Quartz crucible for single crystal growth and preparation method of quartz crucible for single crystal growth

A quartz crucible and single crystal technology, applied in the field of ceramics, can solve problems such as crucible cracking, and achieve the effects of good chemical durability, strong covalent bond characteristics, and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

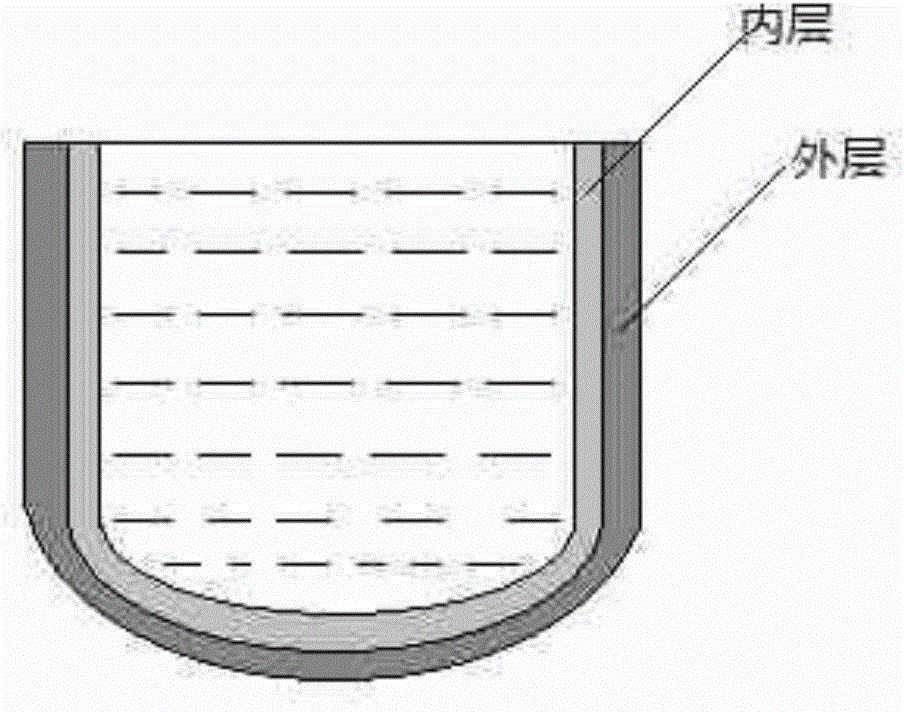

[0015] A quartz crucible for single crystal growth, 0.5mm natural silica sand, 10nm nano-silicon dioxide, 0.5μm aluminum nitride, 0.5μm silicon nitride are mixed evenly in a mass ratio of 90:1:1:2 In the crucible mold, the outer layer is formed by melting at 1500°C; the thickness of the outer layer is 8mm.

[0016] After mixing, 0.5mm pure quartz and 50nm nano-silicon dioxide particles are mixed at a mass ratio of 90:2. They are melted at 1500° C. to form an inner layer inside the outer layer, and the thickness of the inner layer is 1 mm.

[0017] The dimensions of the quartz crucible are as follows: outer diameter 300 mm, height 200 mm.

[0018] Experimental results: The inner layer of the prepared crucible is transparent and free of bubbles. It can be used continuously for 100 hours at a high temperature of 1500 ℃, and its strength reaches 200MPa without cracking.

Embodiment 2

[0020] A quartz crucible for single crystal growth, mix 2mm natural silica sand, 80nm nano-silica, 0.5μm alumina, 0.5μm silicon nitride in a mass ratio of 85:0.5:0.5:1 and put them into the crucible mold evenly In the middle, the outer layer is formed by melting at 1500°C; the thickness of the outer layer is 10mm.

[0021] After mixing, 1.5mm pure quartz and 20nm nano-silicon dioxide particles are mixed at a mass ratio of 90:10. They are melted at 1500° C. to form an inner layer inside the outer layer, and the thickness of the inner layer is 2 mm.

[0022] The dimensions of the quartz crucible are as follows: outer diameter 300 mm, height 200 mm.

[0023] Experimental results: The inner layer of the prepared crucible is transparent and free of bubbles. It can be used continuously at a high temperature of 1500°C for 40 hours at one time, and its strength reaches 190MPa without cracking.

Embodiment 3

[0025] A quartz crucible for single crystal growth. Mix 1mm natural silica sand, 100nm nano-silicon dioxide, 0.5μm titanium oxide, and 0.5μm silicon nitride in a mass ratio of 95:1.5:1.5:3 and put them evenly into the crucible mold In the middle, the outer layer is formed by melting at 1500°C; the thickness of the outer layer is 9mm.

[0026] After mixing, 2mm pure quartz and 100nm nanometer silicon dioxide particles are mixed at a mass ratio of 90:5. Melted at 1500° C. to form an inner layer inside the outer layer, the thickness of the inner layer is 1.5 mm.

[0027] The dimensions of the quartz crucible are as follows: outer diameter 300 mm, height 200 mm.

[0028] Experimental results: The inner layer of the prepared crucible is transparent and free of bubbles. It can be used continuously for 60 hours at a high temperature of 1500°C, and its strength reaches 180MPa without cracking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com