Purification method of high-purity teicoplanin refined powder

A technology of coplanin refined powder and purification method, which is applied to the purification field of high-purity teicoplanin refined powder, can solve problems such as insufficient separation effect, and achieve the effects of reliable quality, controllable content and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

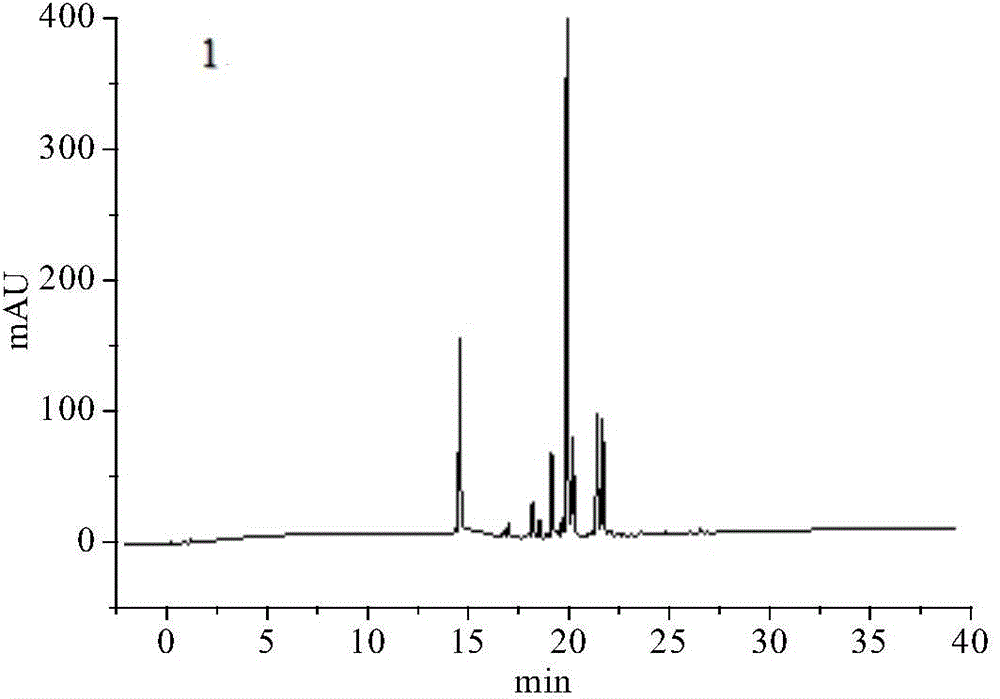

Embodiment 1

[0038] A. Adjust the pH of 60L of teicoplanin fermentation broth to 11.0, keep it at room temperature for about 15min, return to pH7.5, centrifuge at 4500rpm for 10min, take the supernatant and dilute it to 120L with 15L HP20 macroporous resin, first use 2BV (2 times Column volume) Pure water was eluted at a flow rate of 10L / h to remove impurities and pigments, and then eluted with 10%, 15%, 20%, and 25% acetone aqueous solution at a flow rate of 12L / h to remove impurities, and then 70% acetone The aqueous solution was eluted at a flow rate of 12 L / h, and the eluate with 70% acetone aqueous solution as the eluent was collected to obtain 216 L of the eluate, the content of teicoplanin was 822.03 g, the yield was 88.7%, and the potency was 13.70 g / L.

[0039] B. Concentrate the 216L eluate to a small volume under reduced pressure, put it on a 5L Sephadex gel chromatography column, first use 15% methanol water to elute at a flow rate of 8L / h, and then use a volume ratio of 35:65 m...

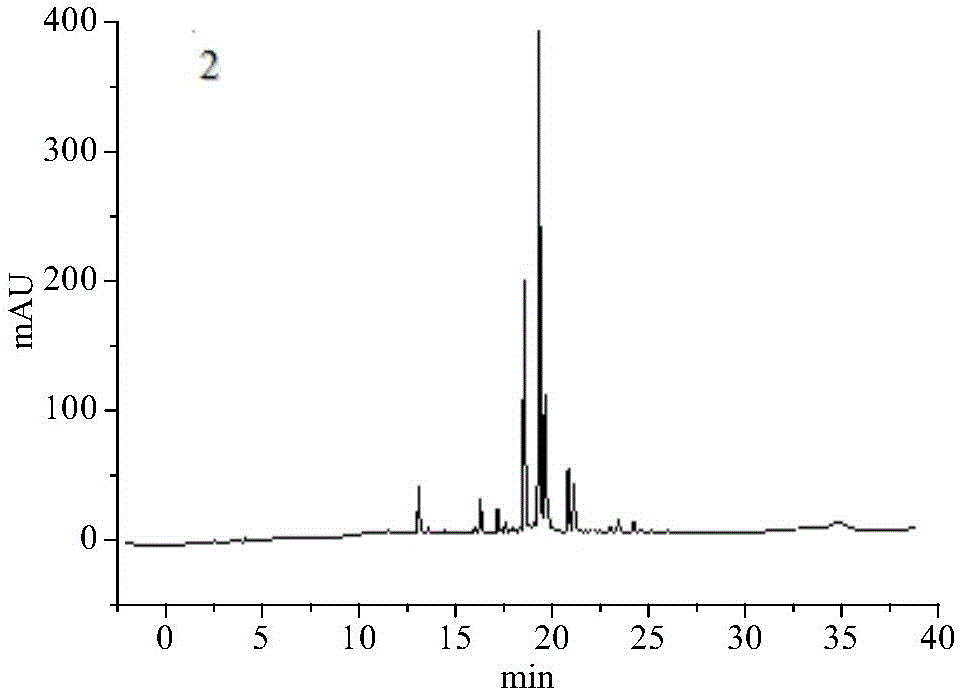

Embodiment 2

[0046] A. Adjust the pH of 60L of teicoplanin fermentation broth to 11.0, keep it at room temperature for about 15min, return to pH7.5, centrifuge at 4500rpm for 10min, take the supernatant and dilute it to 120L, take 20L of the diluted solution, and install it with D3520 macroporous resin for adsorption , first eluted with 2BV (column volume) pure water at a flow rate of 10L / h to remove impurities and pigments, and then eluted with 10%, 15%, 20%, and 25% acetone aqueous solution at a flow rate of 12L / h to remove impurities , and then eluted with 70% acetone aqueous solution at a flow rate of 12L / h, collecting the eluent with 70% acetone aqueous solution as the eluent, obtaining 81L eluent with a content of 270.8g and a titer of 13.54g / L, and recovering Teicoara Ning 245.34g, the yield is 90.6%, and the purity of the product by liquid chromatography is 83.01%.

[0047] B. Adsorb 81L of the eluate on a 5L agarose gel chromatography column with a sample loading flow rate of 6L / h...

Embodiment 3

[0054] The difference between this part and embodiment 1 is:

[0055] A. Take 20L of diluent and put it on HZ816 macroporous adsorption resin;

[0056] Obtain 75L eluent, teicoplanin content 210.4g, potency 14.04g / L, reclaim teicoplanin 192.30g, yield is 91.4%, product liquid chromatography purity 81.76% (purity is represented by teicoplanin A2 The sum of the components is the basis).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com