X52 seamless pipeline tube having HIC resistance and manufacturing method thereof

A technology of seamless line pipe and manufacturing method, which is applied to manufacturing tools, heat treatment equipment, furnaces, etc., to achieve the effects of low production cost, good stability and uniform grain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below by embodiment the present invention will be further described.

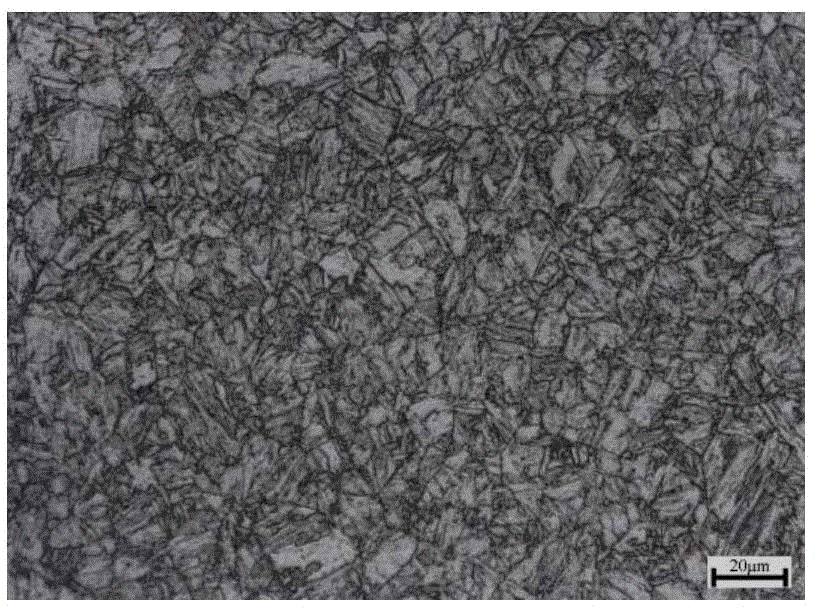

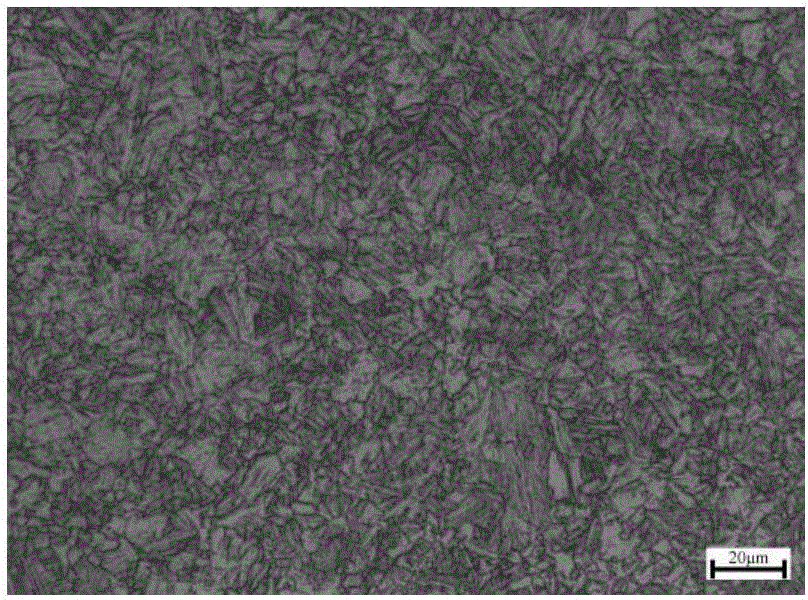

[0026] In the embodiment of the present invention, according to the component distribution ratio of the technical solution, the tube blank is obtained through converter smelting, LF refining (LF), continuous casting, and continuous rolling. Carry out quenching + tempering heat treatment, and then carry out temperature straightening and flaw detection inspection. See Table 1 for the smelting composition of the steel of the embodiment of the present invention and the steel of the comparative example. The main process parameters of the steel of the embodiment of the present invention and the steel of the comparative example are shown in Table 2. The properties of the steels of the examples of the present invention and the steels of the comparative examples are shown in Table 3, and the results of the steels of the examples of the present invention and the steels of the comparative examples are shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com