Diamond cutting tool with composite structure coating and manufacturing method thereof

A technology of diamond cutting and composite structure, which is applied in the field of cutting tools, can solve the problems of weak diamond tools, and achieve the effects of reducing cutting costs, good strengthening effect, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

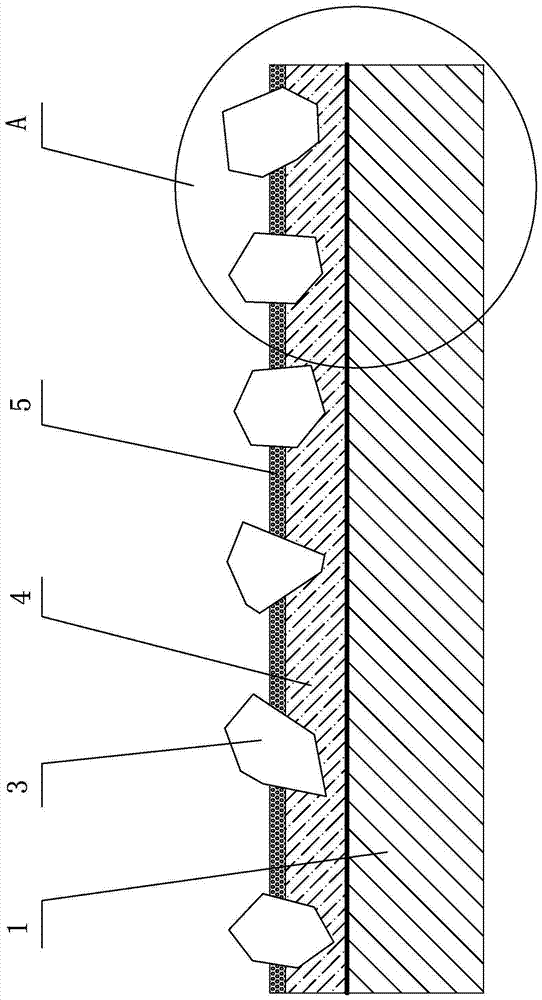

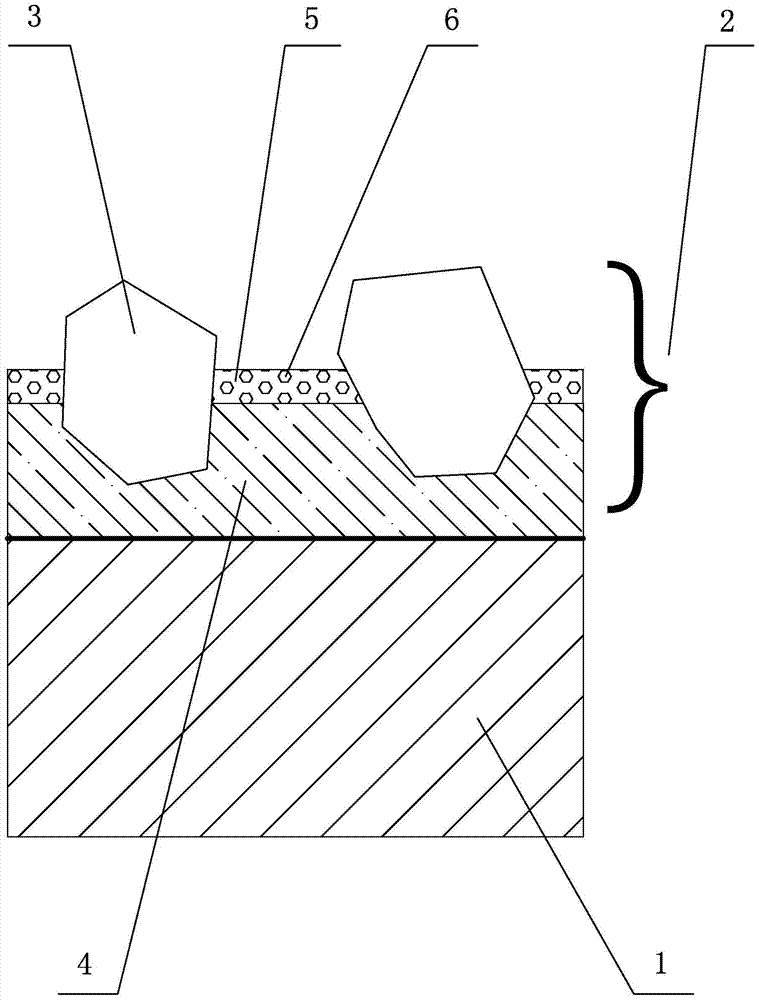

[0045] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0046] The present invention has the technical scheme of the diamond cutting tool of composite structure coating, comprises base body 1 and as the cutting edge layer 2 of cutting part, and described cutting edge layer 2 comprises the electrodeposited metal layer 4 that is affixed with superhard coarse particle 3, and described electrodeposition The deposited metal layer 4 is attached to the substrate 1 by the first electroplating method, and the high wear-resistant layer 5 is attached to the electrodeposited metal layer 4 by the second electroplating method, and the electrodeposited metal layer 4 is made of nickel sulfamate. The main salt is nickel or nickel-cobalt alloy, and superhard fine grains 6 are inlaid in the high wear-resistant layer 5. In the conventional design, the superhard coarse grains 3 expose the high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com