SnI2 doped CsGeI3 perovskite type thermoelectric material and preparation method thereof

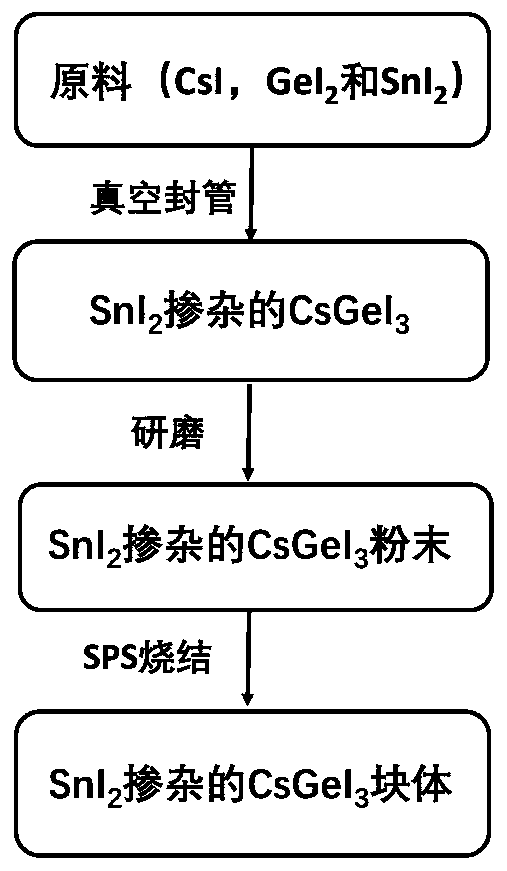

A thermoelectric material and perovskite-type technology, which is applied in the field of rapid sintering to prepare SnI2-doped CsGeI3 perovskite-type thermoelectric materials, can solve the problem that it is difficult to obtain single-phase dense bulk materials, and inorganic perovskite materials are unstable and unfavorable. Large-scale production and other issues, to achieve the effect of high block density, short cycle, and small environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

