Novel preparation method of waxberry wine

A technology for fresh and frozen bayberry, applied in the field of berry processing, can solve the problems of uneven quality of bayberry wine, limited processing capacity, insufficient flavor, etc., and achieves the effects of good flavor, short production cycle, and improved nutrition and flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

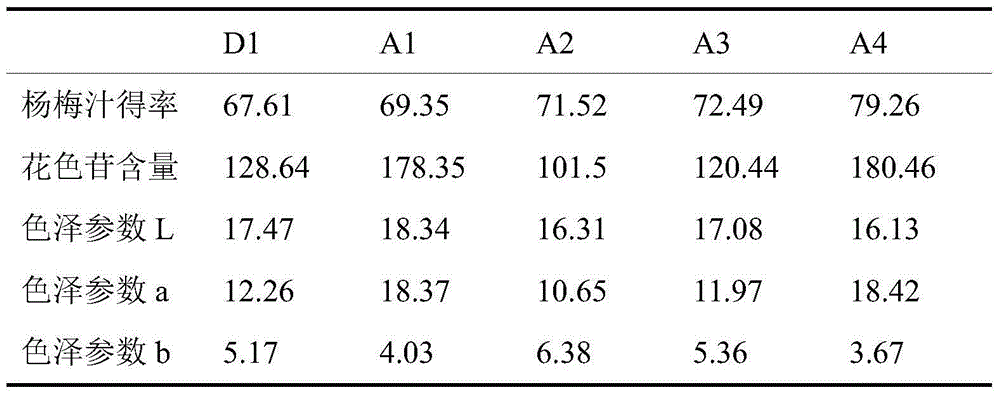

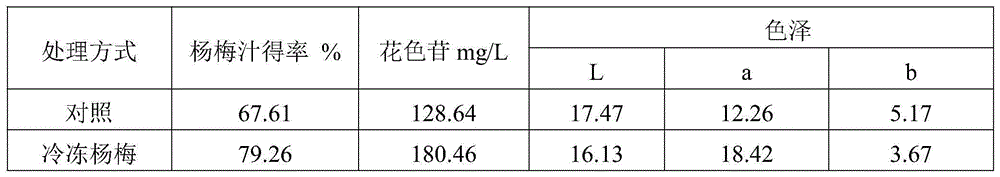

[0036] Example 1 Effects of frozen beating, infrared radiation, and high-pressure homogenization on the quality of bayberry juice

[0037] Frozen red bayberry is processed respectively according to the following methods:

[0038] D1: (i.e. Control 1), the method for obtaining red bayberry juice according to the conventional method, that is, washing fresh red bayberry, removing the core, beating, and filtering to obtain the original red bayberry juice.

[0039] A1: Freezing and beating, that is, washing fresh red bayberries, removing cores, blanching in boiling water, quick freezing in a fluidized bed to obtain frozen red bayberries, freezing and beating, and filtering to obtain raw bayberry juice.

[0040] A2: Infrared irradiation, that is, washing fresh red bayberry, removing cores, beating, infrared irradiation, and filtering to obtain raw red bayberry juice.

[0041] A3: High-pressure homogenization, that is, fresh red bayberry is washed, pitted, beaten, high-pressure homo...

Embodiment 2

[0049] Embodiment 2 produces red bayberry fermented wine according to the following steps

[0050] 5kg of fresh red bayberry has been de-nucleated, blanched in boiling water at 100°C for 3 minutes, cooled by rapid wind to room temperature, and quick-frozen in a fluidized bed at an air temperature of -40°C, with a vertical upward wind speed of 8m / s, quick-frozen for 8 minutes, and wrapped in a polyethylene plastic bag Packaged and stored frozen at -20°C.

[0051] Take 1 kg of the above-mentioned frozen red bayberry, directly freeze and beat, infrared radiation, and high-pressure homogenization, and use infrared radiation technology to process the raw bayberry pulp obtained through cold beating. The conditions are: power 150-300W, irradiation distance 200mm, wavelength range 3 -50um, time 12min, to promote the dissolution of flavor substances and nutrients; homogenization conditions: pressure 22MPa, temperature 55°C, filter to obtain 765g red bayberry turbid juice. The yield of...

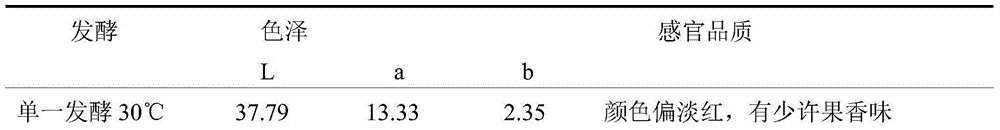

Embodiment 3

[0054] Embodiment 3 produces red bayberry fermented wine according to the following steps

[0055] Take 1kg of frozen bayberry, directly freeze and beat, infrared radiation, high-pressure homogenization, and use infrared radiation technology to process the raw bayberry puree obtained by cold beating. The conditions are: power 150-300W, irradiation distance 100mm, wavelength range 3-50um , time 15min, homogenization conditions: pressure 20MPa, temperature 60°C, filter to obtain 776g red bayberry turbid juice. The yield of the obtained bayberry juice is 79.1%, and the anthocyanin content is 174 mg / L.

[0056] Add potassium metabisulfite in red bayberry juice, make SO in the red bayberry juice Concentration is 70mg / L; Add a certain amount of sucrose in red bayberry juice, control total sugar content at 22%, add a certain amount of potassium sodium tartrate (1.8g / L L) and potassium carbonate (0.8g / L), adjust the pH to 3.5, heat at 100°C for 5min, and cool.

[0057] Rehydrate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com