Method for preparing molybdenum-copper alloy blanks through continuous sintering

A molybdenum-copper alloy and billet technology, which is applied in the field of continuous sintering to prepare molybdenum-copper alloy billets, can solve problems such as shortening the production process, and achieve the effects of shortening the production process, improving production efficiency, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

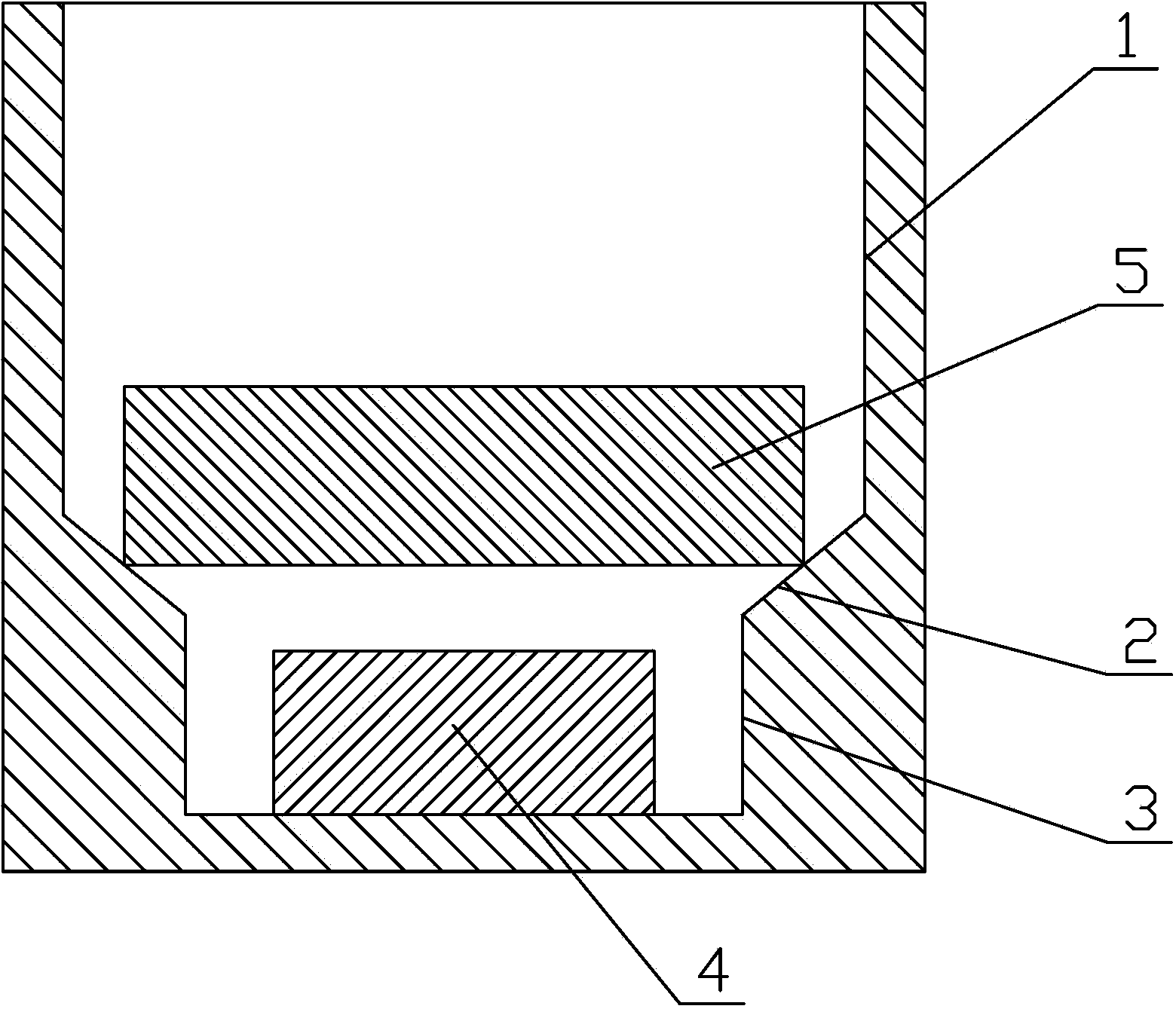

[0022] Step 1, such as figure 1 As shown, a 1.66kg copper block 4 is placed in the lower cavity 3 in the sintered crucible cavity; the sintered crucible cavity includes the upper cavity 1 and the lower cavity 3, and connects the upper cavity 1 and the lower cavity 3 middle cavity 2;

[0023] In this embodiment, the longitudinal section of the middle cavity 2 is an inverted trapezoid, and the inverted trapezoid has a base angle of 15° ° isosceles trapezoid;

[0024] In this embodiment, the cross section of the lower cavity 3 is a circle of Φ83.3 mm;

[0025] Step 2, placing 4 kg of molybdenum compact 5 with a relative density of 50% in the middle cavity 2 of the sintered crucible mold cavity described in step 1;

[0026] In this embodiment, the cross section of the molybdenum compact 5 is a circle of Φ100 mm;

[0027] Step 3. Place the sintered crucible with the copper block 4 and the molybdenum compact 5 vertically in the induction sintering furnace, raise the temperature ...

Embodiment 2

[0030] Step 1, such as figure 1 As shown, a 1.43kg copper block 4 is placed in the lower cavity 3 in the sintered crucible cavity; the sintered crucible cavity includes the upper cavity 1 and the lower cavity 3, and connects the upper cavity 1 and the lower cavity 3 middle cavity 2;

[0031] In this embodiment, the longitudinal section of the middle cavity 2 is an inverted trapezoid, and the inverted trapezoid is an isosceles trapezoid with a base angle of 45°;

[0032] In this embodiment, the cross section of the lower cavity 3 is a square with a length of 130 mm;

[0033] Step 2, placing 6 kg of molybdenum compact 5 with a maximum size of 150mm and a relative density of 60% in the middle cavity 2 of the sintered crucible mold cavity described in step 1;

[0034] In the present embodiment, the cross section of the molybdenum compact 5 is a square with a length of 150 mm;

[0035] Step 3: Place the sintered crucible with the copper block 4 and the molybdenum compact 5 verti...

Embodiment 3

[0038] Step 1, such as figure 1 As shown, a 0.61kg copper block 4 is placed in the lower cavity 3 in the sintered crucible cavity; the sintered crucible cavity includes the upper cavity 1 and the lower cavity 3, and connects the upper cavity 1 and the lower cavity 3 middle cavity 2;

[0039] In this embodiment, the longitudinal section of the middle cavity 2 is an inverted trapezoid, and the inverted trapezoid is an isosceles trapezoid with a base angle of 75°;

[0040] In this embodiment, the cross section of the lower cavity 3 is a circle with a diameter of Φ187 mm;

[0041] Step 2, placing 8 kg of molybdenum compact 5 with a maximum size of 200mm and a relative density of 75% in the middle cavity 2 of the sintered crucible mold cavity described in step 1;

[0042] In this embodiment, the cross section of the molybdenum compact 5 is a circle of Φ200 mm;

[0043] Step 3: Place the sintered crucible with the copper block 4 and the molybdenum compact 5 vertically in the indu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com