A kind of ceramic material with high electrical energy storage efficiency and preparation method thereof

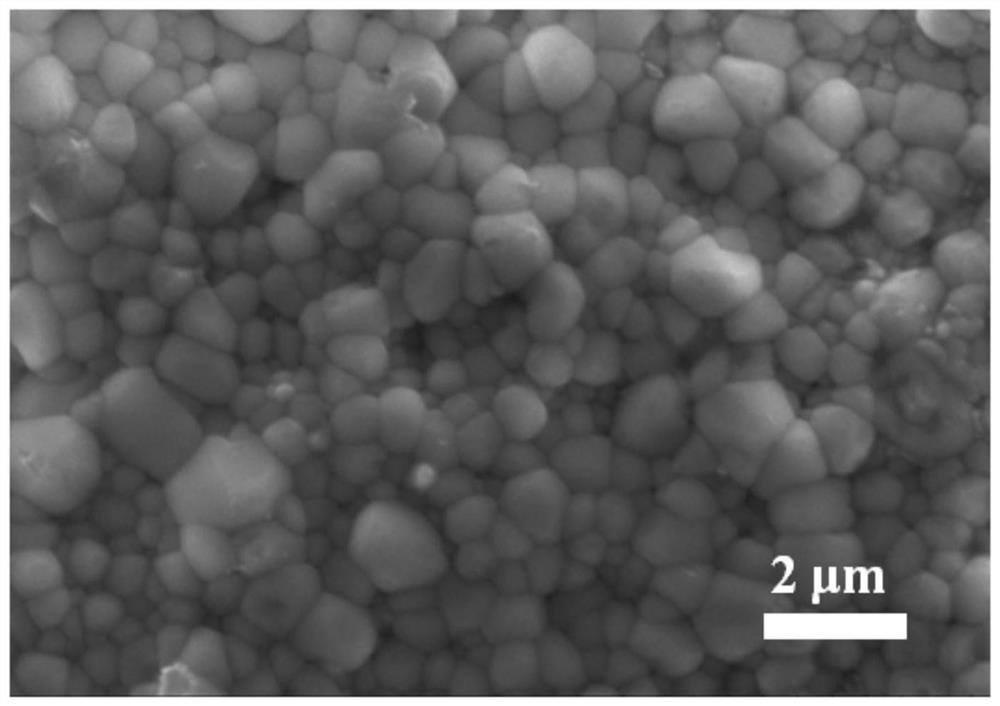

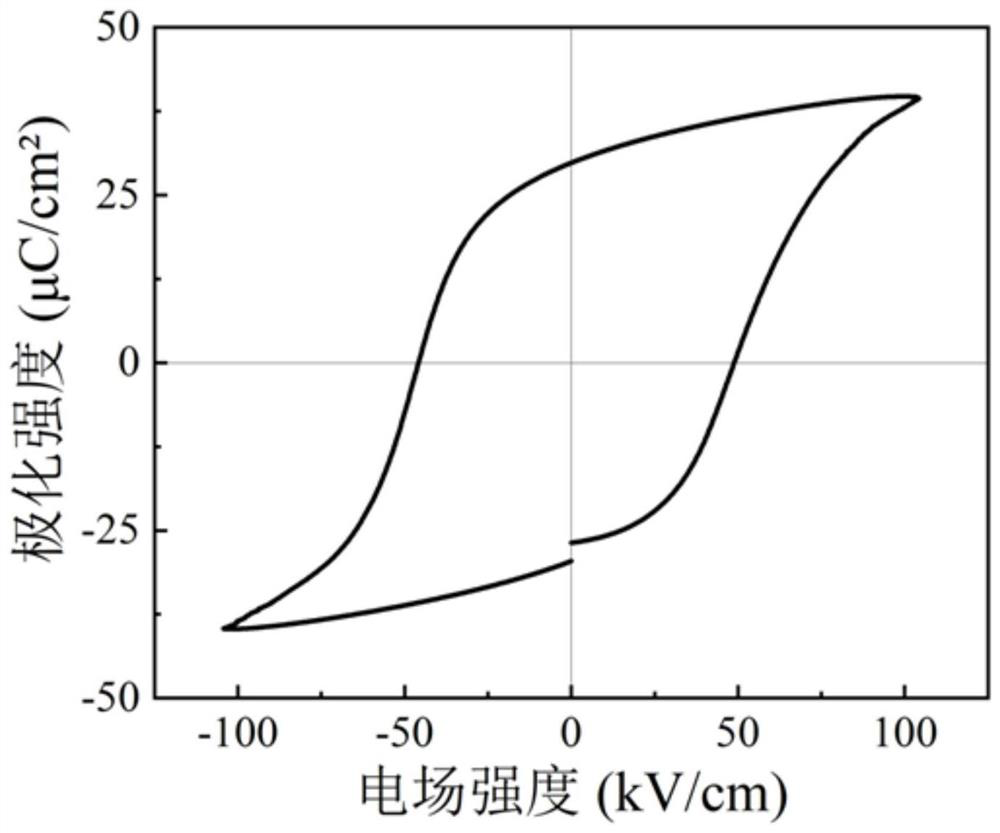

An electric energy storage and ceramic material technology, applied in the field of functional ceramic materials, can solve the problems of large electrostrictive effect, high cost and high price, and achieve the effects of improved electric energy storage efficiency, high stability and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

