Cobalt-vanadium binary oxide type selective catalytic reduction supported catalyst for diesel engine

A technology of binary oxides and supported catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical/physical processes, etc., can solve the catalytic performance of unfavorable supported catalysts for low-temperature SCR reactions , poor low temperature activity, poor oxygen storage performance and other problems, to improve the catalytic performance of low temperature SCR reaction, reduce the harm to the environment and human health, and enhance the effect of oxygen storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

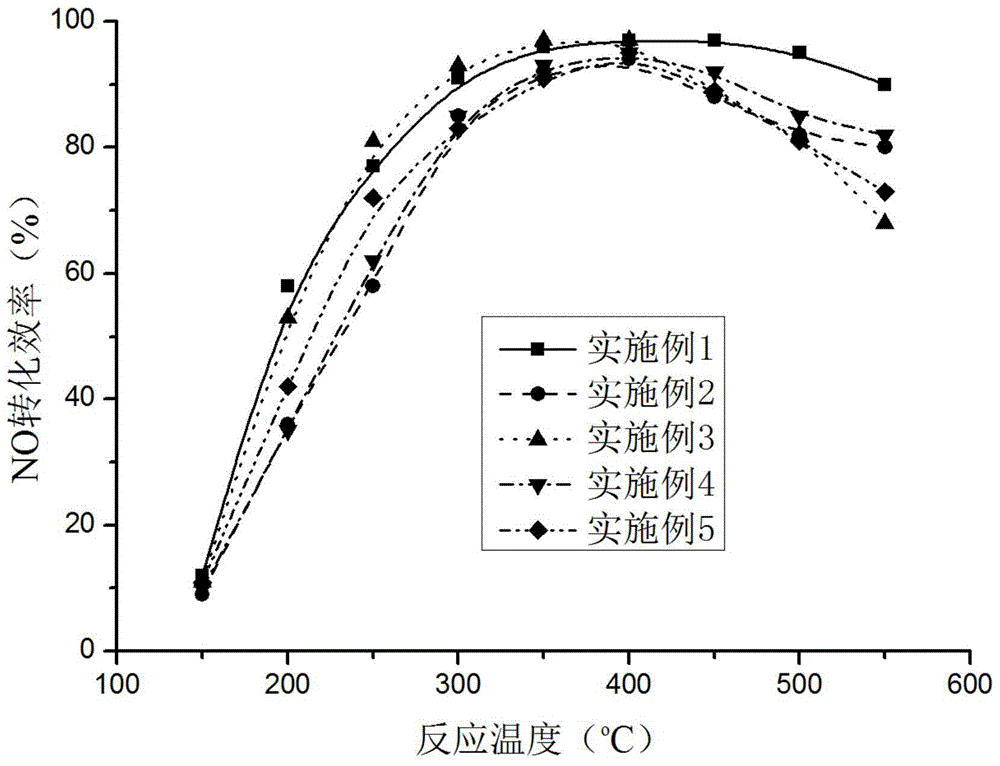

Embodiment 1

[0030] (1) Determination of the amount of catalyst raw material used

[0031] The design requires the preparation of Co in the main active component of the catalyst 2 o 3 and V 2 o 5 The mass ratio is: 66.7%: 33.3%; the mass ratio of the main active ingredient, co-catalyst and coating additive is: 3%: 9%: 88%; in the coating additive, CeO 2 , ZrO 2 , γ-Al 2 o 3 and anatase TiO 2 The mass ratio is: 20%:10%:20%:50%; pure γ-Al in coating additives 2 o 3 Transformation of powder and aluminum sol to generate γ-Al 2 o 3 The mass ratio of the coating is: 50%:50%; the mass ratio of the coating to the carrier is 20%:80%. The planned 400-mesh cordierite honeycomb ceramic carrier to be coated is 800g, based on which the content of various components in the cobalt-vanadium binary oxide type selective catalytic reduction supported catalyst can be calculated: Co 2 o 3 4g, V 2 o 5 2g, WO 3 18g, CeO 2 35.2g, ZrO 2 17.6g, pure γ-Al 2 o 3 γ-Al converted from powder 17.6g...

Embodiment 2

[0039] (1) Determination of the amount of catalyst raw material used

[0040] The design requires the preparation of Co in the main active component of the catalyst 2 o 3 and V 2 o 5 The mass ratio is: 50%:50%; the mass ratio of the main active ingredient, co-catalyst and coating aid is: 2%:5%:93%; in the coating aid, CeO 2 , ZrO 2 , γ-Al 2 o 3 and anatase TiO 2 The mass ratio is: 30%:0%:30%:40%; pure γ-Al in coating additives 2 o 3 Transformation of powder and aluminum sol to generate γ-Al 2 o 3 The mass ratio of the coating is: 50%:50%; the mass ratio of the coating to the carrier is 30%:70%. The planned 400-mesh cordierite honeycomb ceramic carrier to be coated is 700g, based on which the content of various components in the cobalt-vanadium binary oxide type selective catalytic reduction supported catalyst can be calculated: Co 2 o 3 3g, V 2 o 5 3g, WO 3 15g, CeO 2 83.7g, pure γ-Al 2 o 3 Powder 41.85g, γ-Al converted from aluminum sol 2 o 3 41.85g ...

Embodiment 3

[0048] (1) Determination of the amount of catalyst raw material used

[0049] The design requires the preparation of Co in the main active component of the catalyst 2 o 3 and V 2 o 5 The mass ratio is: 50%: 50%; the mass ratio of the main active ingredient, cocatalyst and coating aid is: 8%: 20%: 72%; in the coating aid, CeO 2 , ZrO 2 , γ-Al 2 o 3 and anatase TiO 2 The mass ratio is: 30%:0%:50%:20%; pure γ-Al in coating additives 2 o 3 Transformation of powder and aluminum sol to generate γ-Al 2 o 3 The mass ratio is: 50%:50%; the mass ratio of the coating to the carrier is 10%:90%. The planned 400-mesh cordierite honeycomb ceramic carrier to be coated is 900g, based on which the content of various components in the cobalt-vanadium binary oxide type selective catalytic reduction supported catalyst can be calculated: Co 2 o 3 4g, V 2 o 5 4g, WO 3 20g, CeO 2 21.6g, pure γ-Al 2 o 3 Powder 18g, γ-Al converted from aluminum sol 2 o 3 18g and anatase TiO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com