Method for preparing magnetic molecularly-imprinted adsorbent

A technology of magnetic molecular imprinting and adsorbent, which is applied in the field of environmental protection functional material preparation, can solve the problems of non-reusable raw materials, expensive and difficult to obtain, difficult separation of adsorbent, etc., achieve good adsorption and separation performance, reduce chemical toxicity, and stability Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

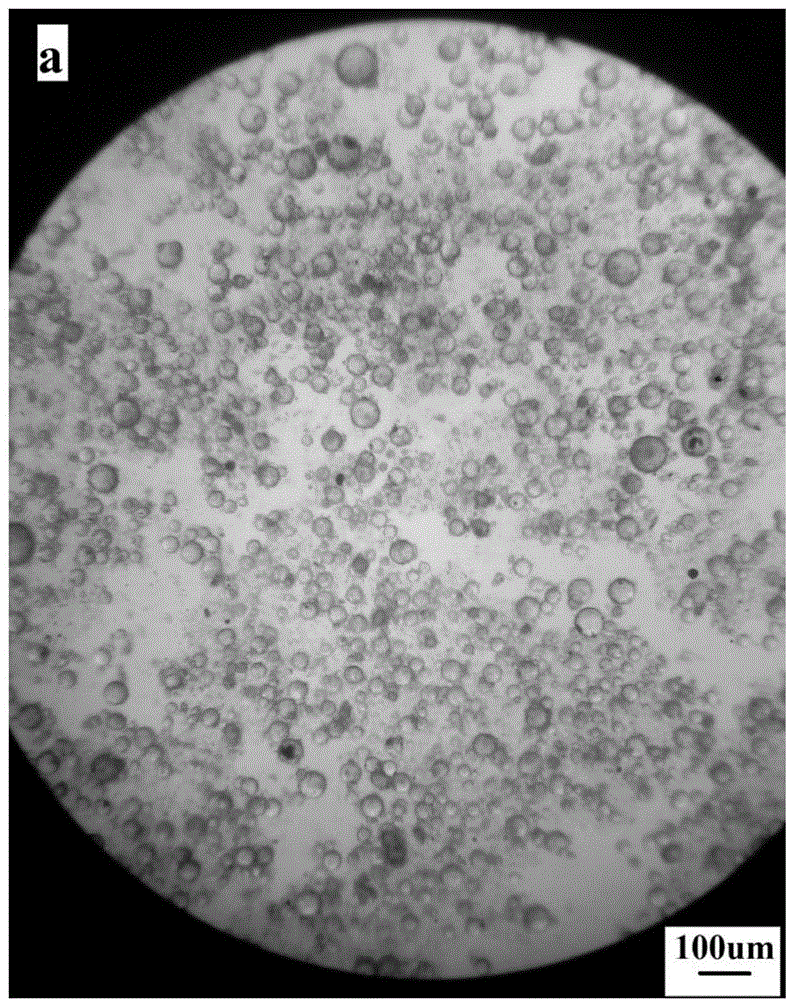

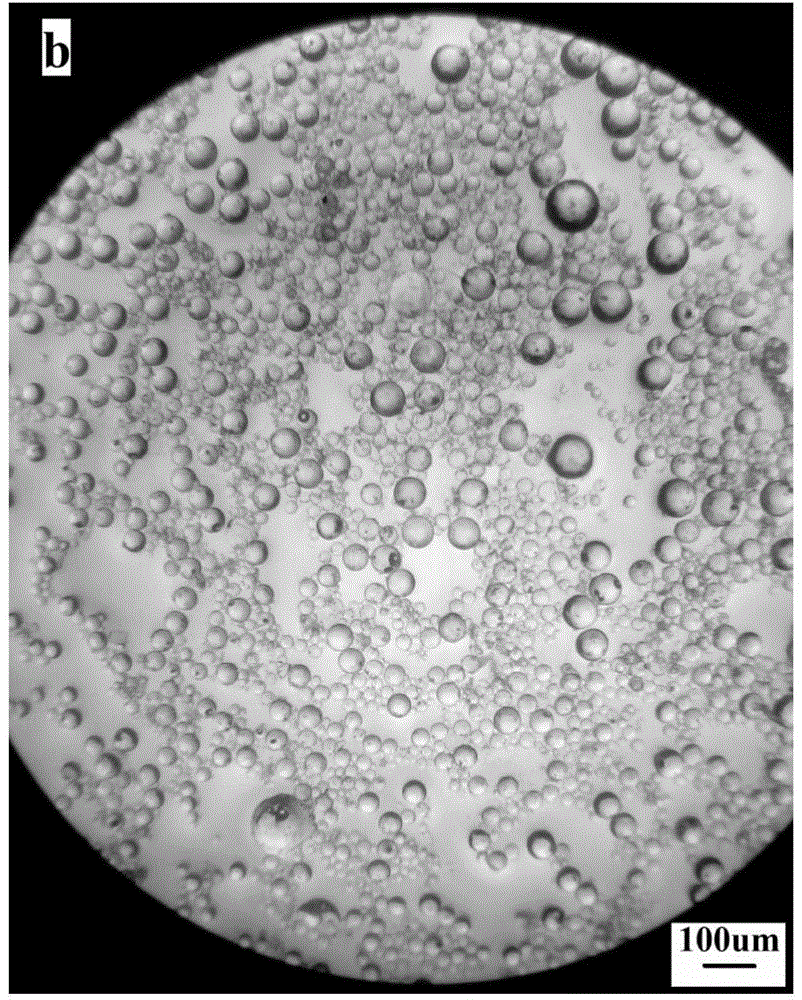

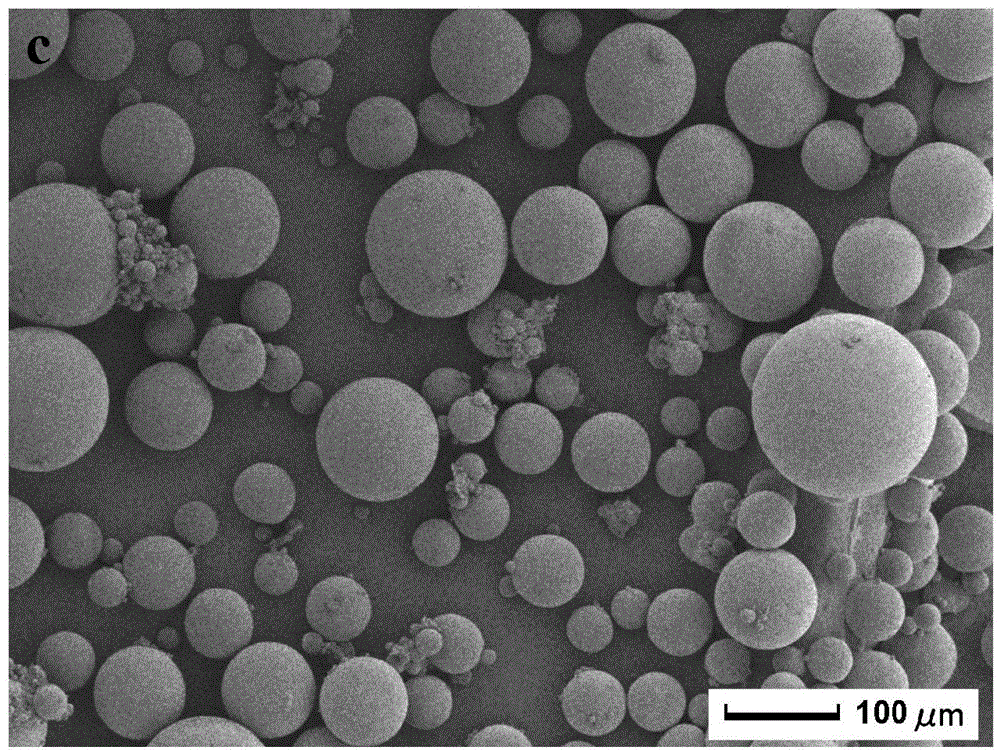

Image

Examples

Embodiment 1

[0030] 1. A method for preparing a magnetic molecular imprinting adsorbent by Pickering emulsion polymerization, characterized in that it is carried out according to the following steps:

[0031] (1) Preparation of chitosan nanoparticles

[0032] First, 0.15 g of acetic acid was added dropwise to 100 mL of distilled water. Then add 0.1 g of chitosan into the weak acid solution with a pH value of about 4.2 and keep stirring. The resulting solution was filtered to remove impurities before use. Second, with 0.1 mol L -1 The potassium hydroxide solution is added dropwise to the above-mentioned transparent chitosan solution to change its pH value until the solution becomes milky white, and the pH value of the solution at this time is 7.2. Chitosan nanoparticles are dispersed in the solution, and the obtained chitosan nanoparticle dispersion is used in the preparation of Pickering emulsion later.

[0033] (2) Fe 3 o 4 Preparation of Nanoparticles and Its Hydrophobic Modificati...

Embodiment 2

[0048] 1. A method for preparing a magnetic molecular imprinting adsorbent by Pickering emulsion polymerization, characterized in that it is carried out according to the following steps:

