Molybdenum disulfide/sulfur-and-nitrogen-doped graphene nanosheet composite material as well as preparation method and application thereof

A technology of nitrogen-doped graphene and graphene nanosheets, which is applied in the field of nanocomposite materials and its preparation, can solve the problems of small sample yield, poor conductivity, and enlarged electron transmission path, and achieve simple preparation method and large specific surface area , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

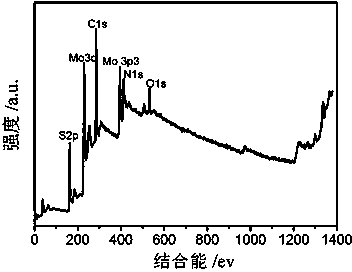

[0026] A molybdenum disulfide / sulfur and nitrogen-doped graphene nanosheet composite material of the present invention, in the composite material, molybdenum disulfide is loaded on sulfur, nitrogen-doped graphene nanosheet; the composite material is a diameter of 40 ~ 100nm wafer.

[0027] The preparation method of the molybdenum disulfide / sulfur and nitrogen-doped graphene nanosheet composite material of the present embodiment comprises the following steps: taking by weighing 0.22g ammonium tetrathiomolybdate, 0.15g graphene oxide, and 1.5g thiourea respectively, Dissolve in 150mL DMF and ultrasonically mix evenly, remove most of the solvent by rotary evaporation in an oil bath at 110°C with a rotary evaporator, take out the sample and dry it in vacuum at 120°C in a watch glass, take it out after complete drying, and grind it with a mortar Put it in a quartz boat, put it in a tube furnace, connect argon / hydrogen (10%) and argon with a three-way connection, and then use soapy ...

Embodiment 2

[0031] A molybdenum disulfide / sulfur and nitrogen-doped graphene nanosheet composite material of the present invention, in the composite material, molybdenum disulfide is loaded on sulfur, nitrogen-doped graphene nanosheet; the composite material is a diameter of 40 ~ 100nm wafer.

[0032]The preparation method of the molybdenum disulfide / sulfur and nitrogen-doped graphene nanosheet composite material of the present embodiment comprises the following steps: respectively weigh 0.3g ammonium tetrathiomolybdate, 0.15g graphene oxide, 2g thiourea, dissolve After ultrasonically mixing in 500mL DMF, use a rotary evaporator to remove most of the solvent in an oil bath at 90°C, then take out the sample and dry it under vacuum at 100°C in a watch glass, take it out after it is completely dry, grind it with a mortar, and place it Put it in a quartz boat, put it in a tube furnace, connect argon / hydrogen (10%) and argon with a tee, and then use soapy water to check for leaks, check whethe...

Embodiment 3

[0035] A molybdenum disulfide / sulfur and nitrogen-doped graphene nanosheet composite material of the present invention, in the composite material, molybdenum disulfide is loaded on sulfur, nitrogen-doped graphene nanosheet; the composite material is a diameter of 40 ~ 100nm wafer.

[0036] The preparation method of the molybdenum disulfide / sulfur and nitrogen-doped graphene nanosheet composite material of the present embodiment comprises the following steps: taking by weighing 0.2g ammonium tetrathiomolybdate, 0.2g graphene oxide, and 2.5g thiourea respectively, Dissolve in 1000mL DMF and ultrasonically mix evenly, remove most of the solvent by rotary evaporation in an oil bath at 100°C with a rotary evaporator, take out the sample and dry it in vacuum at 80°C in a watch glass, take it out after it is completely dry, and grind it finely with a mortar Put it in a quartz boat, put it in a tube furnace, connect argon / hydrogen (10%) and argon with a three-way connection, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com