Conductive polymer-amino acid composite coating and preparation method thereof

A conductive polymer and composite coating technology, applied in electrolytic organic material coating and other directions, can solve the problems of tissue damage, nano-toxicity, induced carcinogenesis, etc., and achieve the effects of large capacitance, low electrochemical impedance, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

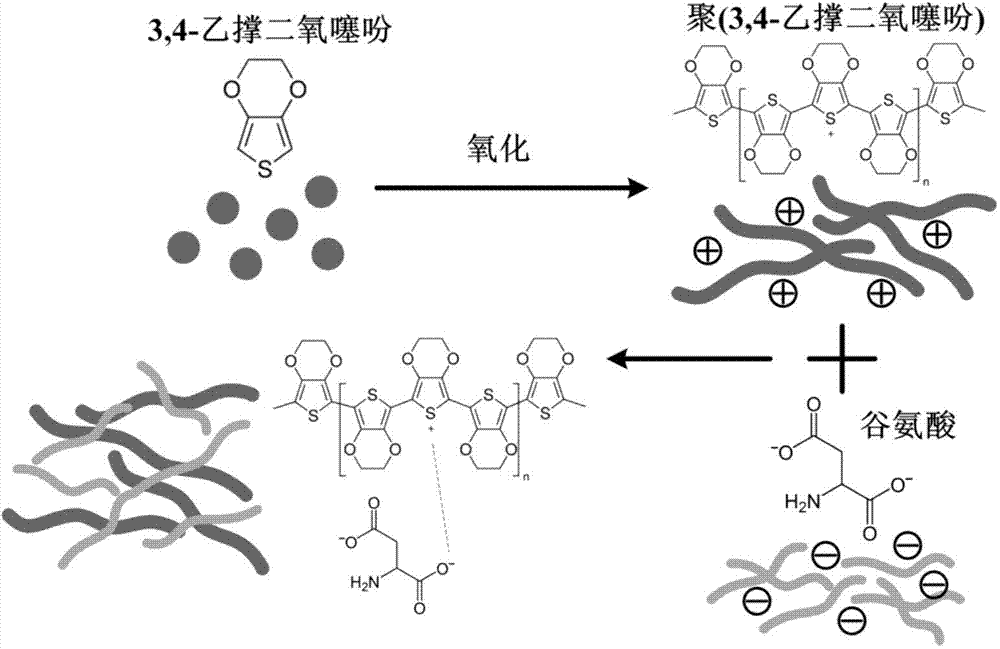

[0033] Such as figure 1 As shown, the present embodiment provides a preparation method of conductive polymer-amino acid composite coating, comprising:

[0034] 1. Weigh 0.001 mole of aspartic acid, add it to 100 ml of deionized water, and add 0.001 mole of 3,4-ethylenedioxythiophene (EDOT) monomer to the aspartic acid aqueous solution;

[0035] 2. Place the solution in an ultrasonic ultrasonic cleaner for half an hour, and stir it at a speed of 150 rpm for 4 hours to prepare aspartic acid and 3,4-ethylenedioxythiophene (EDOT) monomer concentrations of 0.01 mol / liter of electroplating solution, blow nitrogen into the electroplating solution for ten minutes, and discharge the oxygen therein;

[0036] 3. Immerse the gold electrode to be electroplated and the platinum foil counter electrode in the electroplating solution, respectively connect the positive electrode (working electrode) and the negative electrode (counter electrode) of the electrochemical workstation, use current p...

Embodiment 2

[0039] 1. Weigh 0.0005 mole of glutamic acid and 0.0005 mole of lysine, add to 100 milliliters of deionized water, add 0.0005 mole of thiophene (Th) monomer in glutamic acid and lysine aqueous solution;

[0040] 2. Put the solution in an ultrasonic ultrasonic cleaner for 1 hour, and stir it at a speed of 400 rpm for 3 hours to form electroplating with glutamic acid, lysine and thiophene (Th) monomer concentrations of 0.005 mol / liter respectively. solution, blow nitrogen into the electroplating solution for ten minutes, and discharge the oxygen therein;

[0041] 3. Immerse the conductive glass electrode to be electroplated and the glassy carbon electrode counter-electrode in the electroplating solution, respectively connect the positive and negative electrodes of the current source, use constant current electroplating, set the current density to 0.2 mA / cm2, deposit time 1200 seconds;

[0042] 4. Take out the conductive glass electrode from the electroplating solution, and rins...

Embodiment 3

[0044] 1. Weigh 0.01 mole of glutamic acid, add it to 100 milliliters of deionized water, and add 0.01 mole of pyrrole (Py) monomer to the aspartic acid aqueous solution;

[0045] 2. Place the solution in an ultrasonic ultrasonic cleaner for 4 hours, and stir for 2 hours at a rotating speed of 600 rpm to prepare an electroplating solution with a concentration of 0.1 mol / liter of glutamic acid and pyrrole (Py) monomers, and add it to the electroplating solution. Nitrogen was blown into the solution for ten minutes to discharge the oxygen;

[0046] 3. Immerse the platinum-iridium alloy electrode to be electroplated and the counter electrode of the stainless steel mesh in the electroplating solution, connect the positive and negative electrodes of the voltage source respectively, and use constant voltage electroplating. The set voltage is 0.8 volts, and the deposition time is 5000 seconds;

[0047] 4. The platinum-iridium alloy electrode is taken out from the electroplating solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com