Method for preparing phosphorus-magnesium fertilizer

A technology of phosphate magnesium fertilizer and phosphate fertilizer, which is applied in the direction of magnesium phosphate fertilizer, phosphate fertilizer, magnesium bisphosphate fertilizer, etc., can solve the problems of high product cost and large amount of raffinate, and achieve the effect of low cost and reduced treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

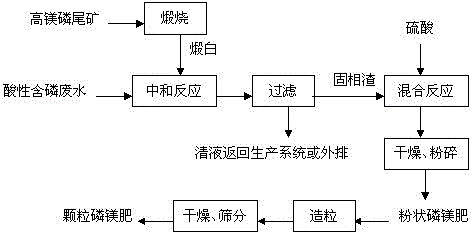

Image

Examples

preparation example Construction

[0032] The above-mentioned method for preparing phosphorus and magnesium fertilizers, wherein: high-magnesium phosphorus tailings are low-grade phosphorus pentoxide-containing minerals discharged after obtaining high-grade phosphorus pentoxide concentrate in the process of phosphate ore dressing.

[0033] The above-mentioned preparation method of a phosphorus magnesium fertilizer, wherein: the powdery phosphorus magnesium fertilizer product is granulated on a disc granulator or a drum granulator, dried and sieved to obtain a granular phosphorus magnesium fertilizer product.

Embodiment 1

[0036] Will P 2 o5 The high-magnesium phosphorus tailings with a content of 7.0% and a MgO content of 16.9% were calcined at 960 °C to obtain calcined white with a quality of 61% of the high-magnesium phosphorus tailings. 2 o 5 Add 104kg of the above-mentioned calcined white to the 1t phosphate fertilizer industrial acid phosphorus-containing waste water with a content of 4.0% and a pH value of 1.5 for neutralization and precipitation reaction, and filter the feed liquid when the pH value of the feed liquid is 8 to obtain clear liquid and phosphorus-containing magnesium solids. Phase slag (mass of about 135kg on a dry basis), the clear liquid is returned to the phosphate fertilizer production system or discharged when it meets the standard; add sulfuric acid with a dry basis mass of solid phase slag of 35% to the solid phase slag obtained from the filtration for 0.5h, and after the reaction, the reaction The product is dried and pulverized to obtain a specification of about 1...

Embodiment 2

[0038] Will P 2 o 5 The high-magnesium phosphorus tailings with 2.0% content and 21.0% MgO content were calcined at 1200 °C to obtain calcined white with a quality of 56% of the high-magnesium phosphorus tailings. 2 o 5 Add 30kg of the above-mentioned calcined white to 1t of phosphate fertilizer industrial acid phosphorus-containing waste water with a pH value of 3 for neutralization and precipitation reaction, and filter the feed liquid when the pH value of the feed liquid is 7 to obtain clear liquid and phosphorus-containing magnesium solids. Phase slag (mass of about 51kg on a dry basis), the clear liquid is returned to the phosphate fertilizer production system or discharged when it reaches the standard; add sulfuric acid with 10% of the dry mass of the solid phase slag to the solid phase slag obtained by filtering for 0.1h, and after the reaction, the reaction After the material is dried and crushed, it is granulated on a disc granulator to obtain about 58kg of effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com