Preparation method of polymer foam material

A technology for foaming materials and polymers, which is applied in the field of preparing polymer foaming materials by using supercritical fluid, can solve the problems of low production efficiency, difficult industrialization, long saturation time, etc., and achieves good foaming effect, simple process and easy operation. effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

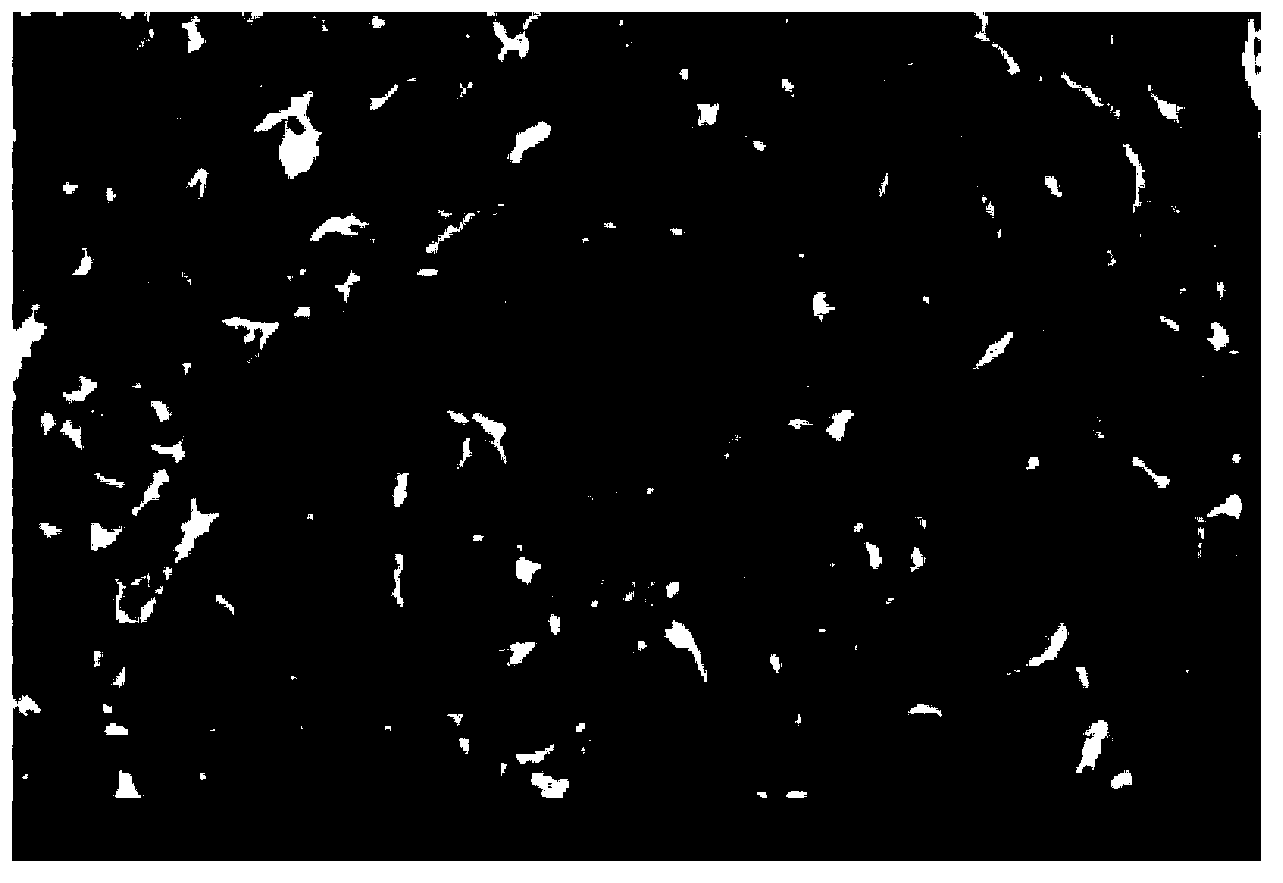

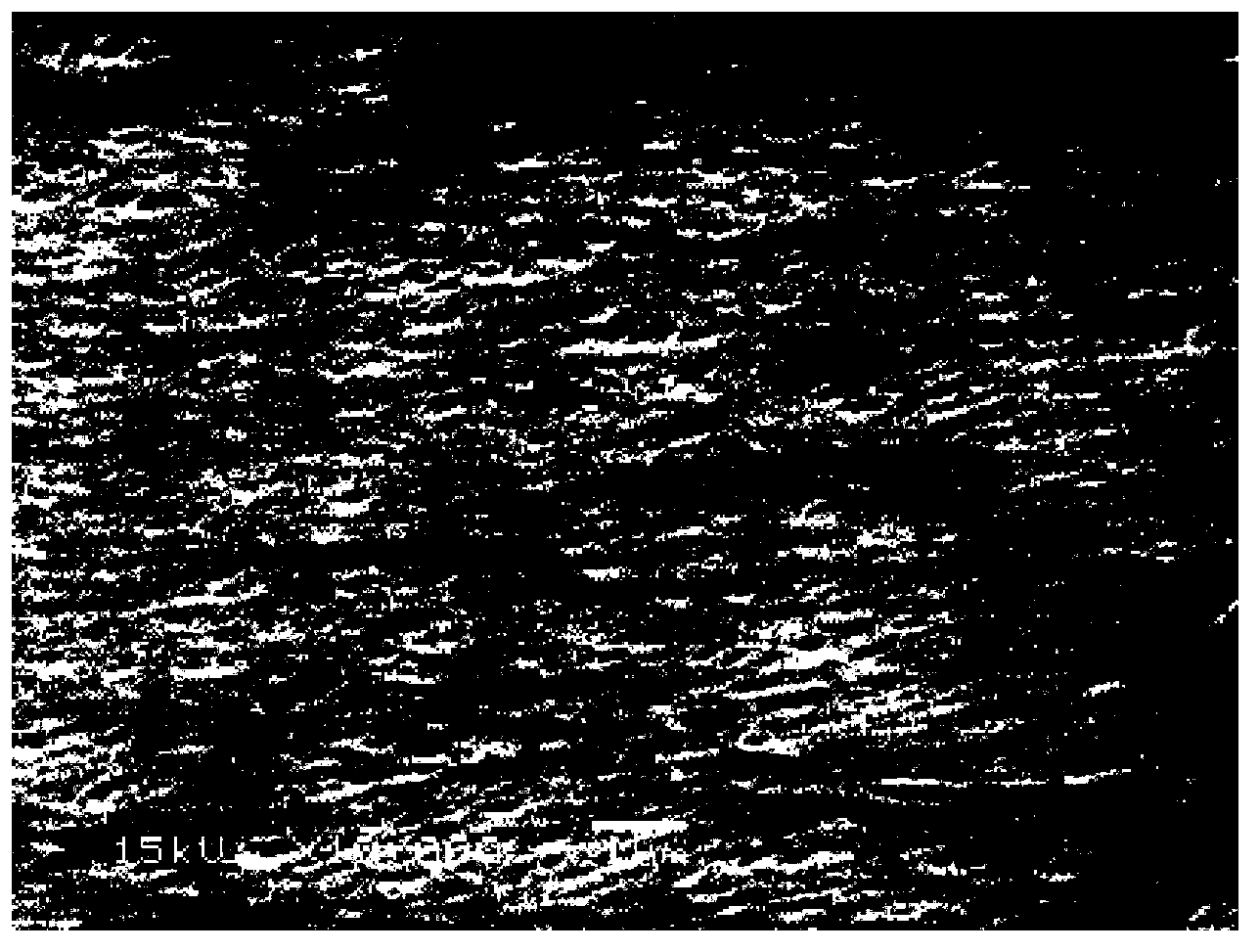

Image

Examples

Embodiment 1

[0030] Polyethylene terephthalate pellets with a number-average molecular weight of 40,000 and a melting point of 260°C were kneaded and extruded into a sheet by an extruder or injected into a sheet-like sample by an injection molding machine. The extruder used in this example Extruders can be different types of single-screw or twin-screw extruders, while injection molding machines can be different types of injection molding machines, and the mold of the extruder or injection molding machine can be any shape designed by oneself. By controlling the extrusion or injection molding process parameters (processing temperature of extruder is about 288 °C, screw speed is 25 rpm, or processing temperature of injection molding machine is about 280 °C), the juxtaposition of strongly oriented polymer samples is obtained In the high-pressure mold, the molding machine is closed, the mold is sealed, and then a small amount of carbon dioxide is filled to purge the high-pressure mold to replace...

Embodiment 2

