Finishing equipment and method for spherical sapphire

A sapphire and spherical technology, which is applied in the field of spherical sapphire finishing equipment, can solve the problems of high inconsistent rate of outer diameter, lower qualified rate of finished products, and low production efficiency, so as to avoid random rolling and mutual collision, improve the qualified rate of finished products, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

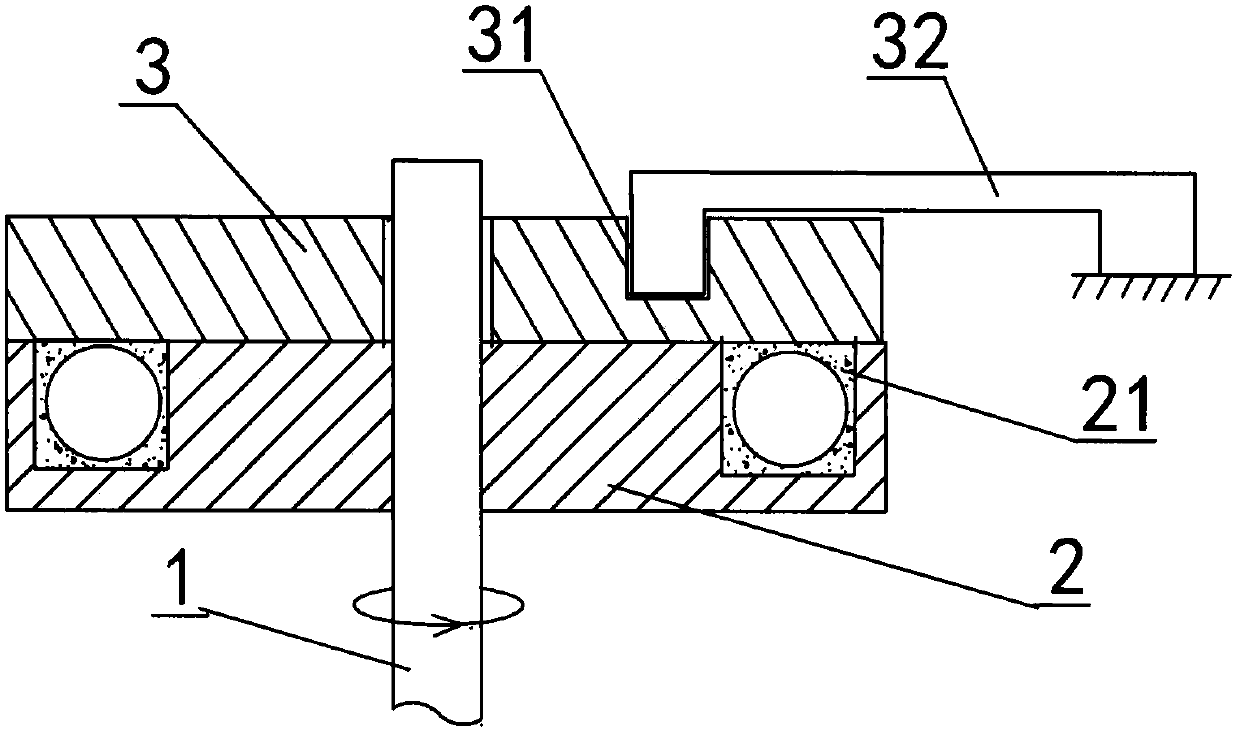

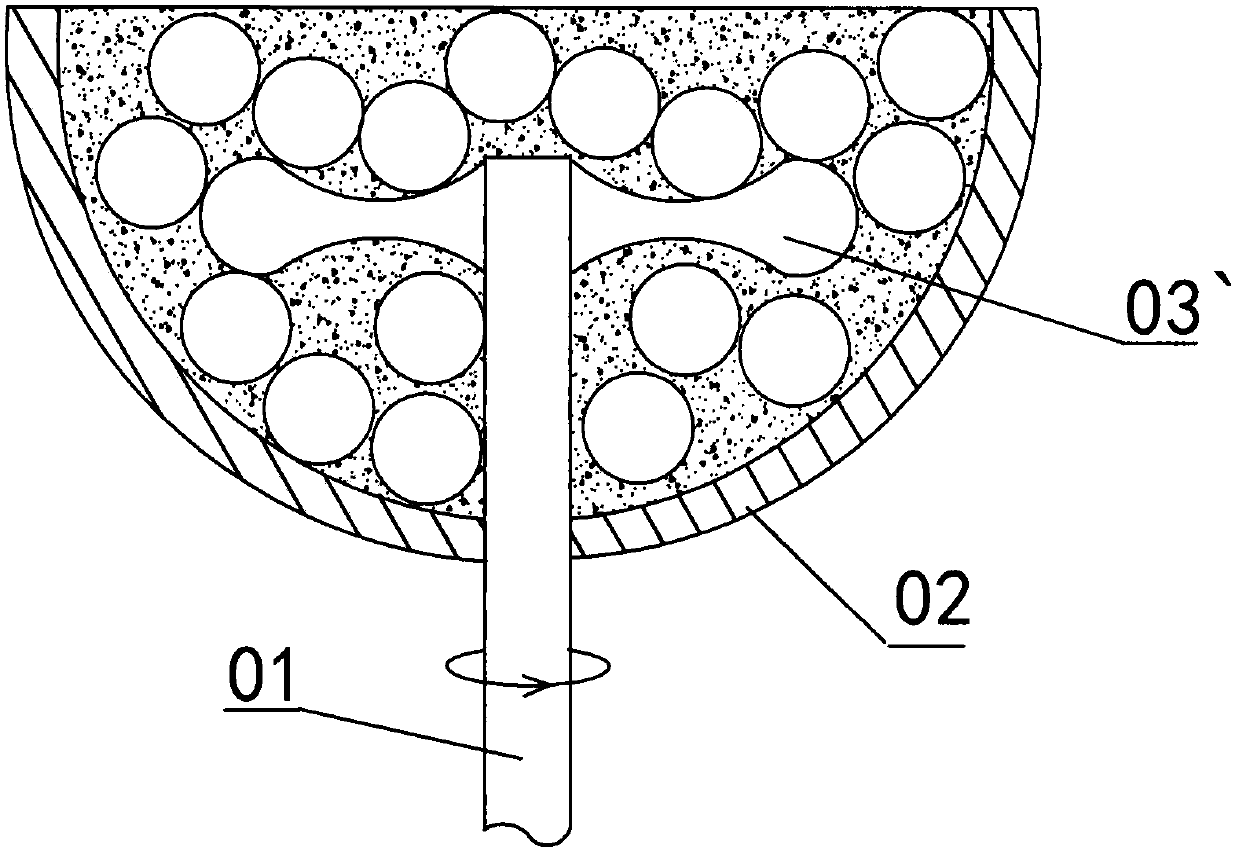

[0026] Embodiment 1: as figure 1 As shown, a finishing equipment for spherical sapphire is characterized in that it is a finishing equipment for spherical sapphire, which is characterized in that it includes a low-speed rotating shaft 1, a rotary groove disc 2 fixed on the upper end of the low-speed rotating shaft and passing through the low-speed rotating shaft. The upper end of the shaft is crimped on the fixed pressure plate 3 above the rotary groove plate. The rotating speed of the low-speed rotating shaft 1 is 95 rpm. The rotary groove plate 2 is provided with an annular groove 21 whose width and depth are slightly larger than the ball diameter 10mm required by the processed spherical sapphire technology. 50 times the diameter. Said rotary groove disc 2 is provided with a width and a depth slightly larger than the ball diameter of the processed spherical sapphire. The slightly larger in the annular groove 21 means that the width and depth of the annular groove are larg...

Embodiment 2

