Method for enriching niobium by high-temperature roasting and low-intensity magnetic separation

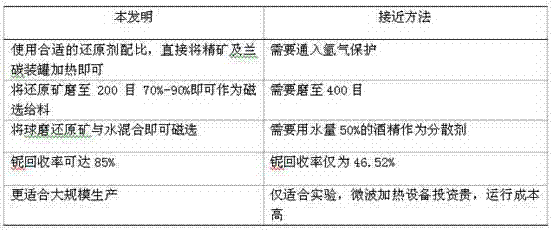

A technology of high-temperature roasting and weak magnetic separation, applied in chemical instruments and methods, magnetic separation, solid separation, etc., to achieve the effects of simple equipment, reduced emissions, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

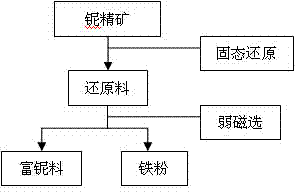

Method used

Image

Examples

example

[0025] The niobium concentrate is gradually processed under the process conditions given in the "high-temperature roasting-weak magnetic separation" method.

[0026] The niobium concentrate in this example comes from the niobium concentrate selected in the "Baiyun Obo Tailings Comprehensive Utilization" project.

[0027] Table 1 shows the multi-element analysis of niobium concentrate (mass percentage)

[0028]

[0029] Using the solid-state reduction method, the coke is mixed with 90% of the total amount of minerals. The TFe content in the niobium concentrate is 43.5%, Nb 2 O 5 The content is 5.75%, heated in a muffle furnace, the heating time is calculated according to the quality of the mineral, is 10min / g, the temperature is 1200℃, and the TFe content is 51.06%, Nb after roasting 2 O 5 Reduced niobium concentrate with a content of 6.74%.

[0030] The reduced niobium concentrate is ground to a 200-mesh content of 70%, and magnetically separated in a weak magnetic tube with a magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com