Heat management system for electric locomotive traction converter

A traction converter and thermal management system technology, applied in the modification of power electronics, electrical components, output power conversion devices, etc., can solve the problem of air-cooled or water-cooled heat exchangers being large in size, unable to meet heat dissipation requirements, and device fatigue. Aging and other problems, to achieve the effect of low cost, rapid response, and improved device life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

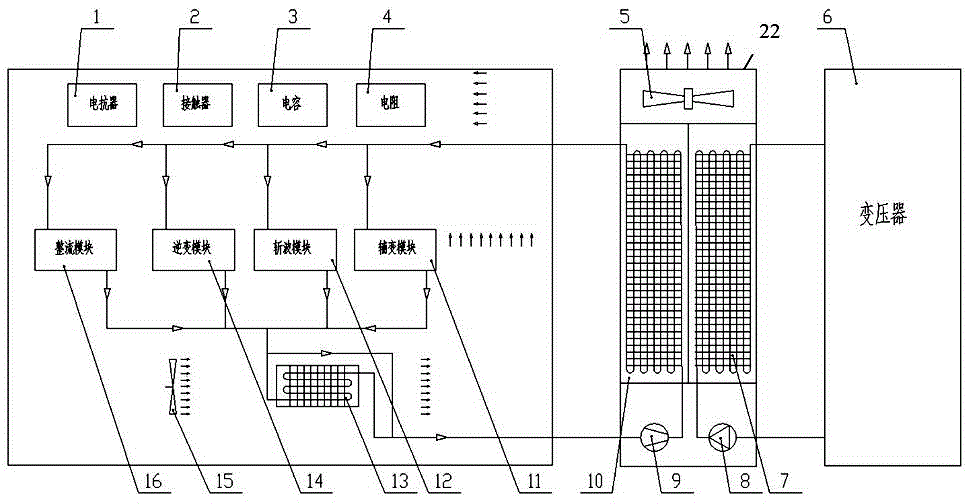

[0025] Embodiment 1: as figure 1 As shown, the thermal management system for the electric locomotive traction converter of the present invention includes a cooling tower 22, a compressor 9 and a condenser 10 installed in the cooling tower 22, and the cooling tower 22 is connected with the traction converter of the electric locomotive. converter cabinet together to form a complete system. Reactor 1, contactor 2, capacitor 3, resistor 4, auxiliary transformer module 11, chopper module 12, evaporator 13, inverter module 14, internal circulation fan 15 and rectifier module 16 are installed in the converter cabinet. The compressor 9 compresses the refrigerant in the system into high-temperature and high-pressure steam, and dissipates the heat of the system to the environment through the condenser 10; after the refrigerant becomes a normal temperature and high-pressure liquid, it is divided into two paths: one path enters the power device in the converter cabinet In the cooling dev...

Embodiment 2

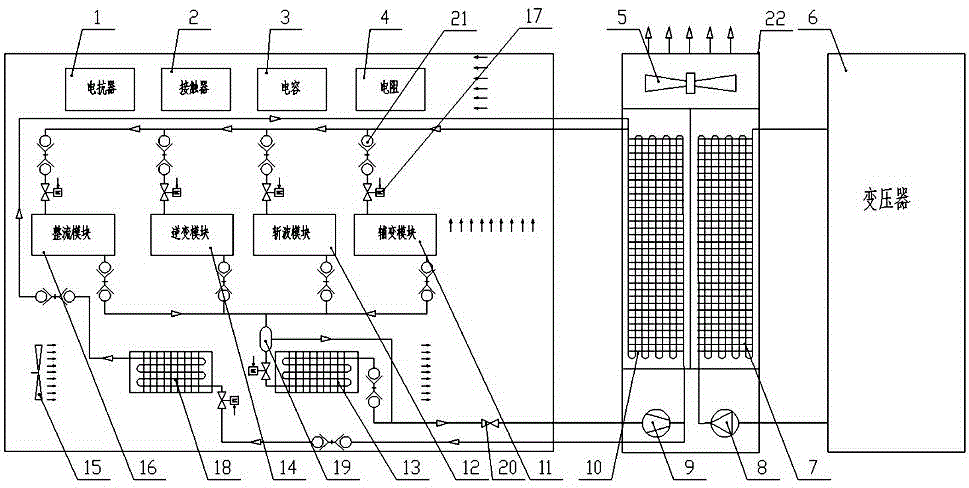

[0030] Embodiment 2: as figure 2 As shown, the thermal management system for the electric locomotive traction converter of the present invention includes a cooling tower 22, a compressor 9 and a condenser 10 installed in the cooling tower 22, and the cooling tower 22 is connected with the traction converter of the electric locomotive. converter cabinet together to form a complete system. Reactor 1, contactor 2, capacitor 3, resistor 4, auxiliary transformer module 11, chopper module 12, evaporator 13, gas-liquid separator 19, inverter module 14, internal circulation fan 15 are installed in the converter cabinet , The rectification module 16. The compressor 9 compresses the refrigerant in the system into high-temperature and high-pressure steam, and dissipates the heat of the system to the environment through the condenser 10; after the refrigerant becomes a normal temperature and high-pressure liquid, it is divided into two paths: one path enters the power device in the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com