Superplastic magnesium lithium alloy material with high strain rate and preparation method thereof

A high strain rate, magnesium-lithium alloy technology, applied in the preparation process of magnesium-lithium alloy materials, the field of magnesium-lithium alloy materials with high strain rate superplasticity, can solve complex processing technology, difficult to meet production needs, low strain rate, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in more detail below:

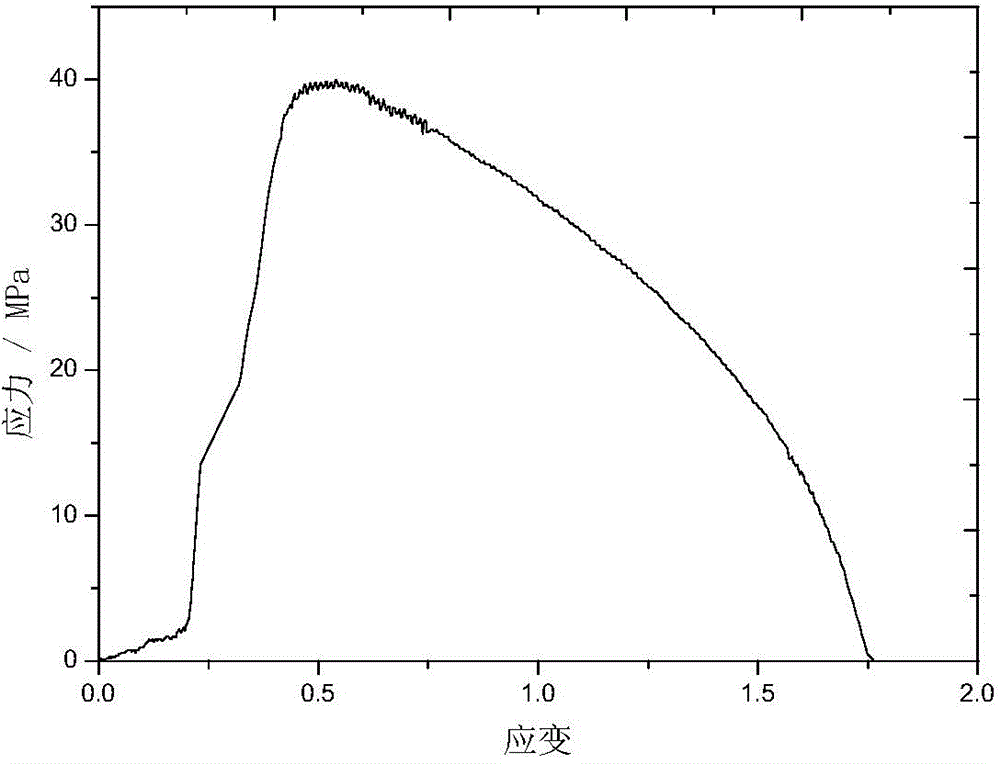

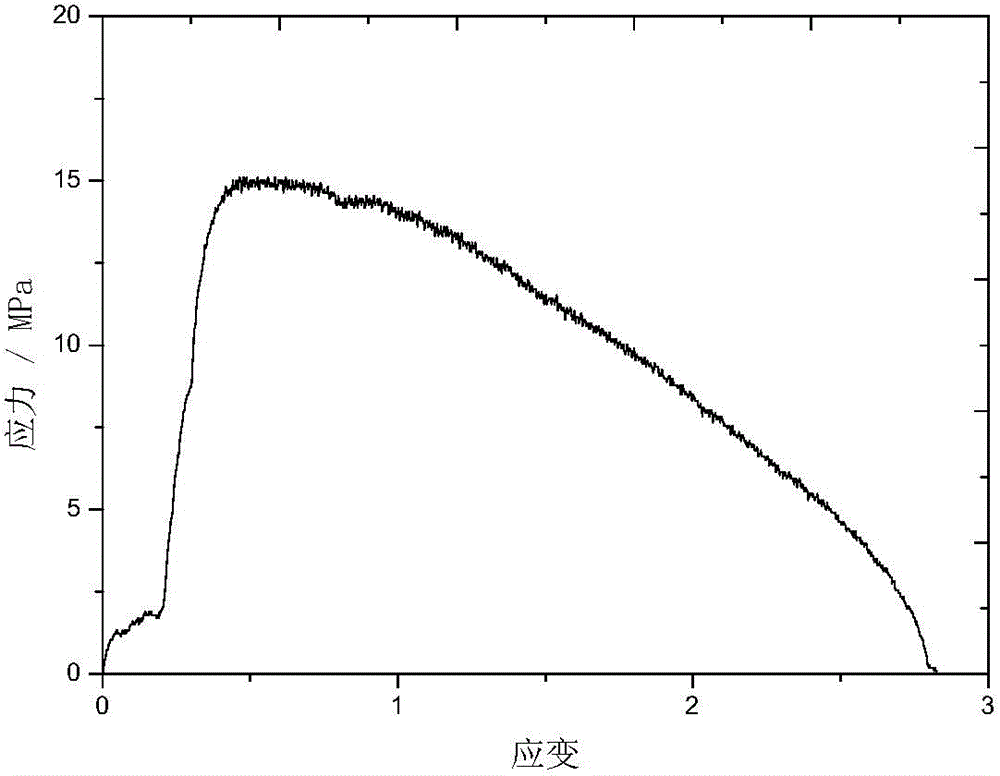

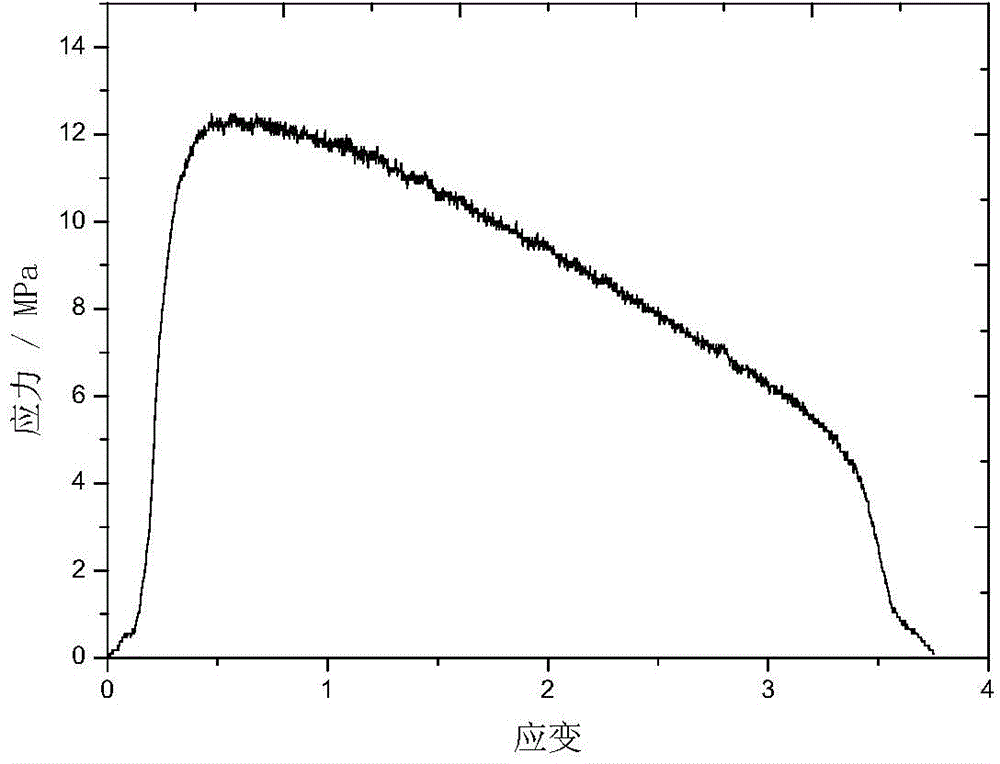

[0023] According to the mass percentage composition of the alloy composition: Li9%, Al1%, and the balance of Mg and trace impurity elements, a total of 1 kg of raw materials required for smelting the alloy is configured. Use a vacuum electromagnetic induction furnace to melt under the protection of argon. After filling the raw materials into the crucible, the furnace is vacuumed to below -0.1, and then filled with argon to make the vacuum degree to -0.05. At the beginning of smelting, preheat under 5kW for 5 minutes, then adjust the power to 7kW and heat for 10 minutes to observe the situation in the furnace until all the ingots are completely melted, then reduce the power to 3kW for 10 minutes, stop heating and start pouring immediately. The ingot is cooled in the vacuum furnace for at least 1.5 hours and then taken out. The obtained ingot is homogenized and annealed in a heat treatment furnace at 300°C for 12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com