Rolling Process of Thin Slab Continuous Casting and Rolling Medium and High Carbon Steel

A thin slab continuous casting, medium and high carbon technology, which is applied in the field of steel rolling technology, can solve the problems of fast cooling speed, high strength and hardness of thin slabs, and increased product flow, and achieves the advantages of avoiding annealing process, good mechanical properties and simplifying production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

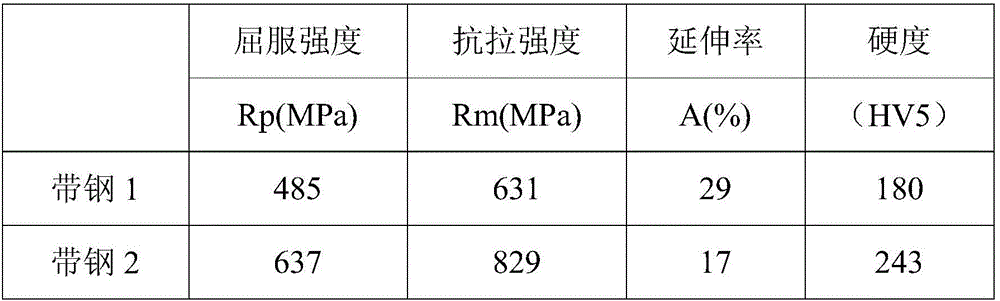

[0024] The 30CrMo strip steel is produced in the 7-stand thin slab continuous casting and rolling production line. The steps include: continuous casting, soaking, descaling, rolling, cooling between stands, laminar cooling, coiling, and slow cooling in the heat preservation cover. process. The main chemical composition of strip steel 30CrMo is: 0.3%C, 0.28%Si, 0.5%Mn, 0.9%Cr, 0.2%Mo, and the product thickness is 3mm. The thickness of the slab in the continuous casting process is 60mm. The rolling reductions of each pass are shown in Table 1.

[0025] Table 1 Example 1 The reduction rate of each pass

[0026] F1 F2 F3 F4 F5 F6 F7 Reduction rate 55% 58% 0 38% 28% 25% 20%

[0027] The soaking temperature is 1080°C, and the soaking time is 30 minutes. The descaling pressure is set to 30Mpa, the rolling start temperature is 980°C, the finish rolling temperature is 750°C, the cooling water pressure between the racks is 0.3Mpa, the strip exit speed...

Embodiment 2

[0037] The strip steel 50CrV4 is produced in the 6-stand thin slab continuous casting and rolling production line. The steps include: continuous casting, soaking, descaling, rolling, cooling between stands, laminar cooling, coiling, and slow cooling in the heat preservation cover. process. The chemical composition of strip steel 50CrV4 is: 0.5%C, 0.25%Si, 0.8%Mn, 1.0%Cr, 0.15%V, and the product thickness is 4mm. The thickness of the slab in the continuous casting process is 58mm, and the rolling reduction of each pass is shown in Table 4.

[0038] Table 4 The reduction rate of each pass of embodiment 2

[0039] F1 F2 F3 F4 F5 F6 Reduction rate 50% 55% 0 35% 30% 25%

[0040] The soaking temperature is 1120°C, and the soaking time is 35 minutes. The descaling pressure is set to 25Mpa, the rolling start temperature is 1030°C, the finish rolling temperature is 800°C, the cooling water pressure between the racks is 0.3Mpa, the strip exit speed at F7...

Embodiment 3

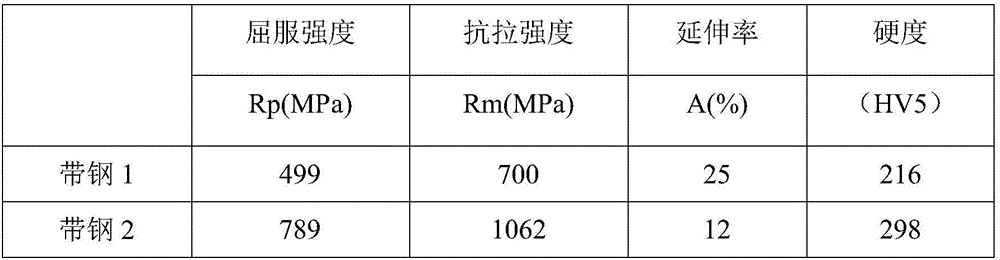

[0050] The 30CrMo strip steel is produced in the 7-stand thin slab continuous casting and rolling production line. The steps include: continuous casting, soaking, descaling, rolling, cooling between stands, laminar cooling, coiling, and slow cooling in the heat preservation cover. process. The main chemical composition of strip steel 30CrMo is: 0.3%C, 0.28%Si, 0.5%Mn, 0.9%Cr, 0.2%Mo, and the product thickness is 3mm. The thickness of the slab in the continuous casting process is 60mm. The rolling reductions of each pass are shown in Table 7.

[0051] Table 7 The reduction rate of each pass of embodiment 3

[0052] F1 F2 F3 F4 F5 F6 F7 Reduction rate 56% 58% 5% 38% 28% 25% 20%

[0053] The soaking temperature is 1050°C, and the soaking time is 40 minutes. The descaling pressure is set to 30Mpa, the rolling start temperature is 950°C, the finish rolling temperature is 700°C, the cooling water pressure between the racks is 0.4Mpa, the strip exit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com