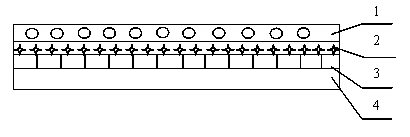

Metalized grinding paper with optical variability effect and preparation method thereof

A technology of aluminized paper and frosting, which is applied in the field of packaging materials and decorative materials, can solve the problems of weak anti-counterfeiting, and achieve the effect of fine and realistic frosting effect, thick metal texture and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) A micron-sized silicon oxide powder (frosting powder) is evenly dispersed by ball milling in a composition containing aqueous acrylic emulsion, polyvinyl alcohol, carboxymethyl cellulose, and water to form a coating with a frosting effect mixture, and then disperse a certain amount of optically variable pigments into the paint mixture, and disperse and mix evenly to obtain a water-soluble optically variable frosted paint;

[0037] The quality of each component of water-soluble optically variable frosted paint is:

[0038] Water-based acrylic emulsion 45kg;

[0039] Polyvinyl alcohol 3kg;

[0040] Carboxymethyl cellulose 3kg;

[0041] Silicon oxide powder 8kg;

[0042] 20kg of water;

[0043] 10 kg of powdery optical variable pigments, the fineness of optical variable pigments is 30 μm.

[0044] Under normal circumstances, the silicon oxide powder added when making frosted paint is nano-scale or smaller micron-scale, the general particle size is below 2 μm, and ...

Embodiment 2

[0054] (1) In a composition containing epoxy acrylate photosensitive resin, tripropylene glycol diacrylate, propoxylated trimethylolpropane triacrylate, monomaleimide resin, methylethanolamine, add A small amount of photoinitiator, dispersant and leveling agent uniformly disperses silicon oxide powder and optically variable pigments into the composition to form an ultraviolet light-curable frosted coating that can produce optically variable effects.

[0055] The ratio of each component of the UV-curable light-variable matte coating is:

[0056] Epoxy acrylate photosensitive resin 32kg

[0057] Tripropylene glycol diacrylate 15kg

[0058] Propoxylated Trimethylolpropane Triacrylate 15kg

[0059] Monomaleimide resin 5 kg

[0060] Wax modified silica powder 12kg

[0061] Photoinitiator 5 kg

[0062] Optical variable pigment 8kg

[0063] Dispersants and leveling agents are commercially available products commonly used in the industry in appropriate amounts to adjust the per...

Embodiment 3

[0073] (1) Add a small amount of dispersant and leveling agent to a composition containing epoxy acrylate prepolymer, tripropylene glycol diacrylate, polyurethane acrylate, and polyethylene glycol acrylate, and mix well. Pre-polymerize at room temperature for more than 24 hours to form a liquid composition coating suitable for electron beam curing. Add the frosting powder (fumed silicon oxide) and optical variable pigment in parts by weight, first pre-disperse with a high-speed disperser to eliminate the large particles of the grinding powder The emulsifying machine emulsifies and disperses, so that the frosting powder is fully dispersed in the liquid composition coating to form a homogeneous body. That is, an electron beam-cured frosted paint capable of producing light-changing effects is obtained.

[0074] The ratio of each component of the optically variable electron beam cured frosted coating is:

[0075] Take 35kg of epoxy acrylic acid prepolymer

[0076] Tripropylene g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com