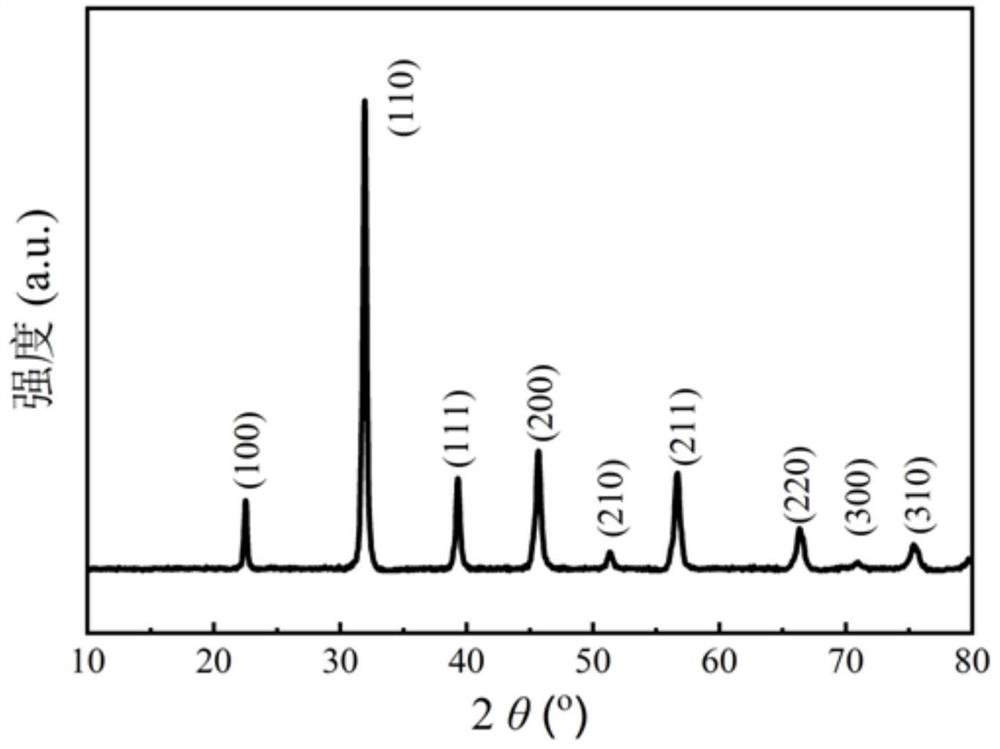

[0025] The invention relates to a ceramic material with high electric energy storage efficiency and a preparation method thereof. The chemical composition of the formula is (1-x)((1-y)BaTiO 3 -y(Bi 0.5 Na 0.5 )TiO 3 )-xSr(Sc 0.5 Nb 0.5 )O 3 , prepared by solid-state sintering method.

[0026] The method of the present invention comprises the following steps:

[0027] 1. Weigh raw materials

[0028] According to (1-x)((1-y)BaTiO 3 -y(Bi 0.5 Na 0.5 )TiO 3 )-xSr(Sc 0.5 Nb 0.5 )O 3 Calculate the stoichiometric ratio of the chemical composition, and weigh the high-purity Bi 2 o 3 、Na 2 CO 3 、BaCO 3 , SrCO 3 、Sc 2 o 3 、TiO 2 and Nb 2 o 5 raw powder.

[0030] Put the mixed powder of raw materials in a ball mill jar, add absolute ethanol, ball mill on a planetary ball mill for 24 h, then take it out, and put it in a dry box for 80 o C drying.

[0031] 3. Pre-sintering:

[0032] Put the powder dried by the ball mill into a high...

Embodiment 1

[0039] Set the chemical composition to 0.90 (0.65BaTiO 3 -0.35 (Bi 0.5 Na 0.5 )TiO 3 ) -0.10Sr(Sc 0.5 Nb 0.5 )O 3 According to the formula of energy storage ceramics, high-purity raw materials were weighed according to the stoichiometric ratio, anhydrous ethanol was added, ball milled in a planetary ball mill for 24 h, and then dried to obtain a mixture. The mixture is then placed in a sintering furnace for sintering at 900 o Pre-sintered at C for 2 h, cooled naturally; after the pre-sintered ceramic powder was milled into powder twice, 7 wt% polyvinyl alcohol solution was added, mixed evenly in a mortar, and then pressed into a diameter of 12 mm by molding. A disc with a thickness of 1.5 mm. Place the pressed disc in a sintering furnace for sintering at 600 o C heat preservation 4 hours debinding, with 3 o The heating rate of C / min increases the temperature to 1170 o C sintering, heat preservation 4 h. After sintering, it is naturally cooled to room temperature wit...

Embodiment 2

[0042] Change the chemical composition to 0.65BaTiO 3 -0.35 (Bi 0.5 Na 0.5 )TiO 3 Weigh the high-purity raw materials according to the stoichiometric ratio, add absolute ethanol, ball mill in a planetary ball mill for 24 h, and dry to obtain the mixture. The mixture is then placed in a sintering furnace for sintering at 900 o Pre-sintered at C for 2 h, cooled naturally; after the pre-sintered ceramic powder was milled into powder twice, 7 wt% polyvinyl alcohol solution was added, mixed evenly in a mortar, and then pressed into a diameter of 12 mm by molding. A disc with a thickness of 1.5 mm. Place the pressed disc in a sintering furnace for sintering at 600 o C heat preservation 4 hours debinding, with 3 o The heating rate of C / min increases the temperature to 1160 o C sintering, heat preservation 4 h. After sintering, it is naturally cooled to room temperature with the furnace to obtain energy storage ceramics.

[0043] Using the Agilent ferroelectric analyzer to me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com