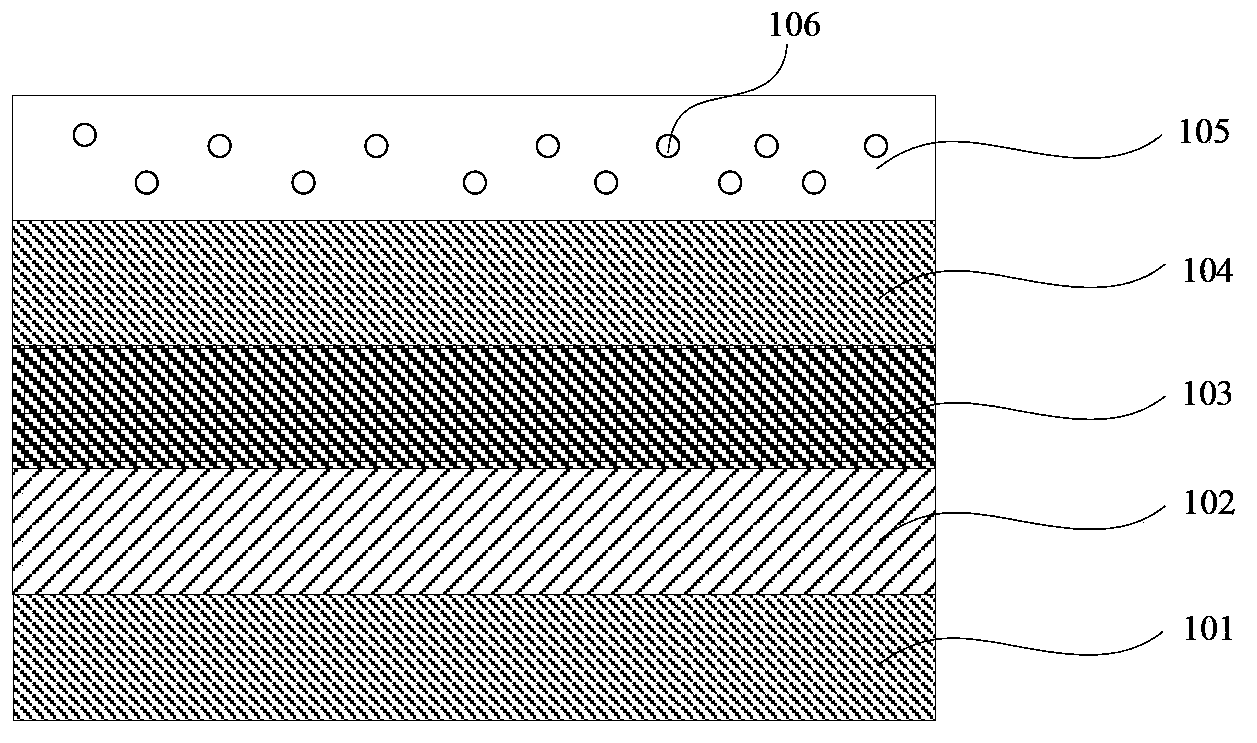

Up-converting luminescent material with ytterbium-neodymium codoped yttrium thiosilicate, preparation method thereof and organic light-emitting diode

A luminescent material and co-doping technology, which is applied in the direction of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., to achieve the effects of easy control of the preparation process, broad commercial development prospects, and promotion of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