[0034] Polyethylene pellets with a number-average molecular weight of 340,000 and a melting point of 125°C were kneaded and extruded into a sheet by an extruder or injected into a sheet-like sample by an injection molding machine. By controlling the extrusion or injection molding process parameters (processing temperature of extruder is about 152°C and screw speed is 30 rpm, or processing temperature of injection molding machine is about 145°C), the juxtaposition of strongly oriented polymer samples is obtained In the high-pressure mold, the molding machine is closed, the mold is sealed, and then a small amount of carbon dioxide is filled to purge the high-pressure mold to replace the air in the mold, and then the high-pressure carbon dioxide is filled. The temperature in the mold is set at 118°C, and the pressure is controlled at 25MPa. Swell and penetrate for 60 minutes. Then quickly release the pressure to normal pressure to obtain a polymer nanoporous foam material. After...

Embodiment 3

[0036]Polypropylene pellets with a number-average molecular weight of 240,000 and a melting point of 160°C were kneaded and extruded into a sheet by an extruder or injected into a sheet-like sample by an injection molding machine. By controlling the extrusion or injection molding process parameters (processing temperature of extruder at about 195°C and screw speed of 20 rpm, or processing temperature of injection molding machine at about 185°C), a strongly oriented polymer sample was obtained and juxtaposed In the high-pressure mold, the molding machine is closed, the mold is sealed, and then a small amount of carbon dioxide is filled to purge the high-pressure mold to replace the air in the mold, and then the high-pressure carbon dioxide is filled. The temperature in the mold is set at 150°C, and the pressure is controlled at 24MPa. Swell and penetrate for 50 minutes. Then quickly release the pressure to normal pressure to obtain a polymer nanoporous foam material. After bri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com