Ceramic fireproof optical fiber composite power cable

A power cable and ceramicization technology, applied in the direction of power cables, insulated cables, cables, etc., can solve the problems of difficult promotion, large capital investment, easy to fall off, etc., and achieve the effects of simple overall structure, guaranteed fire prevention effect, and large transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

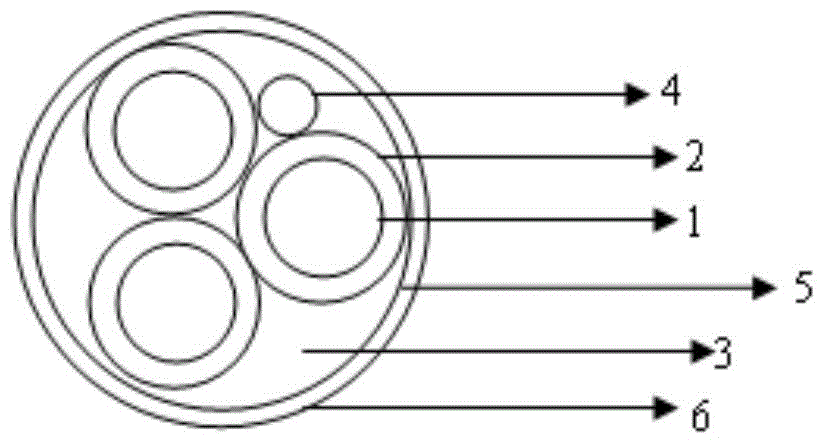

[0016] Such as figure 1 As shown, a ceramicized fireproof and refractory optical fiber composite power cable according to the present invention includes a conductor 1, and there are three conductors 1, and an inner ceramicized fireproof and refractory composite tape 2 is provided outside the conductor 1. A filling layer 3 is arranged on the outside of the inner ceramicized fireproof and refractory composite belt 2, and an optical fiber 4 is arranged inside the filled layer 3, and an outer ceramicized fireproof and refractory composite belt 5 is arranged on the outside of the filled layer 3. The outer ceramicized fireproof and refractory composite tape 5 is provided with a low-smoke and halogen-free jacket layer 6; the conductor 1 is a copper conductor; the optical fiber 4 is provided with a conductor 1 of an inner ceramicized fireproof and refractory co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com