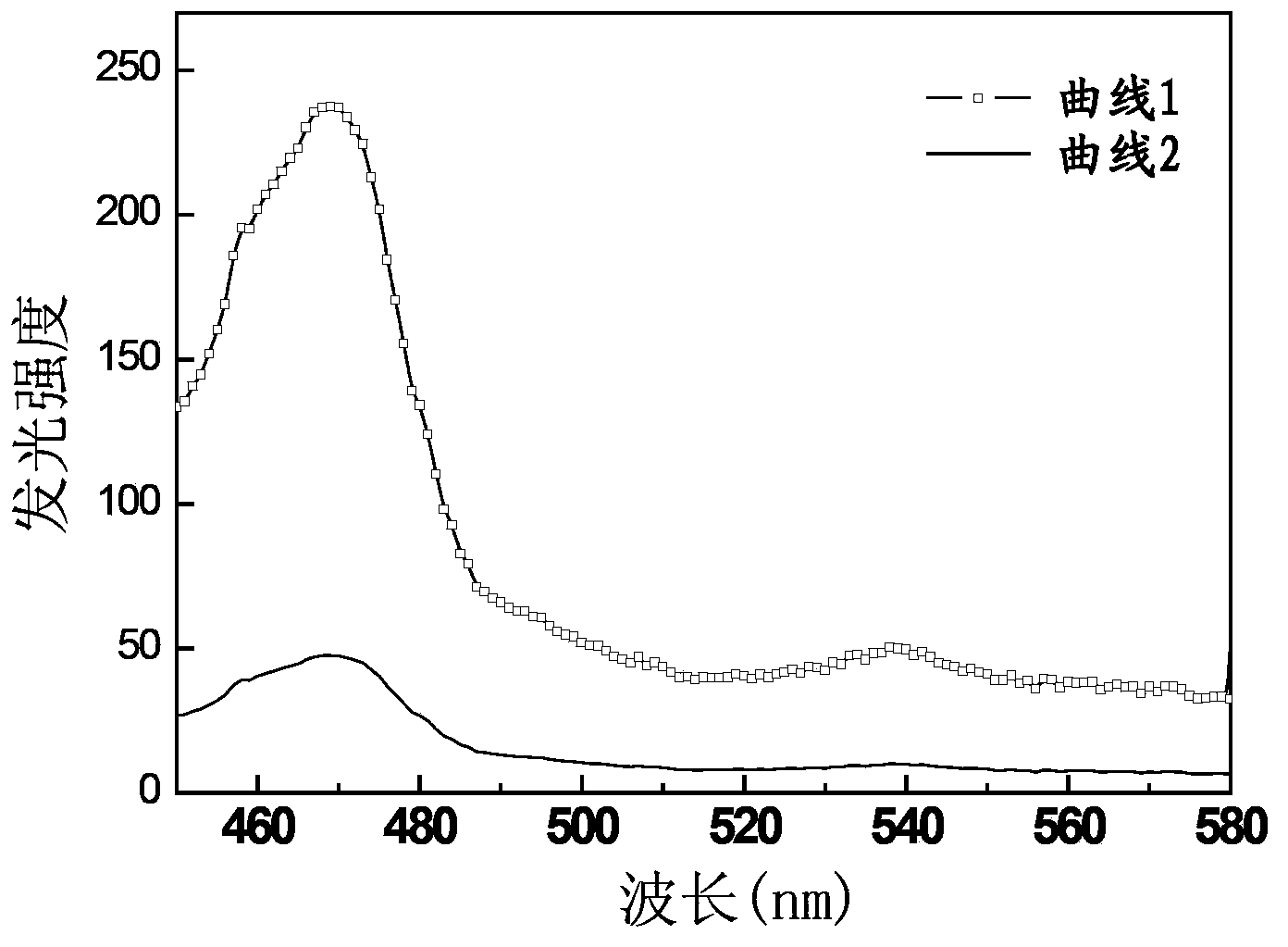

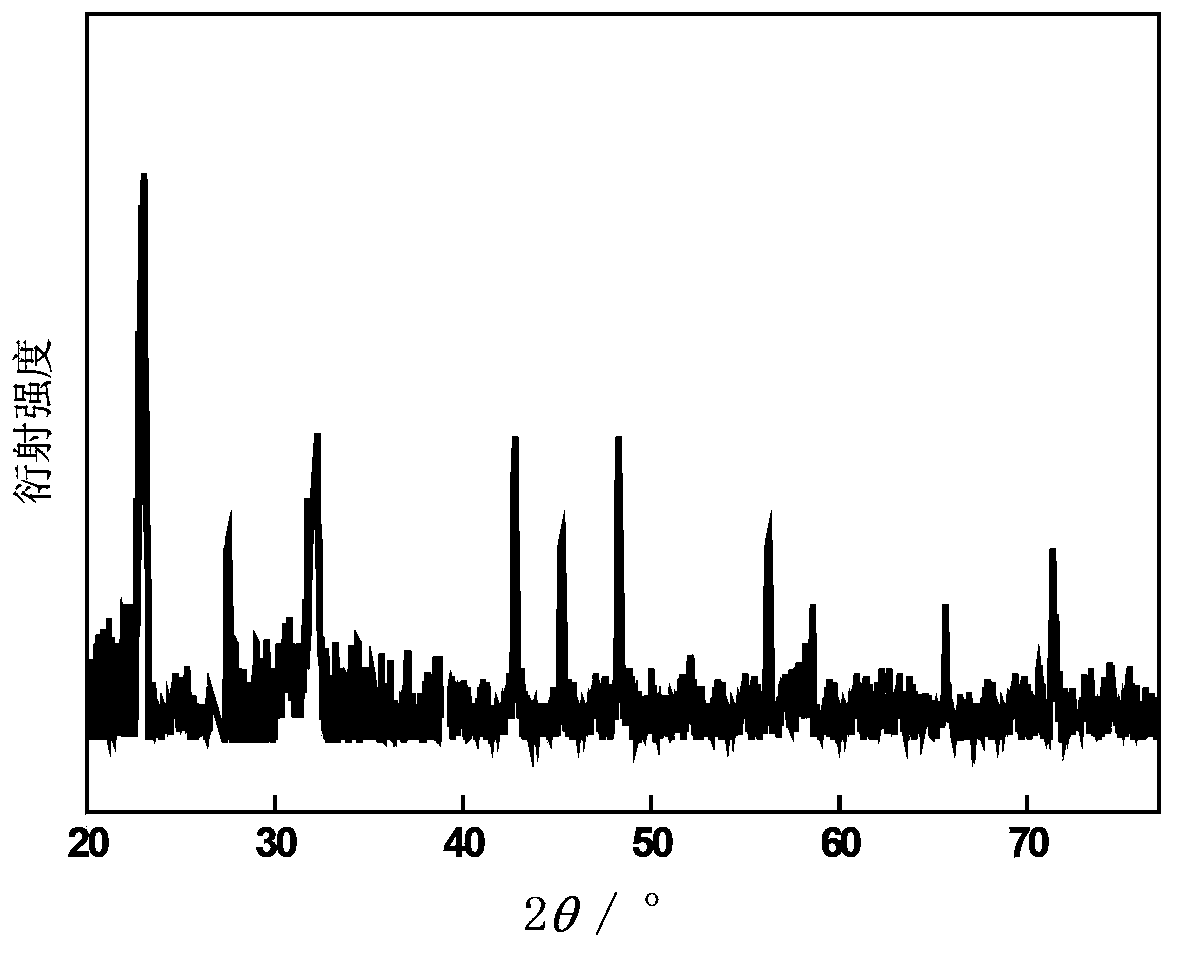

[0028] A kind of preparation method of ytterbium neodymium co-doped yttrium thiosilicate up-conversion luminescent material, the steps comprise:

[0029] (1) Weighing Y 2 S 3 , SiS, Yb 2 S 3 and Nb 2 S 3 Powder, respectively 1.97mmol, 2mmol, 0.01mmol, 0.02mmol;

[0030] (2) Dissolve the above weighed powder in excess hydrogen sulfide aqueous solution, and add polyethylene glycol as a dispersant to obtain a precursor solution. The concentration of polyethylene glycol in the precursor solution is 0.01mol / L;

[0031] (3) Import the obtained precursor solution into the atomizer of the spray dryer for spray drying, first raise the temperature of the reaction system to 1200°C, start the spray dryer, and feed argon gas into the spray dryer to control the flow rate. 5L / min; the precursor solution starts to atomize into an aerosol, enters the reaction system with the incoming argon, and generates the final product Y in the reaction system 1.97 SiS 5 : 0.01Yb 3+ , 0.02Nd 3+ U...

Embodiment 2

[0035] A kind of preparation method of ytterbium neodymium co-doped yttrium thiosilicate up-conversion luminescent material, the steps comprise:

[0036] (1) Weighing Y 2 S 3 , SiS, Yb 2 S 3 and Nb 2 S3 Powder, respectively 1.92mmol, 2mmol, 0.03mmol, 0.05mmol;

[0037] (2) Dissolve the above weighed powder in excess hydrogen sulfide aqueous solution, and add polyethylene glycol as a dispersant to obtain a precursor solution. The concentration of polyethylene glycol in the precursor solution is 0.005mol / L;

