Single-layer graphene dispersion liquid and preparation method thereof

A single-layer graphene and dispersion technology, applied in the field of single-layer graphene dispersion and its preparation, can solve problems such as difficulty in dispersing single-layer graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of this a kind of monolayer graphene dispersion liquid comprises:

[0027] Step 1, graphite is prepared into secondary expanded graphite;

[0028] Step 2, mixing the secondary expanded graphite and the dispersant in a mass ratio of 5:1 to 1:5 to obtain a mixed dispersion system;

[0029]Step 3, performing mechanical shear peeling on the mixed dispersion system;

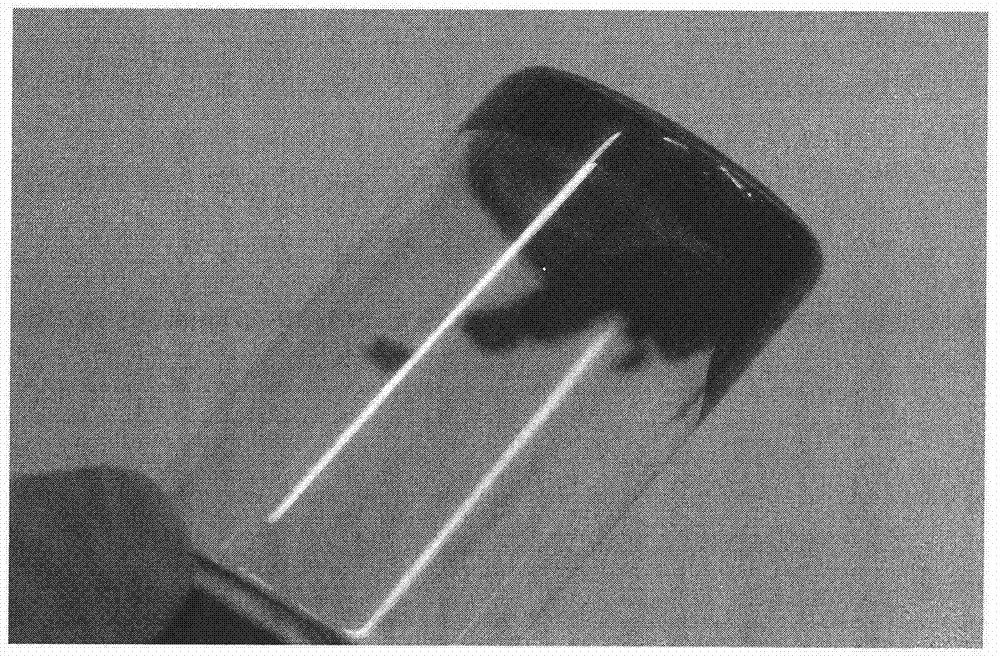

[0030] Step 4, obtaining a monolayer graphene dispersion.

