Self-lubrication alloying galvanized steel plate for automobiles and preparation method of self-lubrication alloying hot galvanized steel plate

A hot-dip galvanized steel sheet and self-lubricating technology, which is applied in the field of self-lubricating alloyed hot-dip galvanized steel sheet, can solve the problems of complex production process and high production cost, and achieve the expansion of deep drawing processing range, high production efficiency, and avoidance of process cumbersome effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

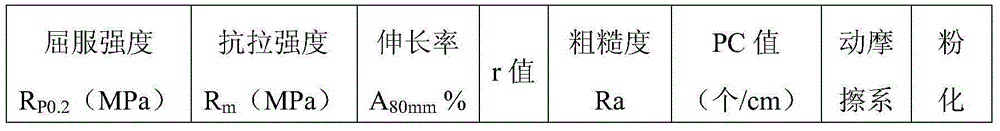

[0038] The weight percentage of chemical composition is: C: 0.0012%, Si: 0.009%, Mn: 0.087%, P: 0.01%, S: 0.0063%, Als: 0.031%, Ti: 0.07%, N: 0.0025, and the rest is Fe and unavoidable impurities. The slab heating temperature is 1280°C, the hot rolling finishing temperature is 920°C, the coiling temperature is 710°C, the cold rolling reduction rate is 82%, the continuous annealing soaking temperature is 825°C, and the strip steel entering zinc pot temperature is 480°C , the alloying temperature is 520°C, the fair elongation is 1%, and the self-lubricating coating on one side is 0.3g / m 2 , drying plate temperature is 80 ℃. According to embodiment 1, the mechanical properties of steel are detected, yield strength R P0.2 : 165MPa, tensile strength Rm: 293MPa, elongation A 80mm %: 47.5, r: 2.0, the strength and plasticity match well.

[0039] Ordinary alloyed hot-dip galvanized sheet and self-lubricating alloyed hot-dip galvanized sheet coated with self-lubricating paint were ...

Embodiment 2

[0043] The weight percentage of chemical composition is: C: 0.0008%, Si: 0.008%, Mn: 0.097%, P: 0.013%, S: 0.0058%, Als: 0.032%, Ti: 0.074%, N: 0.0023, and the rest is Fe and unavoidable impurities. The slab heating temperature is 1280°C, the hot rolling finishing temperature is 930°C, the coiling temperature is 720°C, the cold rolling reduction rate is 85%, the continuous annealing soaking temperature is 830°C, and the strip steel entering zinc pot temperature is 490°C , the alloying temperature is 530°C, the fair elongation is 1.2%, and the self-lubricating coating on one side is 0.42g / m 2 , drying plate temperature is 85 ℃. According to embodiment 2, the mechanical properties of steel are detected, yield strength R P0.2 : 160MPa, tensile strength Rm: 285MPa, elongation A 80mm %: 45, r: 2.1, the strength and plasticity match well.

[0044] Ordinary alloyed hot-dip galvanized sheet and self-lubricating alloyed hot-dip galvanized sheet coated with self-lubricating paint we...

Embodiment 3

[0048] The weight percentage of chemical composition is: C: 0.001%, Si: 0.007%, Mn: 0.096%, P: 0.01%, S: 0.005%, Als: 0.03%, Ti: 0.069%, N: 0.0022, and the rest is Fe and unavoidable impurities. The slab heating temperature is 1280°C, the hot rolling finishing temperature is 925°C, the coiling temperature is 735°C, the cold rolling reduction rate is 80%, the continuous annealing soaking temperature is 835°C, and the strip steel entering zinc pot temperature is 485°C , the alloying temperature is 525°C, the fair elongation is 0.95%, and the self-lubricating coating on one side is 0.4g / m 2 , drying plate temperature is 90 ℃. According to embodiment 2, the mechanical properties of steel are detected, yield strength R P0.2 : 162MPa, tensile strength Rm: 290MPa, elongation A 80mm %: 47.5, r: 2.3, the strength and plasticity match well.

[0049] Ordinary alloyed hot-dip galvanized sheet and self-lubricating alloyed hot-dip galvanized sheet coated with self-lubricating paint were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com