Organic solar cell and preparation method thereof

A solar cell and organic technology, which is applied in the manufacturing/processing of organic semiconductor devices, organic semiconductor devices, circuits, etc., can solve the problems of unapplied electron transport layers, etc., to reduce production costs, improve device stability, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

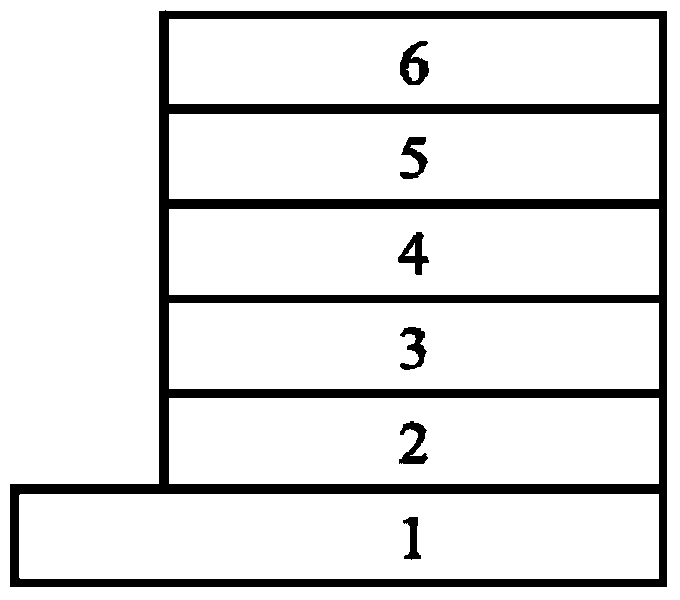

[0033] Example 1. Method for the preparation of organic solar cells.

[0034] (1) After the patterned ITO glass substrate 1 is ultrasonically cleaned with acetone, detergent, deionized water, and isopropanol, it is dried and exposed to ultraviolet light for 15 minutes to prepare an electron transport substrate for an organic solar cell on the substrate. layer 2, 3;

[0035] (2) Give the photoactive layer to the acceptor material PTB7 and PC 71 BM (mass ratio 2:3) was uniformly mixed, dissolved with 97% chlorobenzene and 3% DIO solution (total concentration 52mg / ml), stirred at 60°C for 48h, filtered and spin-coated on the electron transport layer, That is to obtain the active layer 4, the said rotating speed is 1000rpm, and the time is 2min;

[0036] (3) Dry the sample coated with the active layer for 2h under nitrogen conditions;

[0037] (4) Finally, the sample coated with the dry active layer is transferred to the evaporation equipment, and 7nm molybdenum trioxide 5 (ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com