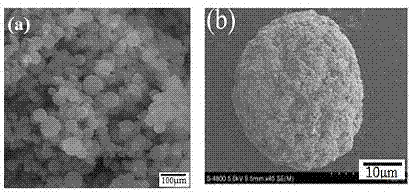

A kind of chitosan slow release fertilizer microsphere and preparation method thereof

A technology of slow-release fertilizer and chitosan, which is applied in the direction of matrix fertilizer, fertilizer mixture, layered/coated fertilizer, etc. Long-term slow-release effect and other issues, to achieve the effect of huge product market development potential, increased surface area, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) 10 weight parts of chitosan solids are put into the stirrer, adding mass fraction is 3% acetic acid solution, and the obtained mass fraction is 5% chitosan acetic acid solution; then add 50 weight parts of urea, The monoammonium phosphate of 10 parts by weight, the potassium nitrate of 10 parts by weight, the manganese sulfate of 6 parts by weight and the polyvinyl alcohol of 1.0 parts by weight, stir 2min under the speed of 1000r / min, dissolve completely and obtain the compound of chitosan and chemical fertilizer solution;

[0032] (2) Dissolving 5.0 parts by weight of sodium alginate in water to prepare a sodium alginate solution with a mass fraction of 0.5% for use;

[0033] (3) Put the composite solution of chitosan and fertilizer into the microwave reactor, add 1.0mol / L KOH solution to the composite solution of chitosan and fertilizer at a stirring speed of 200r / min, and adjust the composite solution with a pH meter. The pH of the solution=5.0;

[0034] (4) S...

Embodiment 2

[0039] (1) Put 12 parts by weight of chitosan into the stirrer, add 3% acetic acid solution in mass fraction to obtain 5% chitosan acetic acid solution in mass fraction; add 40 parts by weight of ammonium chloride , the calcium superphosphate of 20 weight parts, the potassium chloride of 10 weight parts, the magnesium sulfate of 5 weight parts, the manganese sulfate of 5 weight parts and the polyvinyl alcohol of 1.0 weight part, stir 2min under the speed of 1000r / min, completely Dissolving to obtain a compound solution of chitosan and chemical fertilizer;

[0040] (2) Dissolving 4.0 parts by weight of sodium alginate in water to make a sodium alginate solution with a mass fraction of 0.2% for use;

[0041] (3) Put the composite solution of chitosan and fertilizer into the microwave reactor, add 1.0mol / L KOH solution to the composite solution of chitosan and fertilizer at a stirring speed of 300r / min, and adjust the composite solution with a pH meter. The pH of the solution=6....

Embodiment 3

[0047] (1) Put 16 parts by weight of chitosan solids into the mixer, add 4% acetic acid solution in mass fraction to obtain 4% chitosan acetic acid solution in mass fraction; add 40 parts by weight of ammonium sulfate , the heavy superphosphate of 10 weight parts, the potassium sulfate of 20 weight parts, the ferric nitrate of 6 weight parts and the polyvinyl alcohol of 1.0 weight part, stir 5min under the speed of 500r / min, dissolve completely and obtain chitosan and chemical fertilizer compound solution;

[0048] (2) Dissolving 3.0 parts by weight of sodium alginate in water to prepare a sodium alginate solution with a mass fraction of 0.3% for use;

[0049] (3) Put the composite solution of chitosan and fertilizer into the microwave reactor, add 1.0mol / L KOH solution to the composite solution of chitosan and fertilizer at a stirring speed of 400r / min, and adjust the composite solution with a pH meter. The pH of the solution=4.5;

[0050] (4) Set the parameters of the micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com