method deposits an AlN material layer 2 with a flat surface and a thickness of 5 to 350 angstroms on the surface of the substrate 1; due to the film-forming characteristics of the PVD method, when the pattern depth of the substrate used is higher than that of a conventional patterned substrate, the AlN material layer 2 can still maintain the characteristics of smooth surface and good film quality; then take out the substrate deposited with AlN material layer 2, put it into the ...

Embodiment 3

[0040] Please see attached Figure 4 , this embodiment is optimized on the basis of Embodiment 2, that is, when the substrate deposited with the AlN material layer 2 is taken out and put into the chemical vapor deposition (CVD) chamber, the temperature of the chamber is adjusted to 200 -900°C, on the surface of the AlN material layer 2, first deposit a low-temperature gallium nitride layer 30 with a thickness of 5 angstroms to 1500 angstroms, and then raise the chamber temperature to above 900°C to deposit a high-temperature non-doped gallium nitride layer 31, Then deposit the n-type gallium nitride layer 32 , and finally adjust the temperature of the chamber to continue depositing the doped active layer 4 and the p-type layer 5 .

[0041] In this embodiment, the low-temperature gallium nitride layer 30 is first deposited on the AlN material layer, and then the low-temperature gallium nitride layer 30 is subjected to an elevated temperature annealing treatment before the high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com