Method for improving yield of enzymatic hydrolysis of plant fiber materials

A plant fiber and enzymatic hydrolysis technology, applied in the direction of fermentation, etc., can solve the problems of low cellulase hydrolysis reaction speed and hydrolysis yield, etc., and achieve the effect of improving the enzymatic reaction rate and enzymatic hydrolysis yield, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the pretreatment of corn stalk

[0026] Crush corn stalks to 2-5cm, use 8% (w / w) alkali, 40% sulfide, and 1:6 (w / v) solid-liquid ratio. After idling at 60°C for 0.5h, raise the temperature To 140°C, keep warm for 1h. The corn stalks pretreated by green liquor are washed with water to remove residual chemicals, refined and squeezed dry, and used as substrates for enzymatic hydrolysis. Analyze the moisture, cellulose, and xylan content of the substrate, and calculate the recovery of cellulose and xylan.

[0027] The results show that the moisture content of corn stalks after green liquor pretreatment, refining, washing, and squeezing is 76.90%, the cellulose content is 55.39% (dry basis), and the xylan content is 25.43% (dry basis). The total recovery rate was 63.31%, the recovery rate of cellulose was 91.95%, and the recovery rate of xylan was 63.42%.

Embodiment 2

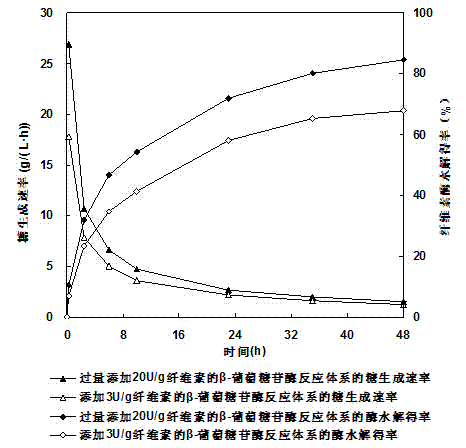

[0028] Embodiment 2: Auxiliary addition of a small amount and the influence of excess β-glucosidase on enzymatic hydrolysis yield

[0029]Take by weighing the green liquid pretreatment corn stalk 10.82g (absolute dry weight is 2.50g) of embodiment 1 respectively in 12 250mL conical flasks (enzymolysis substrate concentration 5% (w / v)), in each conical flask Add 2.5mL of 1mol / L citric acid buffer solution to cellulose, add cellulase according to the enzyme dosage of 25FPU / g cellulose, add xylanase according to the enzyme dosage of 120U / g cellulose, respectively, according to 0, 1, 2 , 3, 4, 5, 10, 15, 20, 25, 37.5, 50U / g of cellulose were added to the amount of β-glucosidase, and an appropriate amount of distilled water was added in each Erlenmeyer flask so that the total volume of water in the enzymolysis system was 50 mL, mix the reaction system well with a glass rod, cover it, and enzymolyze it in a constant temperature shaker at 150 rpm and 50°C for 48 hours. After the hyd...

Embodiment 3

[0033] Example 3: Effect of Excessive Auxiliary Addition of β-Glucosidase on Enzymatic Hydrolysis of Corn Stove Pretreated with Different Substrate Concentrations

[0034] Take by weighing respectively the green liquor pretreatment corn stalk 5.41,10.82,16.23,21.65,27.06,32.47,43.28g (absolute dry weight is respectively 1.25,2.50,3.75,5.00,6.25,7.50,10.00g) in 7 In each 250mL Erlenmeyer flask (corresponding to 2.5%, 5.0%, 7.5%, 10.0%, 12.5%, 15%, 20% (w / v) of enzymolysis substrate concentration), add 1mol / L citrate buffer 2.5mL, add cellulase according to the enzyme dosage of 25FPU / g cellulose respectively, add xylanase according to the enzyme dosage of 120U / g cellulose respectively, add β according to the dosage of 20U / g cellulose respectively -Glucosidase, add an appropriate amount of distilled water to each Erlenmeyer flask to make the total volume of water in the enzymolysis system 50mL, mix the reaction system thoroughly with a glass rod, cover the lid, and keep the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com