[0049] (1) Preparation of chitosan nanoparticles

[0050] First, 0.2 g of acetic acid was added dropwise to 100 mL of distilled water. Then add 0.2 g of chitosan into the weak acid solution with a pH value of about 3.8 and keep stirring. The resulting solution was filtered to remove impurities before use. Secondly, with 0.1mol L -1 The potassium hydroxide solution is added dropwise to the above-mentioned transparent chitosan solution to change its pH value until the solution becomes milky white, and the pH value of the solution at this time is 7.2. Chitosan nanoparticles are dispersed in the solution, and the obtained chitosan nanoparticle dispersion is used in the following Pickering emulsion preparation.

[0051] (2) Fe 3 o 4 Preparation of Nanoparticles and Its Hydrophobic Modificatio...

Embodiment 3

[0066] 1. A method for preparing a magnetic molecular imprinting adsorbent by Pickering emulsion polymerization, characterized in that it is carried out according to the following steps:

[0067] (1) Preparation of chitosan nanoparticles

[0068] First, 0.25 g of acetic acid was added dropwise to 100 mL of distilled water. Then add 0.3 g of chitosan into the weak acid solution with a pH value of about 3.5 and keep stirring. The resulting solution was filtered to remove impurities before use. Secondly, with 0.1mol L -1 The potassium hydroxide solution is added dropwise to the above-mentioned transparent chitosan solution to change its pH value until the solution becomes milky white, and the pH value of the solution at this time is 7.2. Chitosan nanoparticles are dispersed in the solution, and the obtained chitosan nanoparticle dispersion is used in the following Pickering emulsion preparation.

[0069] (2) Fe 3 o 4 Preparation of nanoparticles and their hydrophobic modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com