Potash fertilizer granulation method and granules thereof

A potash fertilizer and granulation technology, which is applied to potash fertilizers, inorganic fertilizers, fertilization devices, etc., can solve the problems of high cost of melt spray granulation, irregular potash fertilizer particles, and difficult drying operation, so as to achieve high degree of automation and improve utilization rate , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

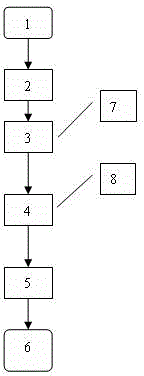

Image

Examples

Embodiment 1

[0036] 1) Weigh 90kg of potassium chloride powder, 5kg of paraffin wax, and 5kg of polyethylene wax and send them into the stirring mill for micronization and surface treatment.

[0037] 2) During the operation of the stirring mill, the temperature of the control system is 90°C, and the processing time is 60 minutes.

[0038]3) Select a screw extruder with a screw diameter of 40mm and a length-to-diameter ratio of 24:1. The barrel temperature setting range is 80~100°C, the die aperture is 3mm, the temperature is set at 90°C, and the screw speed is set It is 260r / min.

[0039] 4) Send the potash fertilizer powder into the screw extruder with various parameters set, after feeding, compressing and homogenizing, finally extruding through the die, and cutting into pellets.

[0040] 5) Cool and sieve the potash fertilizer granules to obtain qualified potash fertilizer granules: particle size 2~4mm, nutrient content 52.2, particle strength 58N.

Embodiment 2

[0042] 1) Weigh 92kg of potassium chloride powder, 4kg of glyceryl monostearate, and 4kg of stearyl alcohol and send them into a stirring mill for micronization and surface treatment.

[0043] 2) During the operation of the stirring mill, the temperature of the control system is 70°C, and the processing time is 40 minutes.

[0044] 3) Select a screw extruder with a screw diameter of 60mm and a length-to-diameter ratio of 24:1. The barrel temperature setting range is 70~90°C, the die aperture is 3mm, the temperature is set at 80°C, and the screw speed is set It is 140r / min.

[0045] 4) Send the potash fertilizer powder into the screw extruder with various parameters set, after feeding, compressing and homogenizing, finally extruding through the die, and cutting into pellets.

[0046] 5) Cool and sieve the potassium fertilizer granules to obtain qualified potassium fertilizer granules: particle size 2~4mm, nutrient content 53.4, particle strength 54N.

Embodiment 3

[0048] 1) Weigh 92kg of potassium sulfate powder, 4kg of paraffin wax, and 4kg of polyethylene glycol and send them into a vibration mill for micronization and surface treatment.

[0049] 2) During the operation of the vibration mill, the temperature of the control system is 70°C, and the processing time is 40 minutes.

[0050] 3) Choose a screw extruder with a screw diameter of 70mm and a length-to-diameter ratio of 28:1. The barrel temperature setting range is 70~900°C, the die aperture is 4mm, the temperature is set at 80°C, and the screw speed is set It is 180r / min.

[0051] 4) Send the potash fertilizer powder into the screw extruder with various parameters set, after feeding, compressing and homogenizing, finally extruding through the die, and cutting into pellets.

[0052] 5) Cool and sieve the potassium fertilizer granules to obtain qualified potassium fertilizer granules: particle size 3~5mm, nutrient content 49.7, particle strength 53N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com