Method for preparing nanoscale spherical Si-phase Al-Si alloy through selective laser melting

A laser melting and selective technology, which is applied in the field of metal materials, can solve the problems of low material utilization rate, small parts cannot be formed, and extremely high mold requirements, so as to shorten the production cycle and improve the fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

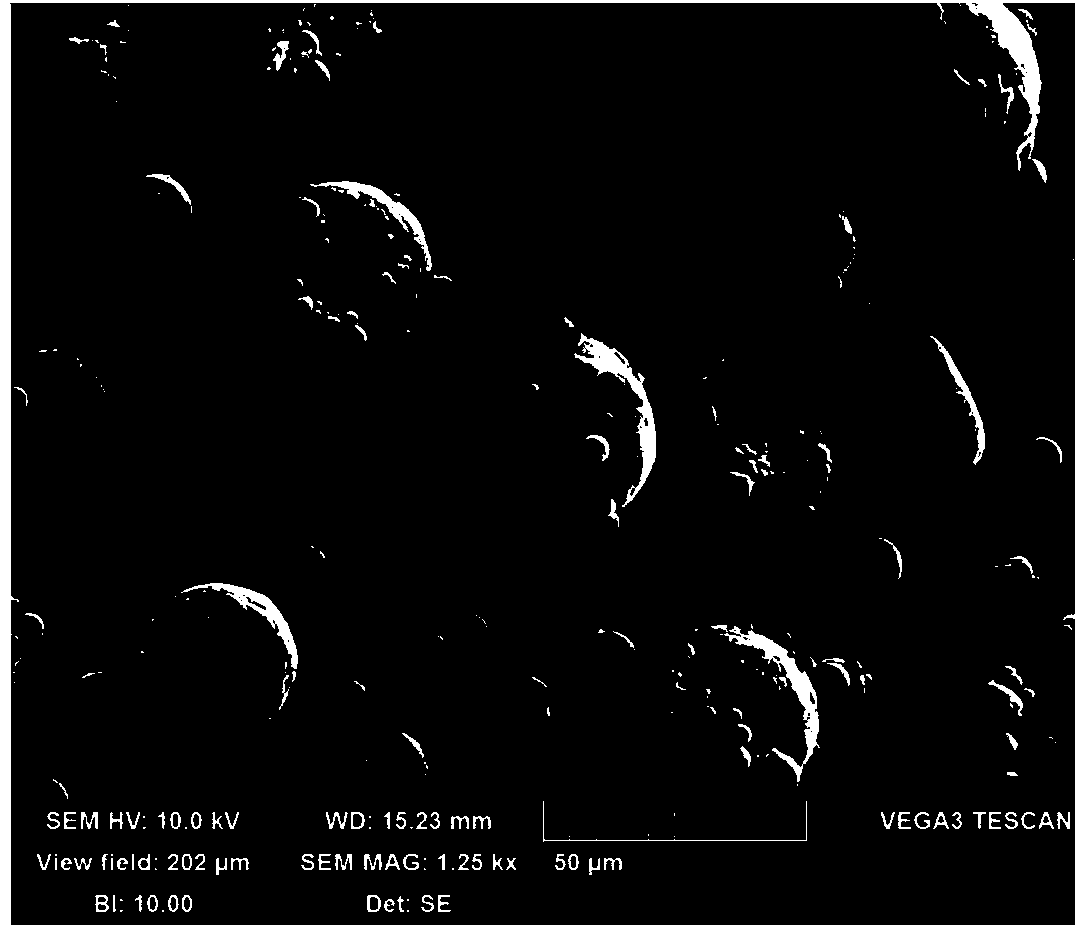

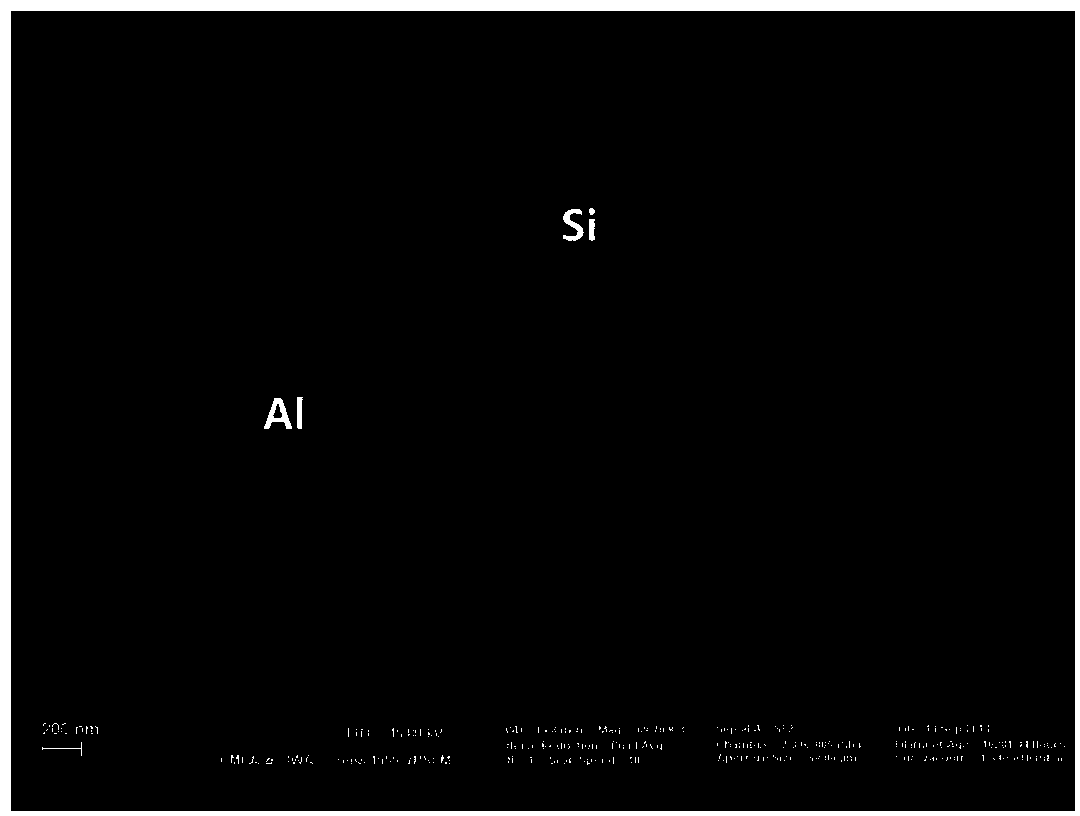

[0028] Nanoscale spherical Si phase Al-12Si alloy was prepared by SLM technology.

[0029] (1) Use the computer to design the CAD three-dimensional model of the required molding parts, and convert it into a data format (STL file) that can be cut. A 5mm support body is established at the bottom of the 3D model, the 3D geometric model and the support body are cut into several layers of 50 μm, and the process parameters are set for it, and finally imported into the SLM equipment.

[0030] (2) In the SLM equipment, the sealing device is evacuated and filled with Ar (purity above 99.99%) for atmosphere protection, the formed substrate is fixed on a liftable workbench, and the powder feeding system evenly spreads a layer of Al on the substrate. 12Si alloy powder.

[0031](3) According to the pre-set process parameters, the laser selectively scans the geometry of the cross-section of the corresponding layer. The specific process parameters are: laser power 200W, laser dwell time 80...

Embodiment 2

[0038] Nanoscale spherical Si phase Al-10SiMg alloy was prepared by SLM technology.

[0039] (1) Use the computer to design the CAD three-dimensional model of the required molding parts, and convert it into a data format (STL file) that can be cut. A 4mm support is established at the bottom of the 3D model, the 3D geometric model and the support are cut into several layers of 60 μm, and the process parameters are set for it, and finally imported into the SLM equipment.

[0040] (2) In the SLM equipment, the sealing device is vacuumized and filled with N 2 (the purity is more than 99.99%) for atmosphere protection, the forming substrate is fixed on a liftable workbench, and the powder feeding system evenly spreads a layer of Al-10SiMg alloy powder on the substrate.

[0041] (3) According to the pre-set process parameters, the laser selectively scans the geometry of the cross-section of the corresponding layer. The specific process parameters are: laser power 200W, laser dwell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com