A kind of technology that utilizes swill to prepare bio-growth promoting agent

A bio-growth-promoting agent and swill technology, applied in water pollutants, biological water/sewage treatment, special compound water treatment, etc., can solve problems such as poor solubility, limited microbial absorption, limited supplementary nutrients, etc., to reduce The effect of economical cost and ease of use by microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1, this technique is made up of following steps:

[0013] (1) Separating the collected kitchen swill from solid impurities, and removing the oil layer on the surface of the swill; then performing centrifugal dehydration on the swill, crushing the dehydrated swill sediment, and setting aside;

[0014] (2) According to the percentage by weight, take 45-50% of the swill sediment prepared in the step (1), prepare with 5-8% of corn flour and 42-50% of tap water, and the sum of the percentages of each component is 100%. Then put it in a pressure cooker, keep the pressure at 0.048-0.110MPa, temperature 111-122°C, and after 1-1.2 hours, turn on the pressure cooker to obtain the base liquid of the bio-promoter, and set it aside; (3) to be prepared in step (2) The temperature of the good bio-growth-promoting agent base solution is lowered to 5-10°C, add 3-3.5% of pancreatic digestive enzyme solution, keep the temperature at 45-50°C, stir evenly, and react for 2-2.5h to...

Embodiment 2、1

[0018] Embodiment 2, 1. Go to the sanitation station to obtain swill, first separate the solid impurities in the swill in the solid impurity separation equipment, use the principle of isobiter to absorb the oil layer on the surface of the swill, and then pass the swill without solid impurities into The solid-liquid separator is used for centrifugal dehydration, and then the dehydrated sediment is crushed and crushed with a pulverizer; 2. The ratio of 45% of the treated swill, 5% of corn flour, and 50% of tap water is prepared and placed in the pot .

[0019] 3. Increase the pressure to 0.048MPa, the temperature is 111°C, turn off the switch about 1 hour after the pressure is reached, and turn on the pressure cooker after 30 minutes of heat preservation to obtain the base liquid of the bio-growth accelerator, and set it aside;

