High-expansion-ratio ice cream without food additive and preparation method thereof

A food additive and high expansion rate technology, applied in frozen sweets, food science, applications, etc., can solve the problems of improper materials, abuse, unknown sources, etc., achieve high coldness, simple method, and good emulsification effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

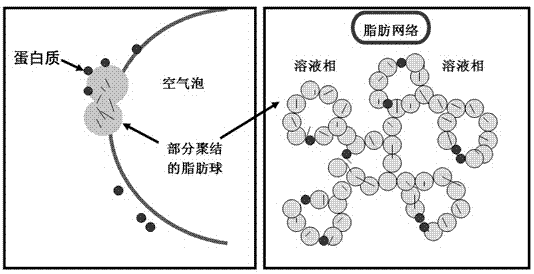

Method used

Image

Examples

Embodiment 1

[0025] The present embodiment prepares the ice cream of the high expansion ratio not containing food additives according to the following steps:

[0026] 1. Prepare emulsified liquid phase A according to the following mass fraction ratio: 20% anhydrous butter, 0.4% whey protein powder, and water as the balance, and homogenize three times under high-pressure homogenization at 50 MPa.

[0027] 2. Prepare solution phase B according to the following mass fraction ratio: 20% skimmed milk powder, 3% soybean protein powder, 24% white granulated sugar, and the balance is water. Dissolve skimmed milk powder and soybean protein powder in water, and put Heat for 10 minutes, and when the temperature drops to about 60°C, add white granulated sugar to dissolve it completely to make solution phase B.

[0028] 3. The prepared two phases were sterilized in a water bath at 65°C for 30 minutes; the sterilized emulsion was aged at 4°C overnight.

[0029] 4. Mix emulsified liquid phase A and solu...

Embodiment 2

[0032] The difference between this embodiment and Example 1 is: the fat in step one is palm oil, the mass fraction of palm oil is 25%, the whey protein powder is 0.6%, the homogenizing pressure is 60 MPa, and the mass fraction of skimmed milk powder in step two The fraction is 18%, soybean protein powder 3.5%, and white sugar 26%.

[0033] The ice cream with high expansion rate without food additives produced in this example has good melting resistance, the melting rate is 36% after 90 minutes, the average particle size of fat globules is ≤3 μm, and the expansion rate is 70%. Ice cream is yellowish in color, fine in texture, good in shape, soft in shape, good in taste and flavor, moderate in hardness, and without obvious crystallization.

Embodiment 3

[0035]The differences between this example and Example 1 are: the mass fraction of anhydrous butter in step 1 is 30%, the whey protein powder is 0.8%, and the homogenization pressure is 70 MPa; the mass fraction of skimmed milk powder in step 2 is 17%, 4% soybean protein powder, 28% white sugar. In step 4, the emulsified liquid phase A and the solution phase B are mixed according to the mass ratio of 1:2.

[0036] The ice cream with high expansion rate without food additives produced in this example has enhanced resistance to melting. After 90 minutes, the melting rate is 32%, the average particle size of fat globules is about 4 μm, and the expansion rate is 67%. Ice cream is yellowish in color, smooth in texture, good in shape, low in coldness, good in taste and flavor, moderate in hardness, and without obvious crystallization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com