[0038] (3) Import the obtained precursor solution into the atomizer of the spray dryer for spray drying. The system temperature of the spray dryer is 500°C, and the flow rate of nitrogen gas introduced into the atomization dryer is controlled at 1L / min; The solid solution begins to atomize into an aerosol, enters the reaction system with the nitrogen gas introduced, and generates the final product Y in the reaction system 1.92 SiS 5 : 0.03Yb 3+ , 0.05Nd 3+ Up-conv...

Embodiment 3

[0040] A kind of preparation method of ytterbium neodymium co-doped yttrium thiosilicate up-conversion luminescent material, the steps comprise:

[0041] (1) Weighing Y 2 S 3 , SiS, Yb 2 S 3 and Nb 2 S 3 Powder, respectively 1.985mmol, 2mmol, 0.005mmol, 0.01mmol;

[0042] (2) Dissolve the above weighed powder in excess hydrogen sulfide aqueous solution, and add polyethylene glycol as a dispersant to obtain a precursor solution, and the concentration of polyethylene glycol in the precursor solution is 0.05mol / L;

[0043] (3) Import the obtained precursor solution into the atomizer of the spray dryer for spray drying. The system temperature of the spray dryer is 1400°C, and the flow rate of hydrogen gas introduced into the atomization dryer is controlled at 15L / min; The solid solution begins to atomize into an aerosol, enters the reaction system with the hydrogen gas introduced, and generates the final product Y in the reaction system 1.985 SiS 5 : 0.005Yb 3+ , 0.01Nd ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com