[0031] Embodiment 2: as figure 1 As shown, a finishing equipment for spherical sapphire is characterized in that it is a finishing equipment for spherical sapphire, which is characterized in that it includes a low-speed rotating shaft 1, a rotary groove disc 2 fixed on the upper end of the low-speed rotating shaft and passing through the low-speed rotating shaft. The upper end of the shaft is crimped on the fixed pressure plate 3 above the rotary groove plate. The rotating speed of the low-speed rotating shaft 1 is 100 rpm. Said rotary groove disc 2 is provided with an annular groove 21 whose width and depth are slightly larger than the ball diameter 4mm required by the processed spherical sapphire technology, and the central ring arc length of the annular groove is slightly larger than the processed spherical sapphire technology required ball. 100 times the diameter. Said rotary groove disc 2 is provided with a width and a depth slightly larger than the ball diameter of th...

Embodiment 3

[0036] Embodiment 3: as figure 1 As shown, a finishing equipment for spherical sapphire is characterized in that it is a finishing equipment for spherical sapphire, which is characterized in that it includes a low-speed rotating shaft 1, a rotary groove disc 2 fixed on the upper end of the low-speed rotating shaft and passing through the low-speed rotating shaft. The upper end of the shaft is crimped on the fixed pressure plate 3 above the rotary groove plate. The rotational speed of the low-speed rotating shaft 1 is 105 rpm. Said rotary groove disc 2 is provided with an annular groove 21 whose width and depth are slightly larger than the ball diameter 2mm required by the processed spherical sapphire technology, and the central ring arc length of the annular groove is slightly larger than the processed spherical sapphire technology required ball. 200 times the diameter. Said rotary groove disc 2 is provided with a width and a depth slightly larger than the ball diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com