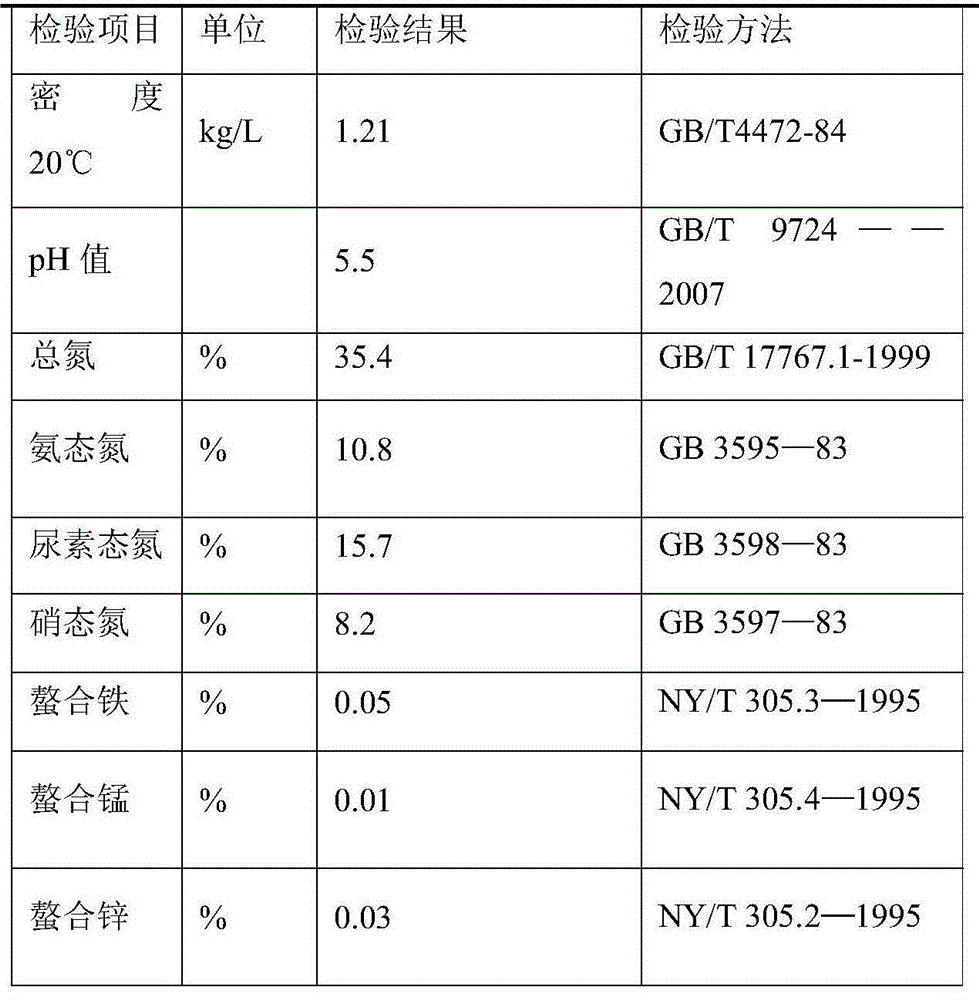

[0020] 4. Preparation of pancreatic digestive enzyme liquid, wherein the proportion of pancreatic digestive enzyme liquid is: pancreatic digestive enzy...

Embodiment 3、1

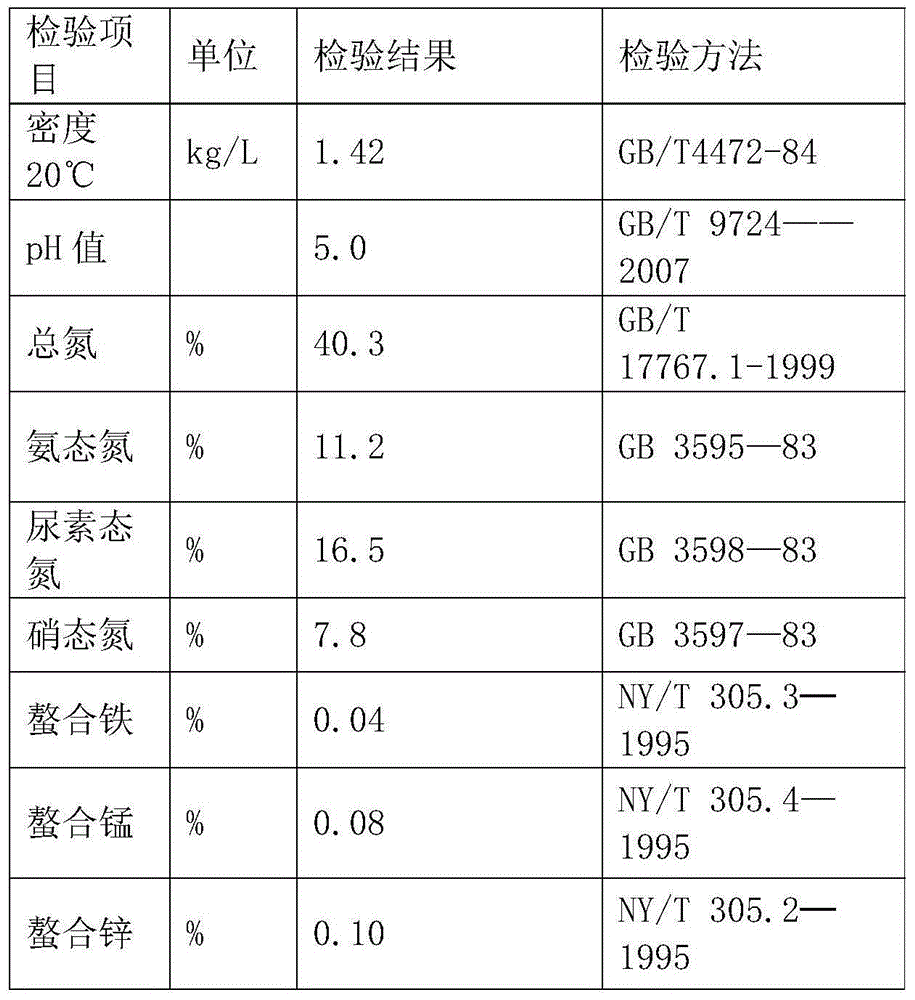

[0026] Embodiment 3, 1. Go to the sanitation station to obtain swill, first separate the solid impurities in the swill in the solid impurity separation equipment, use the principle of isobiter to absorb the oil layer on the surface of the swill, and then pass the swill without solid impurities into The solid-liquid separator is used for centrifugal dehydration, and then the dehydrated sediment is crushed and crushed with a pulverizer; 2. The ratio of 50% of the treated swill, 8% of corn flour, and 42% of tap water is prepared and placed in the pot .

[0027] 3. Increase the pressure to 0.110MPa, the temperature is 122°C, turn off the switch about 1.2 hours after the pressure reaches, and turn on the pressure cooker after 40 minutes of heat preservation to obtain the base liquid of the bio-promoter, and set it aside;

[0028] 4. Preparation of pancreatic digestive enzyme liquid, wherein the proportion of pancreatic digestive enzyme liquid is: pancreatic digestive enzyme 8%, wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com