A kind of dense ceramic oxygen permeable membrane with high stability and high permeability and preparation method thereof

A high-permeability, high-stability technology, applied in separation methods, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the long-term stability of oxygen-permeable membranes, chemical stability, mechanical strength and thermal shock resistance, high oxygen The permeation flux cannot be combined at the same time to achieve the effect of improving chemical stability, high mechanical strength, and avoiding corrosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

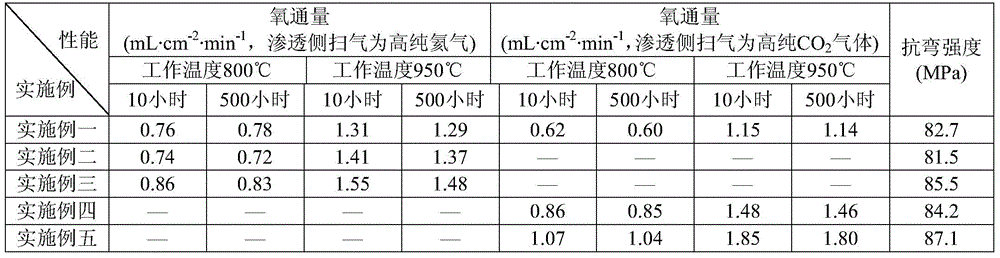

Examples

Embodiment 1

[0037] 1. In this embodiment, a dense ceramic oxygen-permeable membrane with high stability and high permeability is a tubular Ce 0.8 SM 0.2 o 2-δ -Sm 0.6 Sr 0.4 Fe 0.7 Cu 0.3 o 3-δ Two-phase dense ceramic oxygen-permeable membrane whose oxygen ion conductor phase is Ce 0.8 SM 0.2 o 2-δ Porous matrix, ion-electronic mixed conductor phase is Sm 0.6 Sr 0.4 Fe 0.7 Cu 0.3 o 3-δ , and located in the connected pores in the matrix; according to the volume percentage, the oxygen ion conductor phase is 85.4%, and the ion-electronic mixed conductor phase is 14.6%.

[0038] 2. The above-mentioned tubular Ce in this embodiment 0.8 SM 0.2 o 2-δ -Sm 0.6 Sr 0.4 Fe 0.7 Cu 0.3 o 3-δ The preparation method of dense ceramic oxygen-permeable membrane, its steps are as follows:

[0039] (1) Preparation of raw material powder

[0040] (1-1)Ce 0.8 SM 0.2 o 2-δ Preparation of Oxygen Ion Conductor Phase Powder

[0041] Using the co-precipitation method, first dissolve the co...

Embodiment 2

[0051] 1. In this embodiment, a dense ceramic oxygen-permeable membrane with high stability and high permeability is a tubular Ce 0.8 Gd 0.2 o 2-δ -Gd 0.6 Sr 0.4 Fe 0.75 Cu 0.25 o 3-δ Two-phase dense ceramic oxygen-permeable membrane whose oxygen ion conductor phase is Ce 0.8 Gd 0.2 o 2-δ Porous matrix, ion-electronic mixed conductor phase is Gd 0.6 Sr 0.4 Fe 0.75 Cu 0.25 o 3-δ , and located in the connected pores in the matrix; according to the volume percentage, the oxygen ion conductor phase is 85.7%, and the ion-electronic mixed conductor phase is 14.3%.

[0052] 2. The above-mentioned tubular Ce in this embodiment 0.8 Gd 0.2 o 2-δ -Gd 0.6 Sr 0.4 Fe 0.75 Cu 0.25 o 3-δ The preparation method of dense ceramic oxygen-permeable membrane, take corresponding metal nitrate as raw material, its technological parameter is the same as embodiment one, the tubular Ce that step (2) makes 0.8 Gd 0.2 o 2-δ The through-porosity of the oxygen ion conductor phase mat...

Embodiment 3

[0054] 1. In this embodiment, a high-stability and high-permeability dense ceramic oxygen-permeable membrane is a sheet-like Ce 0.8 Gd 0.2 o 2-δ -Gd 0.6 Sr 0.4 Fe 0.75 Cu 0.25 o 3-δ Two-phase dense ceramic oxygen-permeable membrane whose oxygen ion conductor phase is Ce 0.8 Gd 0.2 o 2-δ Porous matrix, ion-electronic mixed conductor phase is Gd 0.6 Sr 0.4 Fe 0.75 Cu 0.25 o 3-δ , and located in the connected pores in the matrix; according to the volume percentage, the oxygen ion conductor phase is 87.5%, and the ion-electronic mixed conductor phase is 12.5%.

[0055] 2. The above-mentioned flaky Ce in this embodiment 0.8 Gd 0.2 o 2-δ -Gd 0.6 Sr 0.4 Fe 0.75 Cu 0.25 o 3-δ The preparation method of dense ceramic oxygen-permeable membrane, its steps are as follows:

[0056] (1) Preparation of raw material powder

[0057] Using the corresponding metal nitrates as raw materials, Ce 0.8 Gd 0.2 o 2-δ Oxygen ion conductor phase powder and Gd 0.6 Sr 0.4 Fe 0.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com