High-silicon aluminum alloy cylinder sleeve and preparation method thereof

A high-silicon aluminum alloy and cylinder liner technology, which is applied in the direction of cylinders, cylinder heads, mechanical equipment, etc., can solve the problems of complex process, long process, high cost, etc., and achieve the goal of improving strength and elongation, eliminating stress, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

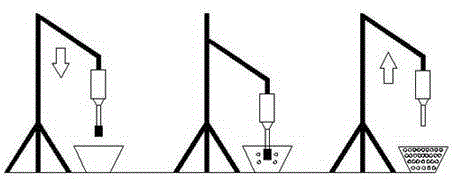

Method used

Image

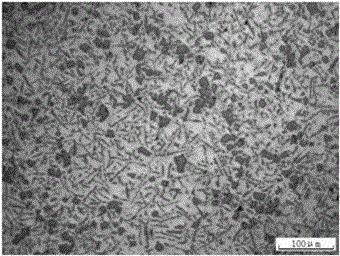

Examples

Embodiment 1

[0030] A high-silicon aluminum alloy cylinder liner, its preparation method specifically comprises the following steps:

[0031] 1) Ingredients: mix pure aluminum, pure magnesium, aluminum magnesium, industrial crystalline silicon, aluminum manganese, aluminum rare earth, Al-Ti-C-RE, phosphor copper or sulfur according to the amount of alloying elements required; And the weight percentage of each element is: Si 25%, Mg 1.2%, Ti 1.5%, Mn 1.0%, P 0.05%, RE 2.5%, Fe 0.3%, C 0.2%, and the balance Al;

[0032] 2) Melting: The alloy ingot composed of pure aluminum with high melting point, industrial crystalline silicon, aluminum manganese, aluminum rare earth and sulfur is covered with a layer of protective flux mixed with NaCl and KCl to prevent oxidation and the amount of protective flux The alloy ingot is 2% of the weight of the alloy ingot; then the alloy ingot is added to the electric furnace for melting, and then the temperature of the melted aluminum liquid is adjusted to 820...

Embodiment 2

[0039] A high-silicon aluminum alloy cylinder liner, its preparation method specifically comprises the following steps:

[0040] 1) Ingredients: mix pure aluminum, pure magnesium, aluminum magnesium, industrial crystalline silicon, aluminum manganese, aluminum rare earth, Al-Ti-C-RE, phosphor copper or sulfur according to the amount of alloying elements required; And the weight percentage of each element is: Si 17%, Mg 0.5%, Ti 0.3%, Mn 1%, P 0.03%, RE 0.3%, Fe 0.3%, C 0.02%, and the balance is Al;

[0041] 2) Melting: Cover the alloy ingot composed of pure aluminum with high melting point, industrial crystalline silicon, aluminum manganese, aluminum rare earth and sulfur with a layer of protective flux mixed with KCl and NaF to prevent oxidation. The amount of protective flux is 3% of the weight of the alloy ingot; then put the alloy ingot into the electric furnace for smelting, then adjust the temperature of the melted aluminum to 800°C, press the low melting point aluminum ...

Embodiment 3

[0048] A high-silicon aluminum alloy cylinder liner, its preparation method specifically comprises the following steps:

[0049] 1) Ingredients: mix pure aluminum, pure magnesium, aluminum magnesium, industrial crystalline silicon, aluminum manganese, aluminum rare earth, Al-Ti-C-RE, phosphor copper or sulfur according to the amount of alloying elements required; And the weight percentage of each element is: Si 35%, Mg 5%, Ti 1.5%, Mn 2%, S 0.3%, RE 2.5%, Fe 0.6%, C 0.3%, and the balance is Al;

[0050] 2) Melting: Cover a layer of NaCl, KCl and NaSiF on the alloy ingot composed of pure aluminum with high melting point, industrial crystalline silicon, aluminum manganese, aluminum rare earth and sulfur 6 The protective flux made by mixing is used to prevent oxidation. The amount of protective flux is 1% of the weight of the alloy ingot; then the alloy ingot is added to the electric furnace for melting, and then the temperature of the molten aluminum after melting is adjusted to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com