Dispersing mixer system used in producing slurry containing carbon and producing method of slurry containing carbon

A manufacturing method and mixing system technology, applied in the direction of mixing methods, mixers, fluid mixers, etc., can solve the problems of coating voids, difficulty, poor dispersion and solubility, etc., to reduce the mixing of air bubbles and simplify degassing Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0193] (High rate discharge test)

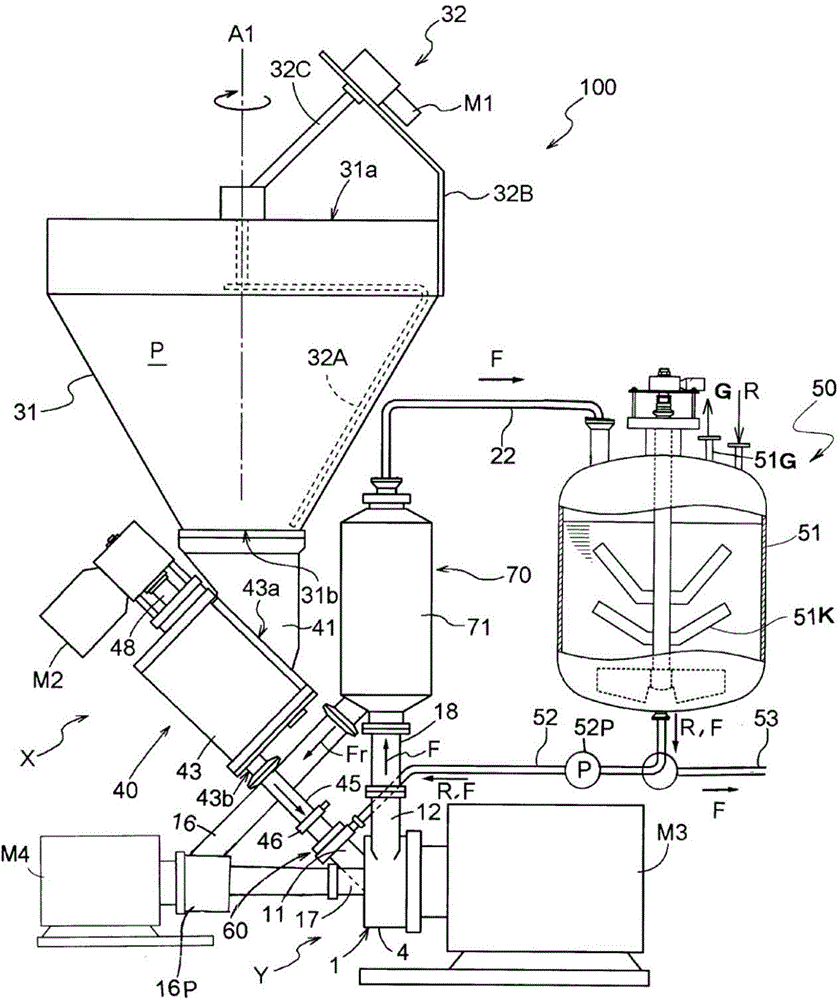

[0194] As shown in Table 1, LiFePO is used as a slurry material used in the manufacture of electrodes for non-aqueous electrolyte secondary batteries, that is, a material that absorbs and releases alkali metal ions. 4 (91wt%), carbon (carbon black (2wt%), fibrous carbon powder with an aspect ratio of 10 to 1000, and an average fiber diameter of 1 to 500nm carbon (carbon nanotubes) (2wt%)), and water-based binder (CMC (carboxymethylcellulose) (5wt%)) (solid content ratio: 31wt%), using water as the solvent R, and using the dispersion mixing system 100 equipped with the dispersion mixing pump Y to produce a slurry.

[0195] In addition, Fig. 10(a) and Fig. 10(b) show electron micrographs of the surface of the electrode coated with the carbon-containing slurry and the cross-section of the electrode (Fig. 10(a) is based on a conventional batch multiaxial mixer The photo of Figure 10(b) is a photo of the manufacturing method of carbon-containing...

Embodiment 2

[0204] (High rate discharge test)

[0205] As shown in Table 2, as a slurry material used in the manufacture of electrodes for non-aqueous electrolyte secondary batteries, that is, a material that absorbs and releases alkali metal ions, LiFePO 4 (89wt%), carbon (carbon black (1.5wt%), carbon (carbon nanotubes) with an aspect ratio of 10-500 fibrous carbon powder and an average fiber diameter of 150nm (1.5wt%), activated carbon (3wt%) ) and a water-based adhesive (acrylate (5wt%)) (solid content ratio: 37wt%), using water as the solvent R, and using the dispersion mixing system 100 equipped with the dispersion mixing pump Y to produce a slurry.

[0206] Test electrode (positive electrode) After coating each of the obtained slurries on an aluminum foil with a thickness of 20 μm and drying, the aluminum foil and the coating film were adhered and bonded by a roller press, and then heat treatment (under reduced pressure, at 150 °C for more than 12 hours) to obtain a positive elect...

Embodiment 3

[0225] As shown in Table 3, as a slurry material used in the manufacture of electrodes for non-aqueous electrolyte secondary batteries, that is, a material that absorbs and releases alkali metal ions, LiMn 0.33 Ni 0.33 co 0.33 o 2 (91wt%), carbon (carbon black (2wt%), carbon (carbon nanotubes) (2wt%) of fibrous carbon powder with an aspect ratio of 10 to 500 and an average fiber diameter of 150nm (2wt%), and a water-based binder (acrylic Esters (5 wt %)) (solid content ratio: 32 wt %), using water as the solvent R, and using the dispersion mixing system 100 equipped with the dispersion mixing pump Y to produce a slurry.

[0226] [table 3]

[0227]

[0228] Test electrode (positive electrode) After coating each of the obtained slurries on an aluminum foil with a thickness of 20 μm and drying, the aluminum foil and the coating film were adhered and bonded by a roller press, and then heat treatment (under reduced pressure, at 150 °C for more than 12 hours) to obtain a posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fiber diameter | aaaaa | aaaaa |

| Capacity density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com