Method for manufacturing ultra-fine high-toughness silicon carbide ceramic material based on reaction sintering method

A silicon carbide ceramic and sintering technology is applied in the field of manufacturing ultra-fine and high-toughness silicon carbide ceramic materials, which can solve the problems of poor design of the preparation method, and achieve the effects of high toughness, reduced production cost, and ultra-fine particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

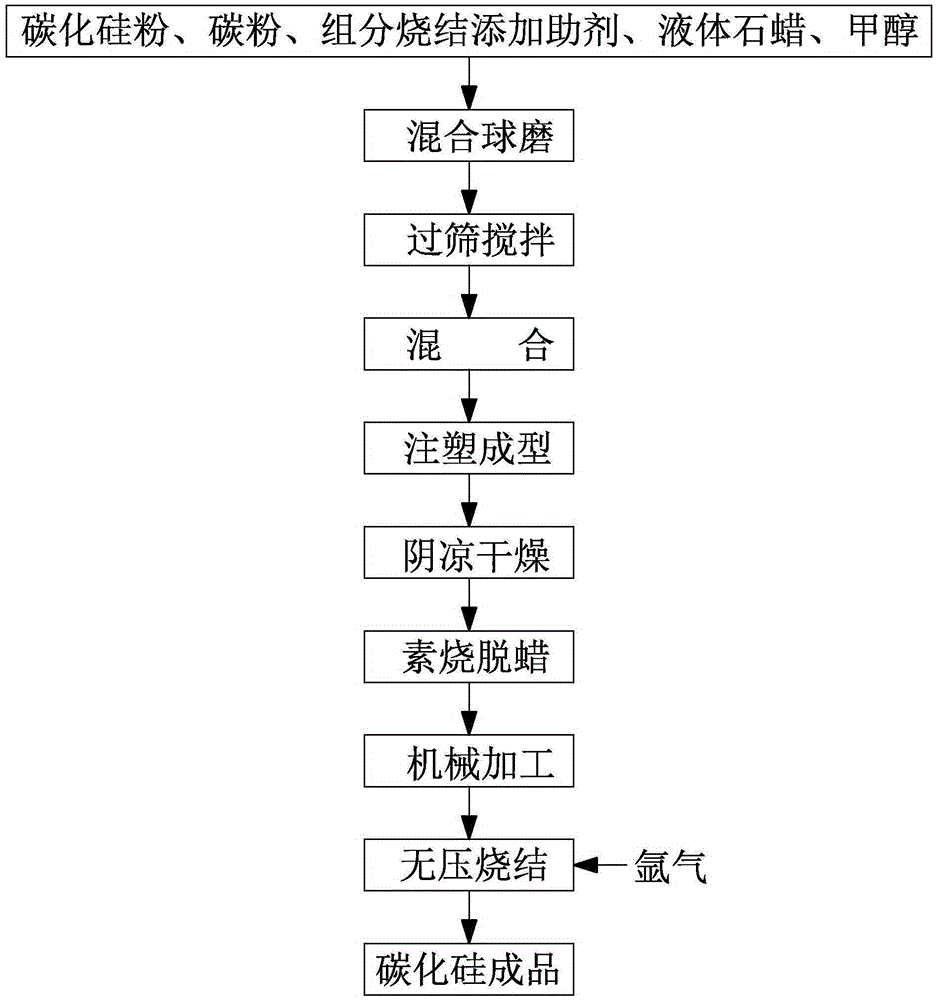

Method used

Image

Examples

Embodiment 1

[0025] Add 9g of Y to 500g of 0.50μm silicon carbide powder 2 o 3 -Al 2 o 3 -SiO 2 Component sintering Add additives and 15g of carbon powder, fully stir and mix through a mixer, pour into a solution in which 15g of liquid paraffin and 250ml of methanol have been dissolved in advance, and then go through agitation and ball milling to make mud; put the above mud in Stir in a stainless steel container with a stirrer for 12 hours, then inject the stirred slurry on an injection molding machine, and then dry and harden naturally in a cool place after molding. The biscuit formed after drying and hardening is bisque fired in a vacuum sintering furnace, and the additives and binders in the biscuit are removed. The temperature in the vacuum sintering furnace is 800 ° C, the vacuum degree is below 0.40 MPa, and sintering is carried out for 1.0 hour. A medium-strength green body can be obtained; the green body obtained above is processed into blanks of various shapes and sizes by mec...

Embodiment 2

[0027] Add 4.8g of Y to 500g of 0.86μm silicon carbide powder 2 o 3 -Al 2 o 3 -SiO 2 Component sintering Add additives and 9g of carbon powder, fully stir and mix through the mixer, pour into the solution of pre-dissolved 12g of liquid paraffin and 240ml of methanol, and then go through stirring and ball milling to make mud; put the above mud in the belt Stir in the stainless steel container of the stirrer for 15 hours, then inject the stirred slurry on an injection molding machine, and then dry and harden naturally in a cool place after molding. The biscuit formed after drying and hardening is biscuit-fired in a vacuum sintering furnace, and the additives and binders in the biscuit are removed. The temperature in the vacuum sintering furnace is 1200 ° C, the vacuum degree is below 0.40 MPa, and sintering is carried out for 2 hours. A green body with medium strength can be obtained; the above-mentioned green body is machined into various shapes and required blanks again, a...

Embodiment 3

[0029] First mix 25g liquid paraffin and 300ml methanol solution, then add 0.50μm 500g silicon carbide powder, 15g carbon powder, 7.5g Y 2 o 3 -Al 2 o 3 -SiO 2 The components are sintered and additives are added to make slurry, Y 2 o 3 -Al 2 o 3 -SiO 2 Component sintering additive is 1.5% of Y 2 o 3 -Al 2 o 3 -SiO 2 ; Then through stirring and ball milling, the mud is obtained; the green body after injection molding is cooled and dried in the air at room temperature of 20 ℃, and the green body is obtained. The green body has a certain shape and size after being molded, and the green body is Direct slices are arranged in the silicon layer for sintering, so that it can be completely immersed in the silicon vapor; sintering adopts a combination of vacuum and atmosphere, and the temperature is raised in vacuum in the low temperature area, which is higher than 1300 ° C. It is protected by an argon atmosphere to maintain the pressure in the furnace 0.12MPa; the heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com