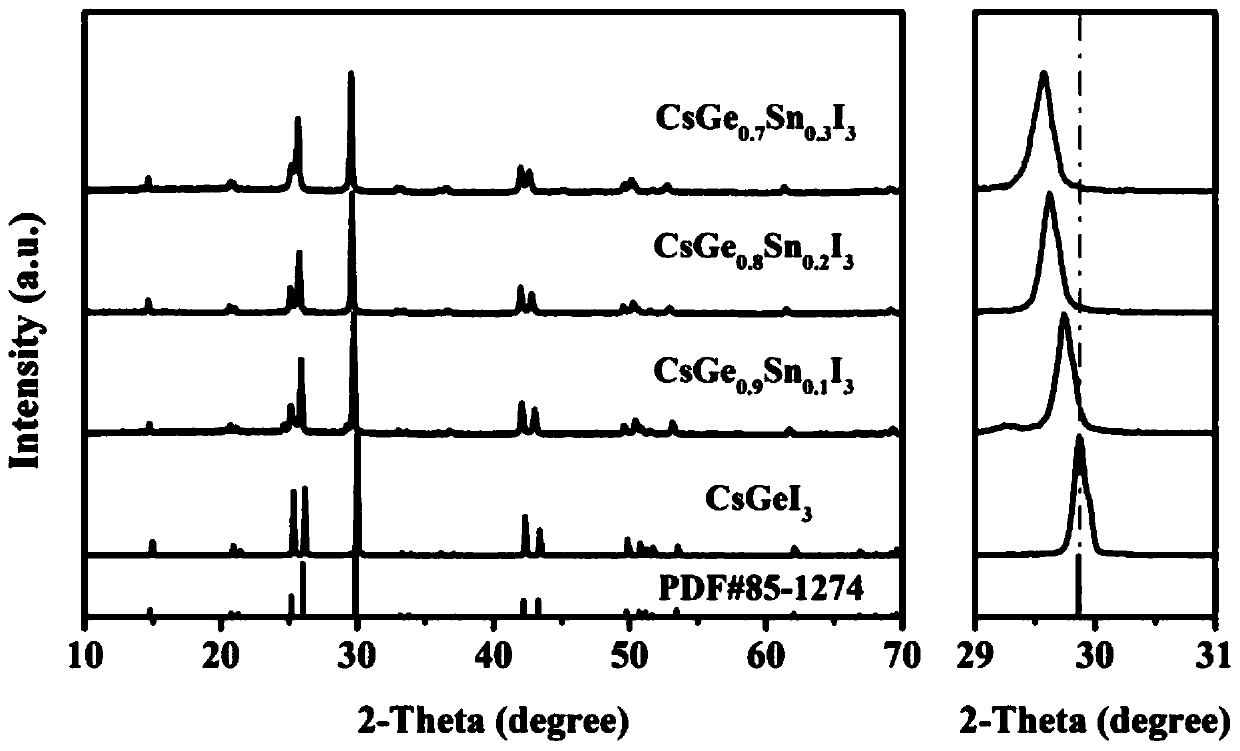

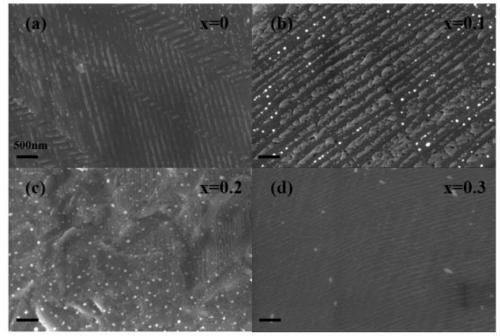

[0023] A Perovskite Thermoelectric Material 10%SnI 2 doped CsGeI 3 The preparation method specifically comprises the following steps:

[0024] (1) Powder preparation: CsI, SnI 2 and GeI 2 Weigh 1.5588g, 0.2235g and 1.7627g respectively according to the ratio of 1:0.1:0.9 and put them into the quartz tube, then vacuumize, the vacuum degree is 10 -5 Pa, put the quartz tube containing the raw material into the sintering furnace, heat it up to 490°C at a rate of 3°C / min and keep it for 24h, then cool it down to 320°C at a rate of 3°C / min; take out the obtained block in the glove box Grinding for 15 minutes, you can get 10% SnI 2 doped CsGeI 3 of powder.

[0025] (2) Block preparation: the powder obtained in step (1) is sintered by a spark plasma process, and 10% SnI 2 doped CsGeI 3 Pour 2g of the powder into a graphite mold, under the conditions of a temperature of 290°C and a pressure of 10MPa, and a sintering time of 5min, a 10% SnI 2 doped CsGeI 3 bulk material.

Embodiment 2

[0027] A perovskite-type thermoelectric material 20%SnI 2 doped CsGeI3 The preparation method specifically comprises the following steps:

[0028] (1) Powder preparation: CsI, SnI 2 and GeI 2 Weigh 1.5588g, 0.447g and 1.5668g respectively according to the ratio of 1:0.2:0.8 and put them into the quartz tube, then vacuumize, the vacuum degree is 10 -3 Pa; Put the quartz tube containing the raw material into the sintering furnace, heat it up to 490°C at a rate of 3°C / min and keep it for 24 hours, and then cool it down to 320°C at a rate of 3°C / min; take out the obtained block in the glove box Grinding for 15 minutes, you can get 20% SnI 2 doped CsGeI 3 of powder.

[0029] (2) Block preparation: the powder obtained in step (1) is sintered by a spark plasma process, and 20% SnI 2 doped CsGeI 3 Pour 2g of the powder into a graphite mold, under the conditions of a temperature of 290°C and a pressure of 10MPa, and a sintering time of 5min, a 20% SnI 2 doped CsGeI 3 bulk mate...

Embodiment 3

[0031] A perovskite-type thermoelectric material 30%SnI 2 doped CsGeI 3 The preparation method specifically comprises the following steps:

[0032] (1) Powder preparation: CsI, SnI 2 and GeI 2 Weigh 1.5588g, 0.6705g and 1.3710g respectively according to the ratio of 1:0.3:0.7 and put them into the quartz tube. After vacuuming, fill the tube with high-purity argon to seal the tube tightly. The pressure of the inert gas in the quartz tube is -1bar; Put the quartz tube containing the raw material into the sintering furnace, raise the temperature to 450°C at a rate of 2°C / min and keep it warm for 18h, then cool down to 200°C at a rate of 2°C / min; take out the obtained block and grind it in the glove box for 15min , you can get 30% SnI 2 doped CsGeI 3 of powder.

[0033] (2) Block preparation: The powder obtained in step (1) is sintered by a spark plasma process, and 30% SnI 2 doped CsGeI 3 Pour 2g of the powder into a graphite mold, under the conditions of temperature 200°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| hole mobility | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com