A Method for Suppressing Higher Order Modes of Gaas-Based Lasers

A laser and high-order mode technology, applied in the field of semiconductor optoelectronic devices, to achieve the effect of ensuring single-mode lasing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

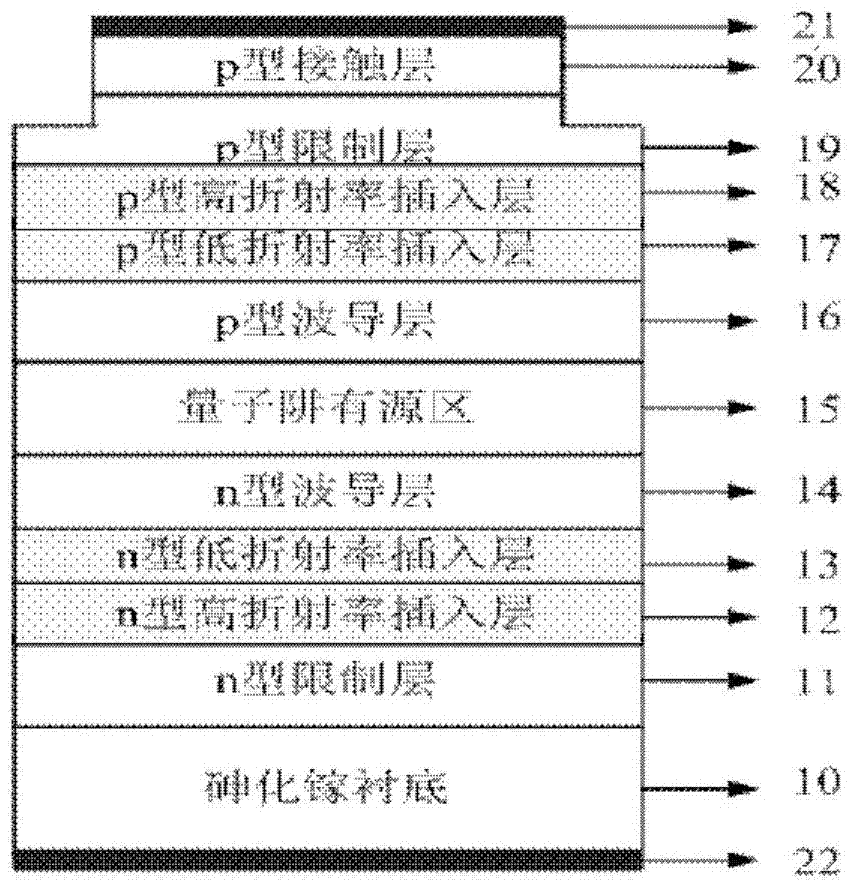

[0016] see figure 1 As shown, the present invention provides a method for suppressing GaAs-based laser high-order modes, comprising the following steps:

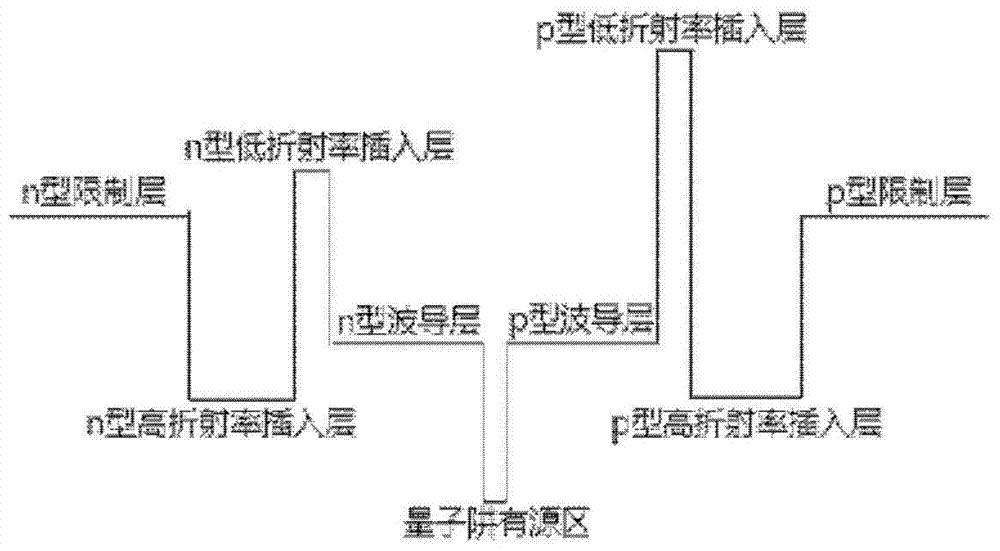

[0017] Step 1: On the gallium arsenide substrate 10, an n-type confinement layer 11, an n-type high-refractive index insertion layer 12, an n-type low-refractive-index insertion layer 13, an n-type waveguide layer 14, a quantum well active region 15, p-type waveguide layer 16, p-type low refractive index insertion layer 17, p-type high refractive index insertion layer 18, p-type confinement layer 19 and p-type contact layer 20;

[0018] Step 2: wet-etch or dry-etch the p-type contact layer 20 and the p-type confinement layer 19 in a ridge shape, and the depth of the ridge-type etching reaches the p-type confinement layer 19 . The wet etching operation is relatively simple and can be used when the etching depth is not very deep, but it is easy to cause undercutting and has a great impact on the device. If the corrosion dept...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com