A method for processing inferior heavy oil

A technology for low-quality heavy oil and heavy oil, which is applied in the fields of hydrotreating process, hydrocarbon oil cracking, petroleum industry, etc., and can solve the problem of not significantly improving the economic benefits of RFCC units, increasing the amount of coke and regenerator load, and the unsustainable hydrogenation of residual oil. Periodic operation and other issues to achieve the effect of improving the yield and product quality of catalytic cracking liquid products, reducing the yield of gas and coke, and improving the yield of catalytic cracking liquid products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

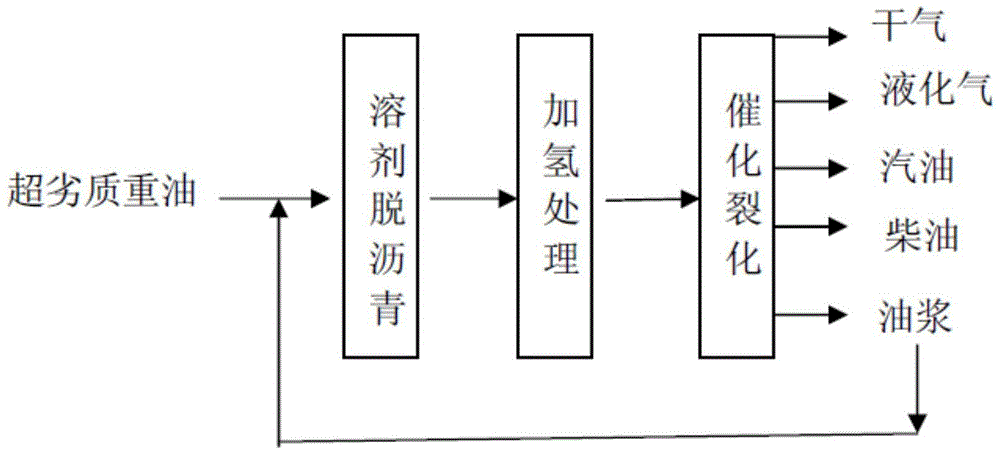

[0045] Example 3: Selective Solvent Deasphalting of Residual Oil - Mild Hydrotreating - Catalytic Cracking

[0046] The vacuum residue WVR of a low-quality crude oil in Venezuela was selected as raw material, and deasphalting was carried out with pentane as solvent to obtain deasphalted oil WDAO. See Table 4 for the properties of the deasphalted oil WDAO.

[0047] Table 4 Properties of Venezuelan deasphalted oil (WDAO)

[0048]

[0049] WDAO is used as the feed for hydrotreatment, and the reaction conditions of hydrotreatment are temperature 390°C, pressure 9MPa, liquid hourly space velocity 1.0h -1 , the catalyst is selected from C1 series catalysts (combined catalysts, of which 30% are demetallization catalysts, 40% are hydrodenitrogenation catalysts, 5% are post-treatment catalysts, and the rest are hydrodesulfurization catalysts; Weakly acidic macroporous alumina is used as the carrier, loaded with 1% NiO and 5% MoO 3 ; The denitrification catalyst uses alumina as th...

Embodiment 4

[0052] Example 4: Selective Solvent Deasphalting of Residual Oil - Hydrotreating - Catalytic Cracking

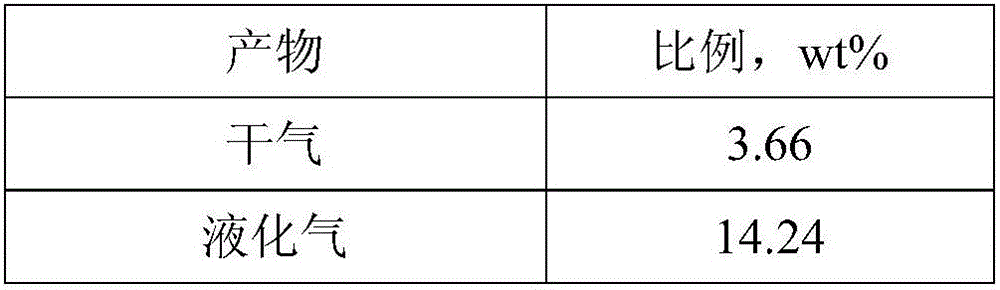

[0053] A low-quality vacuum residue oil WVR from Venezuela was selected as raw material, and deasphalted oil WDAO was obtained by selective solvent deasphalting with pentane as solvent. WDAO is used as the feed for hydrotreating, and the reaction conditions of hydrotreating are temperature 390°C, pressure 14MPa, liquid hourly space velocity 1.0h -1 , The catalyst is a C1 series catalyst. The catalytic cracking experiment of hydrotreated oil was carried out on a small fixed fluidized bed reactor, using LBO-16 catalyst, the catalytic cracking reaction temperature was 500°C, the catalyst-to-oil ratio was 5, and the space velocity was 30h -1 . The yields of catalytic cracking dry gas, liquefied gas, gasoline, diesel and heavy oil were measured, and the amount of coke on the catalyst was analyzed. The distribution of catalytic cracking products is shown in Table 6.

[0054] Pr...

Embodiment 5

[0056] Example 5 Selective Solvent Deasphalting of Residual Oil - Hydroprocessing - Catalytic Cracking - Oil Slurry Reverse Blending Hydroprocessing Raw Material

[0057] A low-quality vacuum residue oil WVR from Venezuela was selected as raw material, and deasphalted oil WDAO was obtained by selective solvent deasphalting with pentane as solvent. WDAO is mixed with the heavy oil slurry (HCO) obtained by catalytic cracking in Example 3 according to the mass ratio WDAO / HCO=9, and the mixture is used as the feed for hydrotreating, and the reaction condition of hydrotreating is a temperature of 390° C. , pressure 14MPa, liquid hourly space velocity 1.0h -1 , The catalyst is a C1 series catalyst. The catalytic cracking experiment of hydrotreated oil was carried out on a small fixed fluidized bed reactor, using LBO-16 catalyst, the catalytic cracking reaction temperature was 500°C, the catalyst-to-oil ratio was 5, and the space velocity was 30h -1 . The yields of catalytic crack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com