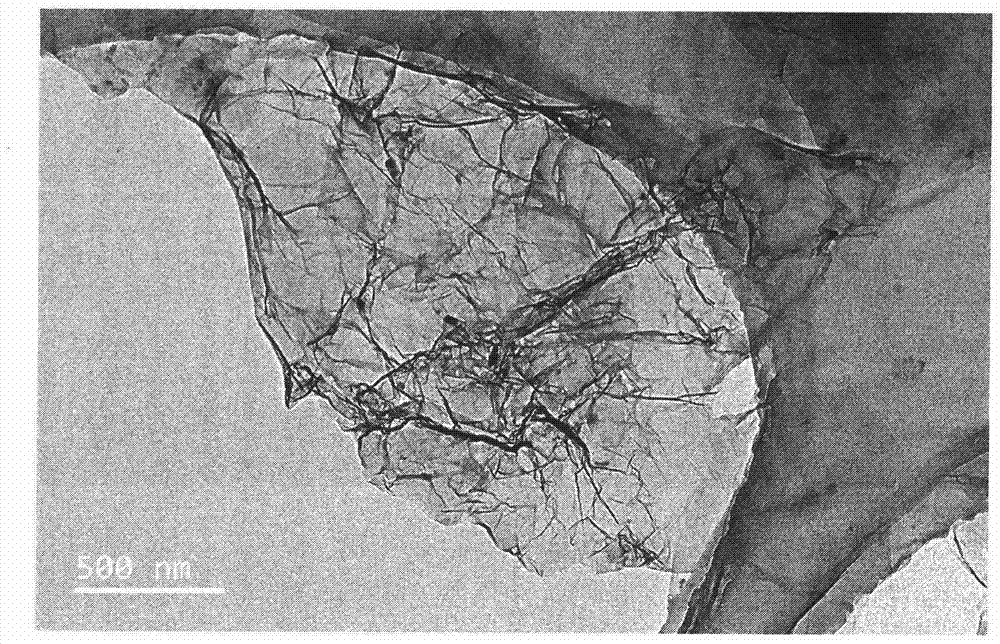

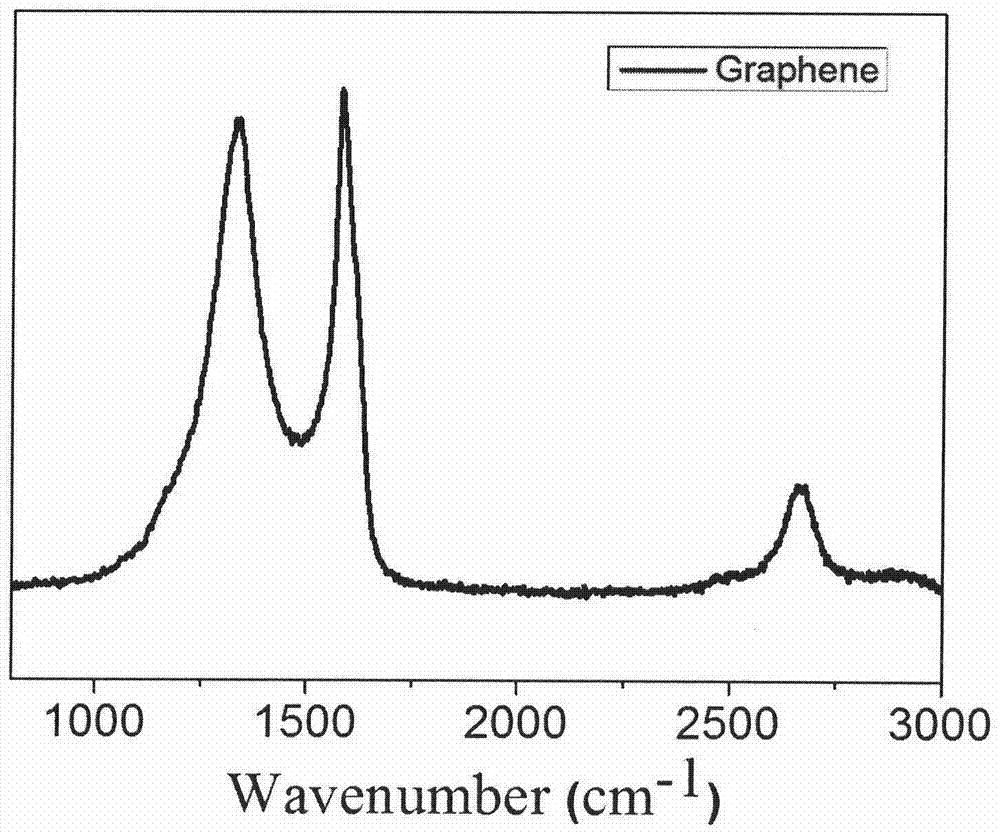

[0031] The single-layer graphene dispersion prepared by the preparation method of the above-mentioned single-layer graphene dispersion comprises: 1-10wt% graphene, 0.01-5wt% dispersant; the concentration of the graphene dispersion is 10-60 mg mL -1 The diameter of graphene is 200 nanometers to 10 microns; the dispersant is sodium dodecylbenzenesulfonate, sodium dodecylsulfonate, polyvinylpyrrolidone, sodium cholate, polystyrene, hexadecyl trimethyl One or more ammonium bromide.

[0032] In this embodiment, graphite is first p...

Embodiment 1

[0036] Preparation of secondary expanded graphite: Put 5g of graphite in a 500mL three-necked flask, immerse the three-necked flask in the ice-water mixture, then add 45mL of concentrated nitric acid and 87.5mL of concentrated sulfuric acid, and slowly add 55g of potassium chlorate into the three-necked flask (At least add more than 15 minutes. Note: chlorine dioxide will be produced when adding potassium chlorate, and it will explode when the concentration is high). This process is stirred for 72 hours, and the treated graphite is washed into neutral with a large amount of water, and obtained after drying. powder; then, the oxidized graphite is subjected to high-temperature reduction at 1000-1300°C for an expansion time of 30 seconds to 5 minutes in a tube furnace to obtain primary expanded graphite. 1500 ℃ high temperature reduction expansion to obtain secondary expanded graphite.

[0037] Preparation of single-layer graphene dispersion: mix secondary expanded graphite and p...

Embodiment 2

[0042] Preparation of secondary expanded graphite: Put 5g of graphite in a 500mL three-necked flask, immerse the three-necked flask in the ice-water mixture, then add 50mL of concentrated nitric acid and 98mL of hydrogen peroxide, and slowly add 45g of potassium chlorate to the three-necked flask (at least Add more than 15min.Attention: can produce chlorine dioxide when potassium chlorate is added, can produce explosion when concentration is high), this process stirs and handles 72h, the graphite that handles is washed into neutrality with a large amount of water, obtains powder after drying; The oxidized graphite is in the tube furnace, the expansion time is 30S~5min, and the temperature is 1300~1500℃, and the high temperature reduction is carried out to obtain the primary expanded graphite. After the primary expanded graphite is treated by the same method as above, it is reduced and expanded at a high temperature of 800~1800℃. Obtain secondary expanded graphite.

[0043] Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com