Irradiation cross-linking polyethylene insulated low-voltage power cable preparing method

A cross-linked polyethylene, low-voltage power technology, used in cable/conductor manufacturing, conductor/cable insulation, circuits, etc., can solve the problem of large labor intensity and material waste, high melt viscosity of silane cross-linked materials, and production equipment. Large one-time investment and other problems, to achieve the effect of low extrusion temperature and mold selection requirements, significant product performance improvement, and improved one-time start-up success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following non-limiting examples illustrate the invention.

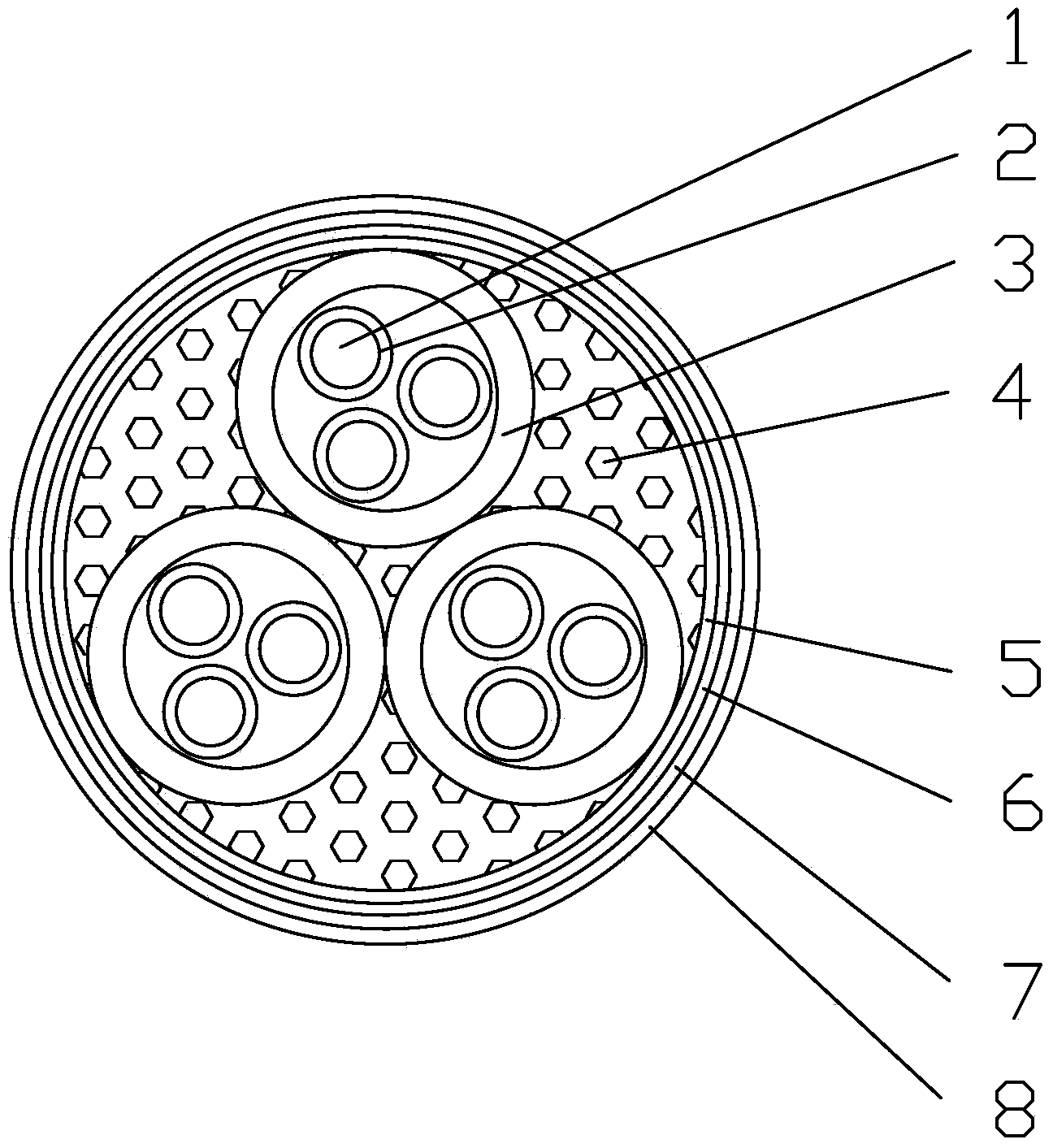

[0026] Such as figure 1 , 2 As shown, a method for preparing an irradiated cross-linked polyethylene insulated low-voltage power cable, the cable is composed of a conductor 1 and an insulating layer 2 extruded outside the conductor 1 from the inside to the outside. 3, the filling layer 4 at the gap of the cable core 3, the cabled tape layer 5 wrapped around the cable core 3, the inner sheath layer 6 extruded outside the cabled tape layer 5, the wrapped metal armor layer 7, The extruded outer sheath 8 is composed of the following steps: material selection → wire drawing → annealing → conductor stranding → extrusion and irradiation of the insulating layer 2 → cable stranding and cable wrapping → Extrude the inner sheath layer 6 → wrap the metal armor layer 7 → extrude the outer sheath layer 8;

[0027] Wherein, the conductor stranding step refers to stranding the multi-strand copper monofilaments formed af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com