Catalyst with hydrocarbon dehydrogenation catalysis function, preparation method and application of catalyst and hydrocarbon dehydrogenation reaction method

A catalyst and dehydrogenation technology, which is applied in the field of hydrocarbon dehydrogenation reaction, can solve the problem of low CNT loading, and achieve the effect of high crushing strength and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

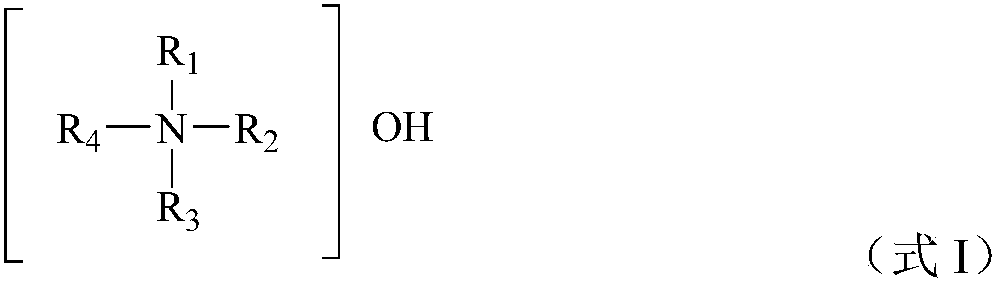

Method used

Image

Examples

preparation example Construction

[0032] According to the preparation method of the present invention, the aqueous dispersion contains a basic oxide source, at least one metal oxide source, and optionally at least one treatment agent.

[0033] The base oxide source is selected from silicon oxide, aluminum oxide, titanium oxide, silicon oxide precursors, aluminum oxide precursors, and titanium oxide precursors.

[0034] The basic oxide source may be provided in various common forms, as long as the basic oxide can be introduced into the final prepared catalyst, for example, the basic oxide source may be an oxide and / or a precursor. The oxide may be provided in the form of a sol, such as one or more of silica sol, titanium sol, and aluminum sol. The precursor can be selected according to the expected type of basic oxide.

[0035] For example, the precursor of alumina may be a substance that can be transformed into alumina, such as a substance that can form alumina through a hydrolysis condensation reaction and / or calci...

Embodiment 1-17

[0129] The following method was used to prepare the catalyst according to the conditions given in Table 2:

[0130] The nanocarbon material as the raw material is mixed with the basic oxide source and optional additives, and then the obtained mixture is placed in a sealed autoclave lined with polytetrafluoroethylene, and subjected to hydrothermal treatment under autogenous pressure . After the temperature in the autoclave is lowered to ambient temperature, open the reactor and send the obtained slurry into a strip mold for drying and optional roasting to obtain a molded body (part of the molded body is randomly selected for polishing to obtain the length The 3-5mm sample is used to determine the crushing strength and porosity, the results are listed in Table 2), the remaining molded body is crushed and then sieved to obtain the granular catalyst, its average particle size (referred to as particle size) Listed in Table 2.

Embodiment 18

[0132] The difference from Example 1 is that after mixing the nano carbon material and the crystallization mother liquor at ambient temperature (25° C.), the mixture is directly fed into the mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com