Local inert gas protection device for laser deposition repair of metal parts

A laser deposition and protection device technology, applied in metal material coating process, coating, etc., can solve the problems of inability to adapt to the large size change range of repaired parts, low utilization rate of inert gas, and reduced laser repair efficiency, etc., to achieve good results. Laser repair effect, low design and manufacturing cost, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

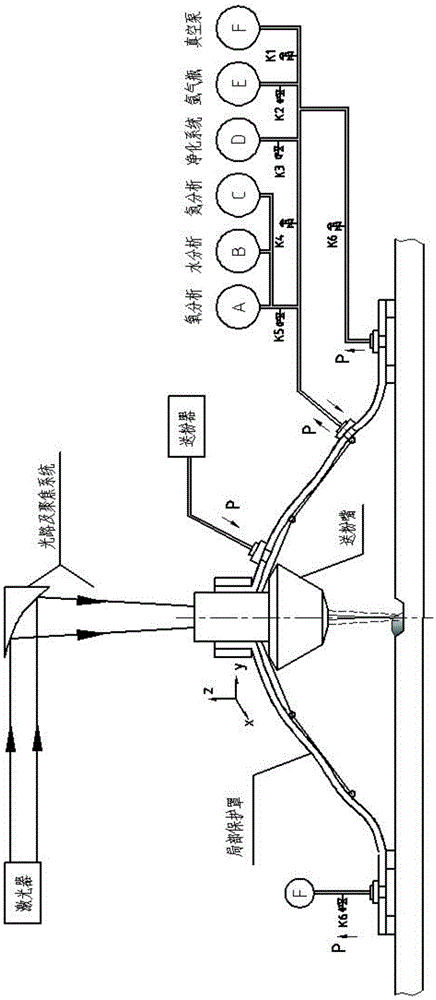

[0019] Local inert gas protection device for laser deposition repair of metal parts, which consists of fixed seat sealing ring 2, annular sealing strip 7, soft sealing cover 4, support frame 10 and gas detection sensor interface 5; the upper part of the atmosphere protection chamber uses the fixed seat sealing ring 2. It is connected with the column of the upper end motion actuator of the coaxial powder feeding nozzle 12 to form a seal; the lower part of the atmosphere protection chamber is fixed along the circumference of the part 8 to be repaired with two ring-shaped sealing strips 7 whose contours are parallel to each other; the fixed seat seal ring 2, the ring seal The strips 7 are connected by a soft sealing cover 5; a vacuum hole 9 is provided between the two annular sealing strips 7, and a first air valve and a second air valve are provided on the soft sealing cover 5.

[0020] The local inert gas protection device for laser deposition repair of metal parts as described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com